Interview with Laila El Gammal , Nobeltex President and Nayle El Tawil, Nobeltex Vice President

By Behnam Ghasemi – Kohan Textile Journal

Nobeltex is part of a family-owned group of companies representing first-class international suppliers of textile machinery & accessories, air conditioning systems and fire protection systems in the Egyptian Textile Market…

Denim has been used in the United States since the mid-19th century, Denim initially gained popularity in 1873 when Jacob W. Davis, a tailor from Nevada, manufactured the first pair of rivet-reinforced denim pants for work.

Egypt is an important producer of Denim Fabrics and Denim cloth in Mena region, please let us know more details about Denim Sector in Egypt and its history?

Denim fabrics and jeans have started to be a fashion symbol around the globe, but the DENIM manufacturing process has not started in Egypt until the 1980s when the demand for jeans started to grow, Egypt was seen as a production hub haven due to various reasons such as the quality of Egyptian cotton and cheap labour and not to mention the facilities that the Egyptian authorities gave back at the days to assure investors and making investments in Egypt more lucrative like lowering taxes, offering energy and water at a low rate.

Which kind of machinery and technologies you are offering to DENIM fabric and clothing manufacturers in Nobeltex company?

In order to answer that question, you need to know the process of manufacturing denim in General.

1. RIETER: Cotton fibre is spun into yarn (For that we have RIETER machines). For denim yarns various types of yarns are applied and Rieter provides the full range, from OE yarn, standard ring yarn, compact ring yarn and special yarns, such as slub, core and dual-core yarns. These yarns are used in the production of denim fabric production according to style and application.

2. SSM: SSM have the machine XENO -AC produces the special yarn to produce stretch Denim.

3. SMARTEC: Some of the yarn is dyed, (for that we have Rope dyeing machines from a Chinese

company called SMARTEC & sheet dyeing machines from an Indian company called JUPITER and the difference between both machines are in quantity and quality of production, rope dyeing machines are always higher)

4. ALLWIN: Some left white (they can be bleached using our yarn dyeing machines from FONGS called ALLWIN).

5. JUPITER: The yarn is then sized using sizing machine (JUPITER) and then wrapped on a warping machine also from (JUPITER)

6. PICANOL: The Wrapped yarns are then woven on a Rapier Loom or projectile loom using weaving machines for that we have.

7. GOLLER: Goller from Germany (part of Fong’s Group) is offering innovative technical solutions, which can be tailor made to all requirements in the field of woven Denim continuous wet processing such as Desizing & Washed off, Mercerizing, Over-Dyeing.

Besides, with its operationally efficient and environmentally friendly features, GOLLER offers the highest achievable production safety, sound reliability and flexibility and constant premium quality.

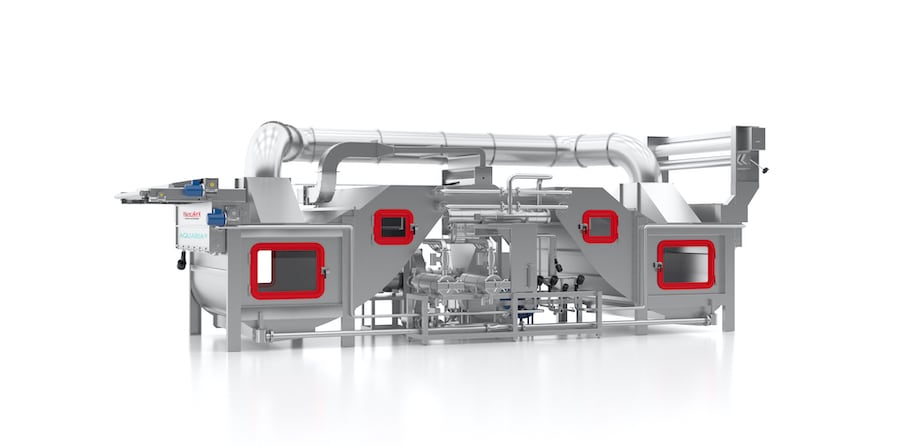

8. Biancalani: For special wet treatments of denim or any type of fabrics BIANCALANI from Prato, Italy, is offering the AQUARIA®️ open-width continuous washing range, a unique patented machine which matches a very long dwelling time with intense mechanical action, ideal for giving to denim fabrics a special look (such as enzyme washing or pumice treatments) and to relax it and increase its dimensional stability with simpler hot washing processes, all in open width.

After the washing process, BIANCALANI can also provide its AIRO®️ 24 continuous open-width airflow dryer which will efficiently dry and relax, with intense and controlled mechanical action, all types of the stretch fabric allowing to reach optimal levels of stability and elasticity together with an increased softness.

9. HAIDA: The woven product is sanforized ( It is a method of stretching, shrinking and fixing the woven cloth in both length and width before cutting and producing, to reduce the shrinkage which would otherwise occur after washing) for that we use a stenter or RAM as people sometimes call ( we have a supplier from China called HAIDA they produce good stenters with good price).

10. EAS: EAS is a company from Spain for (Automation· Color kitchen· Software) Software, dosing and dispensing systems and you and your readers are welcome to check up their videos on YouTube.

and they have a good system for Denim manufacturers called TECNO DENIM TecnoDenim. In general, it is a solution for the automation of the indigo dyeing process completely.

11. ZSK: ZSK is among the most innovative company in GERMANY. ZSK Embroidery machines for your highest design and production demands and have all these advantages:

a) The ZSK embroidery machines are very robust and perfect for use on jeans (denim) due to the height-adjustable presser button (standard, not option)

b) The ZSK embroidery machines are network-compatible and can therefore be seamlessly integrated into the automated production process.

c) The ZSK embroidery machines are very flexible and can be retrofitted with special units for fashion, such as sequins, beads, HAC, cords or drills at any time and without problems.

12.TAS: TAS company for printing is an Australian company. Printing on Denim is fairly straightforward using plastisol, pretty much the same as printing any other types of garments.

Some materials require special inks but the printing method is the same as any other garment on an automatic screen printing machine. Depending on how detailed or fine the image is needed to look like, it will be needed to determine what screen mesh count will be used . On some of the white inks, the ink can be quite thick and hard to push through high count meshed screens.

Additives are used in general screen printing practices to thin out some of the thick inks that are around, so it all depends on what inks will be used and what mesh count to use to achieve a crisp and clear image on the denim

13 . Xetma Vollenweider a German company

Besides a nice visual aspect, an attractive hand-feel of the fabric surface becomes more and more important for fashionable Denim products. With its Emerizing and Brush-Sueding machines, the German-Swiss company Xetma Vollenweider enables Denim manufacturers to create a nice Soft Touch on the fabric surface.

Particularly the so called Rose-Petal Touch created by the X-TREME XEB combined Emerizing+Brush-Sueding machine is unique in both, softness and density. Thanks to the pure mechanical processing the technologies offered by Xetma Vollenweider are sustainable and the finishing effects created are permanent.

What are the latest technologies and innovations in denim and jean machinery?

Well, nobody can say for certain there is always something new for example the last thing I heard about was bleaching and washing by OZONE and for some specialist that may be considered old but if I am going recommend something I would recommend the TECNO DENIM system from EAS, it is a very advanced and practical system for denim manufacturers, because it can give accurate operational data for higher management in real-time and as you know knowledge is power with this data a lot of manufactures can detect problems and evaluate their progress accurately and thus make a real and good plan to overcome their problems or make an expansion as you will see in the video it might be considered a semi Artificial intelligence system though it won’t solve problems on its own or make new systems or plans or even learn that on its own but it can give you eyes to see the world differently through the data it provides.

Why using latest technology and up to date machinery is important for Denim makers and jean cloth manufacturers?

Most of Denim manufacturers may not agree on this but you have to understand their point of view, most of the machines they buy are extremely massive and thus it is expensive and also the lifetime of such machines is quite long so in order to persuade them to make another huge investment is quite difficult but we also try to recommend and clarify the advantages of using the latest technologies especially the ones that can save water, energy and time and eco-friendly this is the most important point like OZONE technology it was theorized it can save water and chemicals up to 90%.

As a textile machinery expert, how do you evaluate Denim Sector in Egypt in term of technology and machinery?

Most of the denim producers or manufacturers in EGYPT are not very old, so most of their machines are new and their machines are up to date and they always take care of their machines with good maintenance stuff and good workers.

Egyptian Denim producers have a good export number to the international market and brands, how do you evaluate future of this sector in Egypt?

In long term it is going to be very wonderful and bright even though it might not seem like that now due to the effects of COVID-19 but the Egyptian government are making a lot of investments in a lot of sectors especially in textile, I believe you should know they are planning to setup the largest denim manufacturing plant in the entire middle east and Africa in Dumyat it is not official yet but they are planning and making studies for it and we know this because of our line of work and our connection with them and that is not the only thing they are doing building and improving infrastructure will have its effect it may not be obvious now but it will show its effect and also improving investment laws have its effect, it is up to the investors to read the future carefully and seize the moment and make their calculations.

After war started in Syria many textile and denim manufacturers immigrate to Egypt and continue the production, also some Turkish companies enter to Egypt for denim production, why Egypt is attractive for these companies?

Some Syrians have been in EGYPT for a long time even before the war so Egypt might be considered their 2nd country and they didn’t take along time to adapt or familiarize themselves with the Egyptian market.

As for the and Turkish companies, Egypt has a lot of free zones and most of them are setup in these zones (an area within which goods may be received and stored without payment of duty)

Free Zone Benefits and Costs

• 100% foreign ownership.

• 100% repatriation of capital and profits.

• 100% import and export tax exemption.

• 100% exemption from income and corporate taxes.