Green Innovation Makes our Life Better!

After more than 60 years of development, Taiwan’s textile industry has evolved from a mass production textile supplier to a textile innovator equipped with a comprehensive yet integrated value chain. While traditional textiles still have an important share in Taiwan’s textile output, the extraordinary performance achieved by local enterprises in the field of eco and multifunctional textiles has redefined Taiwan’s status in the global textile marketplace.

The core competencies of Taiwan’s textile industry lie in its R&D, technology and innovation. The industry is constantly introducing its new eco textile developments which combine high-tech, ecology, function and life aesthetics to give new definition to modern textiles.

The annual publication of Taiwan Eco Textiles is a compilation of the industry’s achievement in eco textiles for the past year. It serves as a valuable tool for those who are looking for reliable and determined textile business partners.

We truly believe that the abundant innovation of Taiwan’s textile industry can contribute to our environment and ameliorate our daily life!

Highlights

Eco-friendly

- Libolon (a label owned by LeaLea/Li Peng) created a unique Ecoflying recycle system to produce recycled PET bottle polyester fiber RePET and solution dyed nylon fiber Ecoya. Libolon is the first company in Taiwan to obtain GRS (Global Recycle Standard) certification.

- Honmyue produces bluesign approved recycled polyester fabrics and nylon fabrics. With its high-quality inkjet printing technology, the company is expanding its share in the digital print fabrics market.

- Further to its innovative yam made from coffee grounds, Nan Ya Plastics introduces Bio-PET fiber. With the material EG coming from natural renewable resources, Bio-PET can help decrease dependence on petrol and effectively reduce carbon emissions by 25% compared with the traditional PET fiber production process.

Hazardous substances free

- With the eco policy to conserve earth resources and contribute to people’s health and life quality, Everlight Chemical produces high added-value, low energy consuming and low polluting hi-tech chemicals including color chemicals, specialty chemicals, pharmaceuticals, electronic chemicals and nano-materials.

- Huntsman Textile Effects is the leading global provider of high quality dyes, chemicals and digital inks to the textile and related industries. Huntsman Textile Effects provides innovative solutions and environmentally sustainable products for the textile industry, Over 95% product achieves compliant with bluesign, ZDHC, suitable for OBKO-TEX Standard 100, RSL of Brands.

Energy-saving and carbon-reducing

- Da.Ai believes in “co-existing with earth” and maintains complete tracking records of products from materials to final articles. Da.Ai’s textile products are made from recycled PET bottles via a production process that saves 84% of energy and cuts down about 77% carbon emission compared to a traditional one.

- GAC specializes in making high performance fabrics with a clientele of over 10 leading global brands. Product offers include fabrics with advanced thermal, moisture-managing, anti-bacterial, anti-mosquito, UV protection and eco-friendly properties for outdoor and sports applications.

- In addition to high wet modulus rayon fiber Formotex and high tenacity rayon fiber Crayon, Formosa Chemicals & Fibre also offers eco and functional yarn collection Sunylon including recycled nylon yarn and cooling nylon yarn.

Testing & certification

While the world is going green, eco textile labels and certificates issued by internationally authoritative certifying bodies have become not only the quality insurance of products but quite often the minimum criteria to enter major markets like Japan, USA and EU.

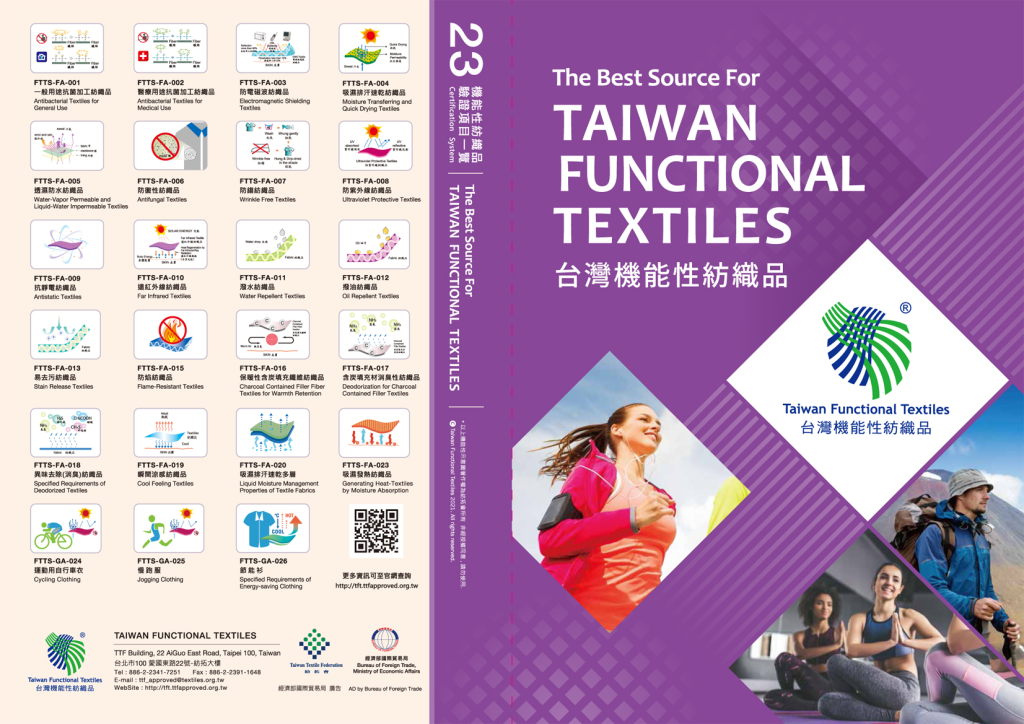

As a major textile supplier in the world, over 100 textile and apparel companies in Taiwan have received international eco labels and certificates from Oeko-Tex, bluesign, GOTS and Organic Exchange, to name a few. Testex Swiss, Bureau Veritas, Intertek, TUV Rheinland and Taiwan Functional Textiles (TFT) are well-known certifiers in Taiwan to provide testing and certification services.

Green processing

- FENC strives to do its part for environmental sustainability, actively reducing amount of energy consumed in production Processes, The Company has also set the long-term goal of zero waste production and responds to UN’s SDG12, responsible consumption and production, to ensure a sustainable production model and steadily proceeding into green industry.

- Since its establishment back in 30 years ago, Sunny Special Dyeing & Finishing Co. has devoted a multitude of resources in improving its production facilities and manufacture process including coal gasification system, bio waste water treatment system and energy recycling system. Having made remarkable achievement in water and energy conservation, the company is a paradigm in green processing.

Taiwan: The Best Sourcing Center for Functional+ Eco Textiles

Further to functionality, eco-friendliness is now a textile DNA for Taiwan’s textile industry, Whether it’s material, manufacturing process, technology, product or environment, our green-minded industrialists are working hard to make Taiwan the best source for eco and functional textiles.

Recycled PET Bottle Textile-Reclaim, Manufacture and Sell!

The journey where drinking water bottles turn into a beautiful dress starts from the recycle bin around the corner of your neighborhood. Once the bottles are collected and then crushed, they will be made into staple fibers for spinning or into filament yarns for weaving, and then are ready for end-product applications.

The production of recycled PET bottle textiles in Taiwan benefits from a thorough reclamation scheme. Consumers are encouraged to recollect used bottles. About 90,000 tons of PET bottles are reclaimed every year in Taiwan, equivalent to 4.5 billion drinking water bottles (bottle volume: 600 ml). per year.

The production and application of recycled PET bottle polyester fibers are optimized with the upstream spinning technologies for functionally, micronizatione and compound effects, and the downstream finishing technologies of weaving, dyeing, coating and lamination.

Taiwan’s position as the most reliable source for functional and ecological textiles was cup Russia further proved at various international sports events such as the 2018 FIFA’ world cup developed by Taiwan textile companies.

Recycled Nylon Textiles — Reserve & Recover Resources!

Threads and shreds from a textile factory are more valuable than you think. Through a process of sorting, screening, crushing, extruding, chipping and spinning these wastes can be transformed into clothing, home and industrial textiles.

Taiwan-made nylon textiles are renowned for their “value for money” quality, an advantage now extended. With their advanced development in recycled nylon production technology, Formosa Chemicals & Fibre, Honmyue, and Toung Loong substantially help reserve, and recover resources for the planet.

Cellulosic Fibers — from Nature, Back to Nature

Plant fibers such as cotton, linen, bamboo and pineapple leaves, seaweed and fibers such as rayon, Modal and Tencel, of which the materials are derived from plant fibers, are biodegradable cellulosic fibers. They do not generate any negative impact on environment when burned and are thus classified as typical eco fibers.

In the category of cellulosic textiles, Formosa Chemicals & Fibre, Formosa Taffeta, Acelon and Fabrix Plus have successfully developed various high-end fibers, yarns and fabrics using local eco materials.

Solution Dyed Polyester Yarn — a Best Choice for Water Saving Textiles

Among the whole production process of textile industry, the dyeing sector usually plays an important role in creating special effect for and adding value to products but is also recognized as the most environmentally unfriendly part due to the huge consumption of water and chemicals.

The production process of solution dyed polyester yarn is in line with the concept of “design for environment”. There is no need to go through any dyeing process once the weaving is done, which can therefore cut down water and energy consumption as well as effluents and waste gas generation by 70~82%.

Solution Dyed Nylon Yarn — Performance for Consumers, Protection for Earth

The development of nylon textiles has reached full bloom in Taiwan. The production of nylon filament yarn, textured yarn and finished fabrics can fully satisfy the demand of local down-stream manufacturers.

Nylon textiles have a soft and natural hand feel. They are light-weight with high tenacity. Taiwan’s development in nylon textiles ranges from CD-Nylon 6, high-shrinkage nylon 6, multi-functional nylon textiles (antibacterial, UV proof, deodorant and moisture-transferring), microporous nylon fabrics with cross section, functional nano-nylon fiber/textiles, anti-electrostatic lubricant for nylon production, to nylon non-woven fabrics.

LeaLea/Li Peng offers branded solution dyed nylon fiber Ecoya’; Formosa Chemicals & Fibre provides solution dyed nylon filament and solution dyed rayon fiber; and Formosa Taffeta, Toung Loong and Acelon are the suppliers of solution dyed nylon fabrics.

Ecological Polypropylene Fiber

Polypropylene (PP) fiber is a polymer made up of carbon and hydrogen molecules. It is biodegradable with very low environmental impact and meets the standards on environmental safety and hazardous content.

Traditionally the fiber is colored by way of solution dyeing, which is environmentally friendly in terms of saving energy and reducing carbon dioxide emission.

Honmyue has introduced a new generation dyeing method by using disperesedayes on PP textiles. The PP fiber not only can be dyed in relatively low temperature but also allowd end products to keep multiple functions.

Normal Pressure Dyeable Polyester Fiber

The molecules of a polyester polymer are strongly bound together. it requires high temperature and pressure to saturate the fibers with dye solutions. The great thing about normal pressure dyeable polyester fiber is that during the coloration, the dyeing temperature can be brought down to 95~100°C withou compromising color quality.

While the lowered dyeing temperature saves our environment from heavy use of heating energy, manufacturers at the same time can benefit from the saving on cooling time and dyeing cost. Major suppliers of this eco fiber in Taiwan include Nan Ya Plastics, Honmyue, Far Eastern New Century and Formosa Taffeta.

Solvent Spun Fiber — the Most Eco-minded Manmade Fiber

The main ingredient of solvent spun fiber is cellulose, which is derived from woods. Up to 99.5% of solvents used during the fiber manufacturing process are recoverable and reusable, and the finished products are naturally biodegradable. What’s more, less water and energy are used in the manufacture. All these environmentally sustainable characteristics win this kind of fiber a minded manmade fiber in the last 50 years. Formosa Jes made of this kind of fiber in Taiwan.

Biodegradable Textiles — Sustainable Textiles for the Earth

Biodegradable materials open a new window for the textile industry with environmental and business sustainability in mind. Biodegradable materials cause almost zero environmental impact even before and after their product lifecycle, making them a perfect example of green textiles.

APEXA® is a biodegradable polyester from DuPont. Formosa Taffeta and Nan Ya Plastics are using this material to make eco-friendly textiles.

Heavy Metal Free Polyester Fiber_Safety Guarantee

In the process of producing polyester, catalysts are often added to reduce the time required for polymerization in order to significantly increase the efficiency. The most common catalyst is a heavy metal called antimony (Sb). The European Union has stipulated in its legislation that only fabrics with an antimony content less than 30ppm are qualified for eco labels.

Heavy metal free polyester fiber shares similar properties to regular polyester fiber; moreover, it does not have the unfavorable yellowish problem which regular polyester fiber using Sb-free catalysts usually has. It can be applied to various textile products and PET bottles, and can also be recycled and reprocessed.

In Taiwan, major providers of heavy metal free polyester textiles include Nan Ya Plastics for filament yarn, Four Elements for spun porn, Formosa Taffeta and Far Eastern New Century for fabrics, and Atics for zippers.

Bio-based Textiles (Bio-PET ron and Sorona)- Reducing Petrol Consumption and CO2 Emission

Though still a petroleum-based material, about 30% of bio textile’s composition is plant-based, effectively helping reduce the consumption of fossil energy resources. The most commonly-known bio textiles are Bio-PET and Sorona®. Bio-PET is an innovative fiber from Nan Ya Plastics. Different from the traditional PET fiber production, the material EG used to make Bio. PET fiber is from natural renewable resources, successfully reducing the dependence on petrol and effectively lowering 25% of carbon emissions.

Sorona® is a breakthrough made by DuPont in renewably sourced material for textiles. With 37% of its basic raw material drawn from natural sugar, the production process of Sorona” reduces 30% of energy consumption and 63% of CO, emission compared with that of nylon chips, making it an ideal choice for eco textiles.

Nan Ya Plastics, Toung Loong, Far Eastern New Century and Formorsa Chemicals & Fibre, among others, are the leading producers of bio-base! textiles in Taiwan.

Instant Cooling Fiber — Feel Cool in the Summer

The performance of instant cooling textiles comes from the mineral compound powders which possess the Properties of slow heating and quick cooling. The fibers with mineral powders added help wearers drive out body heat and have a comfy chilling feel.

When wearers are in instant cooling clothing, A/C temperature setting can be raised by 2°C, which helps save energy and cut carbon footprint.

Toung Loong, Da.Ai, Formosa Chemicals & Fibre, Formosa Taffeta, Four Elements, Nan Ya Plastics and GAC are all innovators in this sector.

Organic Textiles — It’s Green, It’s In!

Organic cotton refers to the cotton cultivated on fields over 3 Years free from any use of pesticides and chemical fertilizers. No insecticides, herbicides and defoliators are allowed in the growth of organic cotton. It is One of the best material options for responsible brands and enterprises to realize their commitment to protect our planet.

The organic cotton yarns made by Formosa Chemicals & Fibre, Formosa Taffeta and Far Eastern New Century have passed certification from international professional bodies such as IMO of Switzerland and Control Union of the Netherland.

Cotton and Wool – Natural and Sustainable

Cotton and Wool are natural, renewable and biodegradable. Cotton has been used to dress and protect mankind for at least 7,000 years. Today cotton textile is a global industry. After 30 years of efforts and thanks to the new agritechnology, American cotton farmers are now able to increase water-use efficiency by 80% and decrease energy consumption and pesticides use by 31% and 50% respectively.

To ensure people can continue to reap cotton’s natural benefits now and in the future, U.S. cotton industry is committed to producing cotton in the most sustainable manner possible, taking into account the economy, environment and social responsibility.

80% of the global merino wool used in apparel is produced in Australia, where the production for the year 2017/18 reached 338,000 tons. The properties of Australian Merino wool plus its eco friendliness make it a most suitable apparel material for eco-conscious consumers. And the Merino Wool system introduced by The Woolmark Company further provides a series of functional fabric collections for sports activewear.

Charcoal Fiber — Keep Warm in the Winter

Once through fire and flame, bamboos and coconut shells are transformed into porous charcoals. The charcoals are further grounded into nano-sized powders, mixed well with polymers and then undergo a series of fabrication process-from spinning, false twisting to weaving—before ready to be made into a variety of textile products. Formosa Chemicals & Fibre, LeaLea/Li Peng, Nan Ya Plastics and Acelon are Taiwan’s major manufacturers of charcoal fiber.

Nan Ya Plastics transforms coffee grounds via carbonization process into coffee fibers for a wide range of applications. Formosa Taffeta has launched collections of bamboo charcoal and coconut shell charcoal fabrics. Atics wses bamboo charcoal fiber to make zippers and accessories.

Smart Textiles — Sense and React

Smart textiles, which offer new function and performance by adding advanced technology on traditional textile techniques and materials, is a fast growing market sector for the textile industry.

Smart textiles offer wide-ranging applications such as products combining electronic technology to provide entertaining function, adopting biological monitoring technology to provide healthcare function, incorporating light emitting technology to create human security function, and applying solar power storage system to generate mobile energy.

Eco Composite Textiles — New Opportunity for Eco Textiles

Composite materials are materials formed or engineered from two or more constituent materials which have considerably different functional and physical properties. Composite materials play a significant role in the development of textile application.

Eco friendly composite textiles providers in Taiwan include yarn producers LeaLea/Li Peng, Nan Ya Plastics, Far Eastern New Century and Four Elements, and fabrics maker Da.Ai.

Green Business is Good Business

The worldwide green wave directly and indirectly generates great demands for eco friendly products, evoking the thriving research and development of green textiles in the global market. And eco textiles are emerging from a new wave to a mainstream in the industry. With the uprising awareness of the deteriorating environmental conditions, it can be expected that ecology will finally come first before economy for both the industry and consumers.

The forming of the ZDHC (Zero Discharge of Hazardous Chemicals) group and its Joint Roadmap illustrates how and what the textile, apparel and retailing industries are going to do to reduce and even eliminate the negative impact caused across the supply chain to the environment and human health.

Under the gloomy economic climate, green remains to be the color of money as green products proved to be good for business. Eco friendly practices are found to create jobs and generate business opportunities.

Eco textiles and its related services are now also the appealing focus of international textile exhibitions. TITAS (Taipei Innovative Textile Application Show), organized by Taiwan Textile Federation, have special sections devoted to eco textiles and relevant certification services.

Get Certified — a Ticket to the Global Market

textile industry around the world has a reorientation of thinking about the environment.When ecology finally does not have to come beliind economy,many textile enterprises have their green policy and green actions reinforced as a marketing force for elevating corporate/brand image and increasing sales performance as they cope with the inconvenient truth of global warming.

While the world is going green, eco textile labels and certificates issued by internationally authoritative certifying bodies have become not only the quality insurance of products but quite often the minimum criteria to enter major markets like Japan, USA and EU.

As a major textile supplier in the world,over 100 textile and apparel companies in Taiwan have received international eco labels and certificates from Oeko-Tex®, bluesign”, GOTS and Organic Exchange, to name a few. Testex Swiss, Bureau Veritas, Intertek, TUV Rheinland and Taiwan Functional Textiles (TFT) are well-known certifiers in Taiwan to provide testing and certification services.