Solution

- Martindale for Wood, 2- or 5-station

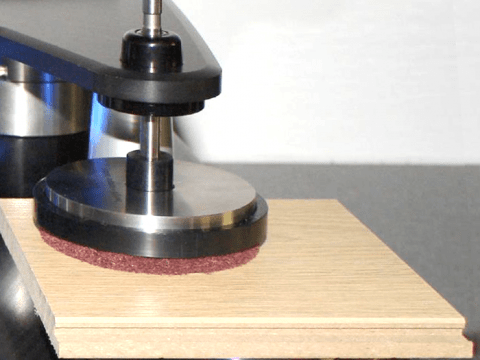

- Specimen mounting plate, 3M Scotch-Brite abradant and holder, spindle and spacer, 4 N or 6 N

Benefits

- Standards-driven repeatable testing for abrasion

- Consistent quality

- Scratch and micro-scratch resistance evaluation for natural and man-made surface materials

Requirement

The use of natural materials has long been a unique selling point across many consumer product lines. Real wood is seen as having particular value in terms of quality and luxury in furniture and vehicle design as well as many components in very diverse industries.

In addition to test standards focusing on structural safety to functional performance, an additional important consideration is how a wood finish will look throughout its life in service. Natural products may have advantages in terms of visual or tactile appeal but in most applications, durability must also be guaranteed to match their manufactured alternatives.

In use, surfaces such as table-tops and flooring will be subjected to various types of wear and tear—most notably, abrasion—resulting in a deterioration in surface appearance.

Global brands in both solid wood and laminate products implement micro-scratch and general surface abrasion testing to a range of standards. International standards and tailored internal test methods enable these companies to ensure a consistent level of quality independent of manufacturing location.

Solution

The Martindale abrasion tester was further developed for use on wood in collaboration with Institut für Holztechnologie (Institute for Wood Technology) Dresden, Germany. Its use is specifically required in test standard PD CEN/TS 16611: Furniture. Assessment of the surface resistance to microscratching.

As abrasion is defined as the surface wear caused by rubbing with another material, the principle of abrasion testing is to ‘rub’ the test sample surface with an abrasive material, under certain conditions.

The Martindale implements circular motion to provide multi-directional rubbing, delivering results more representative of the actual end-use than other methods in the market, which scratch the surface in a straight line only. The motion is that of multiple ‘Lissajous figure’ curves, created as the tester cycles through the rubs.

Despite the complex motion of the Scotch-Briteᵀᴹ abradant pad on the sample, the tester itself is easy to use – ensuring consistent and repeatable results. TestWise Touch software provides a simple-to-use touchscreen for optimum efficiency.

Quick set up of tests is enabled by a standards-driven interface, where the user is guided explicitly through the process, thus requiring minimal training. Once the test has been completed, the surface of the sample is visually inspected and graded for level of damage.

A range of sample thicknesses may be tested, making the Martidale capable of testing thin, decorative High-pressure Laminate (HPL) through to deeper, solid wood specimens such as countertops. A Specimen Mounting Plate (SMP) and an interchangeable spacer deliver test space flexibility.