In a major leap toward sustainable textile production, Kingfull Machinery has launched its latest generation of LowWater dyeing systems, offering an environmentally friendly and cost-effective solution for the global dyeing industry.

The new technology was prominently showcased at the ITCPE 2025 exhibition in Guangzhou, where the company attracted significant attention from international buyers and industry professionals.

As one of the leading exhibitors at ITCPE 2025, Kingfull Machinery demonstrated its commitment to innovation by presenting its most advanced dyeing machines, including JYF-06DB (Vertical Setting & Steaming Integrated Machine) and JYF-06NB (Satellite Heavy Load Uniform Padder). These machines reflect the company’s dedication to reducing environmental impact while maintaining the highest standards of quality and efficiency.

Compared to traditional dyeing processes, the LowWater system achieves remarkable performance improvements:

Up to 90% less water consumption

- 50% energy savings

- 30% cost reduction

- 30% less workshop space required

- 50% increase in production capacity

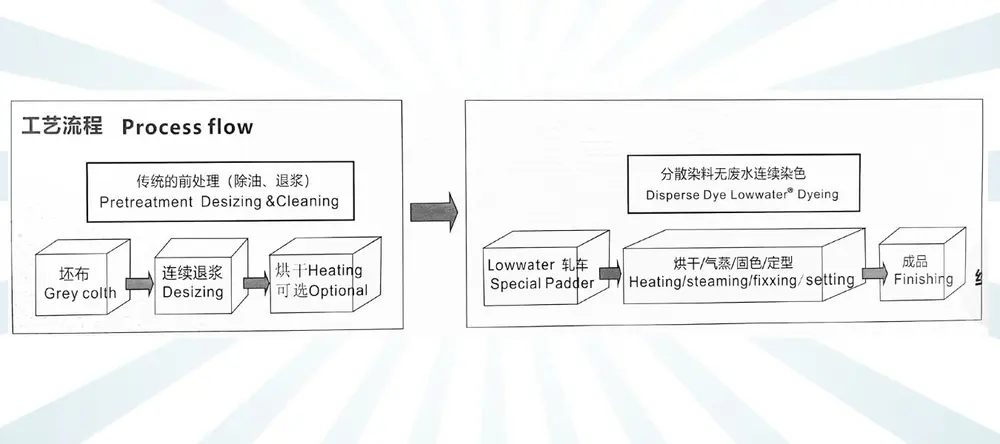

At the heart of this innovation is a closed-loop, low-liquor dyeing method that enhances dye penetration and eliminates the need for washing after dyeing. This system ensures consistent colour output, reduces hydrolysis, and dramatically lowers chemical and water waste. The pressure adjustment mechanism allows independent control of rollers on both sides and the center, achieving pressure levels up to 500N/cm—a key factor in maintaining colour uniformity across various fabric types.

Kingfull’s LowWater technology sets a new benchmark for eco-efficient dyeing solutions and confirms the company’s role as a technology leader in the global textile machinery market. With its successful presentation at ITCPE 2025, Kingfull Machinery is poised to expand its global footprint and contribute meaningfully to greener, smarter textile manufacturing.