Interview with Arantxa Mur / Marketing & Comms Department at PICVISA

PICVISA is eager to participate at ITMA Milano 2023, where we’ll be demonstrating our innovative ECOSORT TEXTILE system, an automatic garments sorting solution that utilizes NIR (Near-Infrared) and AI technology. Alongside this, we’ll also be showcasing our clippings quality control solution, a technology that brings increased accuracy and efficiency to textile recycling and upcycling processes.

Please let us know about your Participation at ITMA Milano 2023 and Range of products and properties

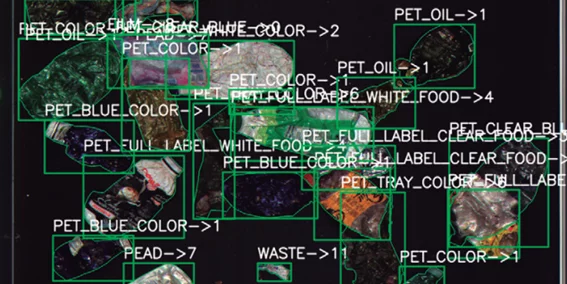

PICVISA’s primary product line for the textile industry is our ECOSORT TEXTILE system. This machine offers automatic sorting by fiber and color for textile reuse, recycling, upcycling, and downcycling. Leveraging a database fed by over 40,000 images for textile recognition, this machine exemplifies precision and efficiency in textile sorting.

The continuous development and expansion of our classification database has established PICVISA as a trusted leader in textile sorting technology.

Sustainability and Recycling with PICVISA

Our commitment to sustainability revolves around preventing textile from ending up in landfills, and we achieve this with our automatic sorting solution. With accurate sorting being a pivotal process in textile recycling, our machinery enables the recovery of both post-consumer textiles and post-industrial clippings. This results in minimized textile waste, fostering an environmentally-friendly textile industry.

Reducing Production Costs

At PICVISA, we believe that automating the sorting process is key to reducing operational costs for textile factories. Our machinery not only optimizes material recovery but also mitigates waste generation, leading to significant cost savings and more efficient use of resources.

Evaluation of the Spanish Textile Machinery Manufacturing Sector

The Spanish textile machinery manufacturing sector has a rich and diverse heritage that has evolved over centuries, positioning it as one of the key players in the European Union. The industry has historically excelled in manufacturing a range of products from spinning, weaving and finishing equipment to the increasingly important sector of recycling and waste management machinery.

Today, the sector has recognized the potential and the need for advanced technology, and it is heavily investing in research and development activities to bring about innovative solutions. One of the main driving forces of this innovation is the transition towards more sustainable manufacturing processes, and a circular economy model that minimizes waste and makes efficient use of resources.

Furthermore, Spanish manufacturers have consistently shown resilience in the face of economic uncertainty, continuously adapting to new market demands, regulatory changes, and evolving consumer preferences. For example, they have managed to successfully shift from traditional manufacturing methods towards more automated, digital, and environmentally friendly processes.

The Spanish textile machinery manufacturing sector also benefits from a collaborative ecosystem that includes a strong network of suppliers, academic institutions, research centers, and government agencies all working together to promote growth and innovation in the industry. This collaborative spirit, combined with a commitment to quality and technological excellence, helps ensure Spain’s continued leadership in textile machinery manufacturing on a global scale.

Digitalization in Textile Recycling: A key focus for PICVISA

This process involves integrating advanced digital technologies into our machinery, leading to more efficient and transparent recycling processes. For instance, our machinery is equipped with advanced sensors, AI technology, and data analytics capabilities, which not only improves the efficiency of the sorting process but also provides valuable data insights that can be used to optimize operations.

One of the most notable features of our digitalization effort is the real-time data platform provided by our equipment. This platform allows our customers to monitor the volume and composition of textiles being processed at any given time. It provides valuable information such as the quantity and type of materials being processed, the efficiency of the sorting process, and the amount of waste being generated. This data is essential for process optimization, improving efficiency, reducing waste, and ultimately improving the bottom line.

Additionally, this platform enhances traceability throughout the recycling process. Customers can trace the lifecycle of a textile product from its entry into the recycling process to its final destination, whether that’s reuse, upcycling, or downcycling. This traceability is particularly important in meeting regulatory requirements and demonstrating a commitment to sustainability. Our first customer, Coleo, successfully implemented this full traceability process, significantly increasing their operational efficiency and transparency.

By integrating digitalization in textile recycling, PICVISA is providing not just machinery but a comprehensive solution that addresses the needs of the modern, sustainable textile industry. We believe that the combination of advanced technology and valuable data insights can empower manufacturers to make more informed decisions, optimize their operations, and make a meaningful contribution to a sustainable future.

Importance of Textile Recycling

Textile recycling has become increasingly important due to a variety of social, environmental, and regulatory factors. For one, consumer awareness about the environmental impact of textile waste has grown significantly. People are increasingly looking for sustainable products and are more conscious of the lifecycle of the items they purchase.

As a result, manufacturers are under pressure to adopt sustainable practices, including recycling and upcycling of textiles.

Another driver is the improvement in technology. Advances in sorting technology, such as those provided by PICVISA’s ECOSORT TEXTILE system, enable more efficient recycling processes, making it a viable and profitable option for manufacturers.

Moreover, new developments like chemical recycling offer the possibility of breaking down textiles into their raw materials, opening up new avenues for recycling.

Then, there is the legislative aspect. The European Union, for instance, is introducing regulations encouraging recycling and penalizing waste. The Extended Producer Responsibility (EPR) regulation, for example, encourages manufacturers to take responsibility for the disposal of their products, thus promoting recycling.

Finally, the growing recognition of the need for a circular economy is also pushing textile recycling to the forefront. In a circular economy, the aim is to keep materials in use for as long as possible, extracting the maximum value from them while in use, and then recovering and regenerating products and materials at the end of their service life. Recycling, including textile recycling, is a crucial component of this model.

Standards and Certificates

PICVISA abides by all relevant local and international standards in the design and manufacturing of our machinery, reinforcing our commitment to safety, quality, and environmental responsibility. PICVISA has different technical certifications. This is thanks to an integrated, certified and consolidated management system.

The system is based on international standards ISO 9001 for quality management, ISO 14001 for environmental management and OHSAS 18001 for occupational risk prevention.

Additional Information

One of our successful collaborations was with Coleo Recycling in A Coruña. Coleo integrated our ECOSORT TEXTILE system, significantly improving their textile recycling processes and reducing their environmental impact. They firmly believe they can change the textile sector to achieve a more equitable industry, facing and solving the challenges posed by textile waste through teamwork, transparency, and traceability.

Each phase of the Coleo process has its own local and scalable ecosystem. Together, they keep the planet spinning: from garment collection to their sorting and recycling in inclusive and innovative workplaces where waste is transformed into new raw materials.

Fabric that will be part of the design and manufacture of brand-new garments, with the fascinating (im)perfection of recycled colours and design. This successful case study demonstrates the real-world application and impact of PICVISA’s technology and highlights our commitment to fostering sustainable and efficient operations in the EMEA region.