Interview with Mr. Julian Pineyro, Director of the Textile and Denim Division at Masca ID

KTJ: First of all, please tell us more about Macsa ID’s company history and its success story in the textile and fashion sector.

JP: Macsa ID is one of the market leaders of laser technology company worldwide, with an excellent reputation for delivering manufacturing innovative solutions for many industries like food and beverage, pharmaceutical, automotive, etc. With a history of over 100 years in the marking and coding industry, we have always been at the forefront of cutting-edge technology, and our expertise in textile laser technology is no exception.

One of the most important achievements for Macsa ID was developing the world’s first-ever textile laser machine and software in 1999. This is a significant milestone that reflects the company’s commitment to innovation and problem-solving while making the key contribution of providing sustainable technology which drastically reduces the use of chemicals and water consumption during the denim finishing processes.

Today, our Lasertex equipment is the fastest and most efficient in the textile industry thanks to our state-of-the-art, high-end range. With a worldwide presence in over 90 countries, Macsa id works with a network of distributors in each country in order to provide the best service to our clients wherever they may be.

Macsa id’s headquarters and its production plants are in Barcelona (Spain), the UK, China, and India and we also have local offices in Malaysia, South Africa, and Portugal.

Macsa ID Services

KTJ: Tell us more about Macsa ID Services and how you can help apparel and garment manufacturer in their sustainability and digitalization processes.

JP: Macsa is the best partner for high-end laser machines with a complete range to fulfill any customer production need, from a fixed table machine, and a conveyor belt machine with one or two laser tubes to a very sophisticated full mechanical mannequin with zero maintenance.

We also offer in-house developed hardware, software and services solutions, to help customers to attain their business objectives by achieving significant improvements in quality, safety and performance.

There is no doubt that the digitalization process is essential to modernize the Textile Industry and Macsa has different tools to support our customers in their journey. Firstly, Marca 6.0 is a Design software platform that creates and adjusts any type of finishing design and obtains best-in-class results.

Secondly, Jeanethics® 4.0 is a cloud software program that is focused on monitoring any type of production finishing machinery and tracking their maintenance information in order to optimize and improve productivity. In addition to these programs, all our Laser machines have troubleshooting tools controlled by our Remote Technical service which can diagnose and fix issues instantly.

KTJ: What are the unique features of Jeanethics® 4.0, Marca® 6.0 software and Integra serialization?

JP: The new Jeanethics®4.0 cloud software platform allows brand owners, certification agencies and manufacturers of today to be fully aware of their sustainability performance by monitoring it constantly.

Users will be able to track, control and report key data about the production, machinery consumption (water consumption, power, etc), and maintenance control, in real-time and through the data provided by the production equipment automatically.

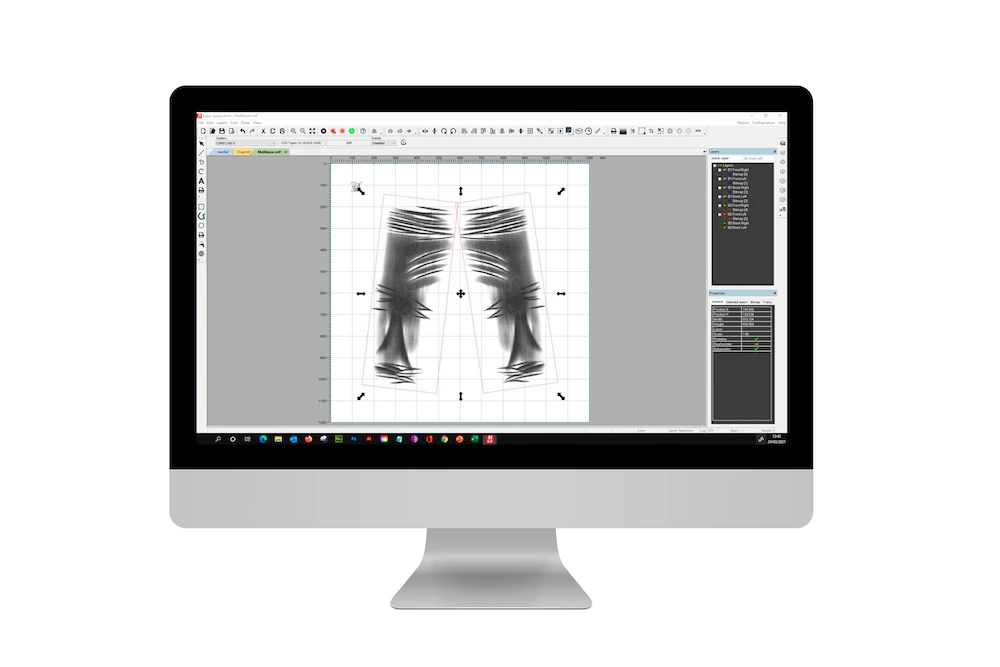

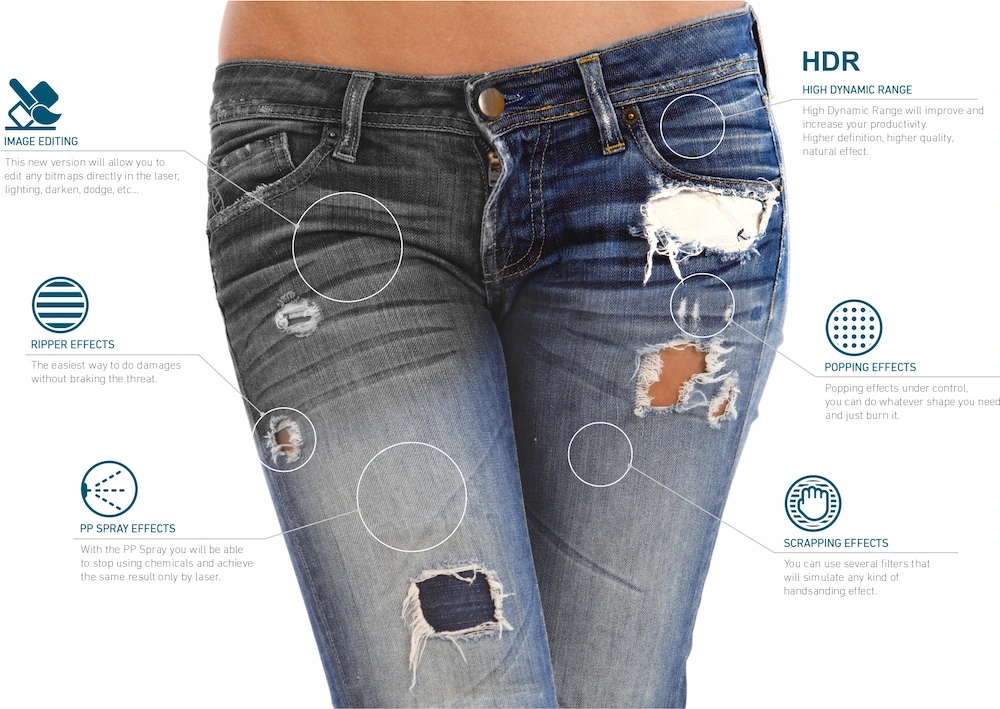

As already mentioned, Lasertex systems work with the MARCA® 6.0 software, developed by Macsa id. This is a fully integrated tool where any designer will be able to apply different kinds of effects, filters, specific textures, etc to any type of garment before going into production.

Our MARCA® 6.0 software has been designed taking into account all those textile application needs. This new software will open our customers’ businesses to a new world of possibilities, increasing productivity and helping designers to increase efficiency.

There is no question that it is an easy and powerful tool and with the Laser Test Fabric, you will be shown how the denim reacts under each laser effect. With just two samples, you will be able to know the exact parameters needed to run production. The High Dynamic Range will improve and increase your productivity while giving higher definition, improved quality and natural effects.

Finally, Integra serialization is a software traceability solution that can make the unmistakable distinction between an original product and a counterfeit. Unique indelible codes (QR, barcodes and serial numbers) can be printed which guarantees the product’s origin while ensuring supply chain traceability at the same time. In addition to ensuring this product authentication, applications can also provide the means to engage directly with your end customer.

KTJ: What are the unique features and specifications of a Masca ID textile laser finishing line?

JP: Macsa ID offers a range of unique features and specifications in its textile laser finishing line that sets it apart from other solutions. Some of the notable features and specifications include the following:

• Eco-Friendly and Sustainable: a Macsa ID textile laser finishing line is designed with a focus on sustainability. By utilizing laser technology, the need for hazardous chemicals is eliminated, water consumption is reduced, and waste generation is minimized. This makes it an environmentally friendly choice for textile finishing, by supporting green manufacturing practices.

• High Precision and Versatility: The Macsa ID textile laser finishing line provides exceptional precision and versatility in fabric processing by offering intricate and detailed designs, precise distressing, fading, and cutting. All these options enable manufacturers to achieve a wide range of creative effects on different types of materials.

• Advanced Software Control: Marca 6.0 is an advanced design software that allows precise control and customization of laser parameters. This enables manufacturers to create complex patterns, designs, and effects with ease, ensuring consistency and quality across production batches.

• Fast Processing Speed: Our solutions feature fast processing speed, enabling efficient and high-volume production. This helps manufacturers meet demanding production timelines while maintaining exceptional quality standards.

• Reliability and Durability: Macsa ID is known for its robust, durable and high-quality equipment. The textile laser finishing line is built to withstand demanding production environments, ensuring reliable and consistent performance over time.

KTJ: Sustainability is an essential subject for textile manufacturers all around the world. How can Macsa ID help manufacturers design a better sustainability roadmap?

JP: Our Lasertex series equipment has been key to achieving traditional finishes and at the same time reducing the ecological footprint on the way. Laser technology avoids the need for sandblasting, PP spraying systems or manual hand-sanding while increasing production capacity substantially. Moreover, the precision, accuracy and reproducibility standards provided by laser systems ensure first-time quality for all your production runs.

With our Lasertex range, the best-in-class cost of ownership is guaranteed with no need for expensive consumables and with only minimal maintenance required. A laser is not only environmentally friendly, but it also protects those direct workers responsible for the finishing process by eliminating the use of hazardous chemicals used in traditional processes, as well as removing the need for manual finishing processes.

Laser technology works as a thermal energy that is able to remove the indigo from its original fabric by a sublimation effect. The remaining smoke is removed by an extremely powerful smoke extractor. With this technology, one operator will be able to produce more than 200 pieces/hour.

KTJ: How can Macsa Textile Laser support Denim manufacturers comply with international standards and certifications by using Laser technology?

JP: As mentioned before, Laser is a green technology that helps to avoid the use of dangerous chemicals, reduces water consumption and eliminates the need to apply manual processes. Additionally, Macsa Textile Laser enables manufacturers to achieve consistency and repeatability in their production processes, ensuring uniform quality across denim products.

This consistency is crucial for meeting the stringent requirements of international standards and certifications, as it guarantees that each garment adheres to the specified criteria.

Overall, by adopting Macsa Textile Laser, Denim manufacturers can demonstrate their commitment to sustainable practices and ethical production, which in turn enhances their ability to meet the demands of international standards and certifications.

KTJ: Please let us know about Macsa ID’s participation at ITMA Milano 2023. Do you have any new technology to exhibit in ITMA for the first time?

JP: ITMA Milano is an excellent opportunity for visitors to learn more about Macsa ID’s innovative laser technology solutions, not only our first-in-class software that we have already mentioned but also our New Lasertex Unno Agile, Futura 1200, and Lasertex Retail.

Lasertex Unno Agile is a robust and compact fixed-table laser system designed specifically for higher production runs and with two working modes. The system offers unparalleled precision with a high-resolution 3D Scanner, which allows manufacturers to create unique designs on denim quickly and easily.

The Lasertex Unno Agile’s size means it can be set up in very reduced spaces, equipped with a projector to enable easy and accurate garment placement. Its state-of-the-art features result in high productivity, flexibility, and profitability.

Lasertex Futura 1200 is a double Laser tube system (600wx2) with a high-speed marking time, which enables high productivity by operating two belts simultaneously with high-speed marking. It includes a closed cabin marking area to ensure safety. The system offers unparalleled precision by using a high-resolution 3D Scanner, allowing manufacturers to create innovative designs.

Lasertex Retail is a safe and attractive Retail Laser equipment that allows brands and retailers to transform any garment into a unique personalized product for their customers directly on the shop floor. It is a stand-alone plug-and-play unit with a very “Cool&Sexy” design.

Needless to say, if you visit us during the show, you can ask us more about all the software options we have to offer such as, software platforms and developments of the latest version of the Jeanethics® 4.0, Marca 6.0, and Integra serialization.

KTJ: Finally, can you add any other information that you think may be interesting for our readers in the EMEA region?

JP: We will be very glad to meet you at our booth at ITMA MILAN (HALL18-C201). You will be able to see the Macsa Textile new range and discover how we can support you to transform your production into a sustainable model. Our team will be delighted to offer guidance and advice on how our laser technology solutions can streamline your manufacturing processes and boost your productivity.