In the ever-evolving landscape of textile machinery, sustainability has become a paramount concern. As industries strive to minimize their environmental footprint, Tecnorama, a pioneering player in the field, has made a remarkable stride towards a greener future with its Dos&Dye® cutting-edge laboratory dispensing and dyeing system.

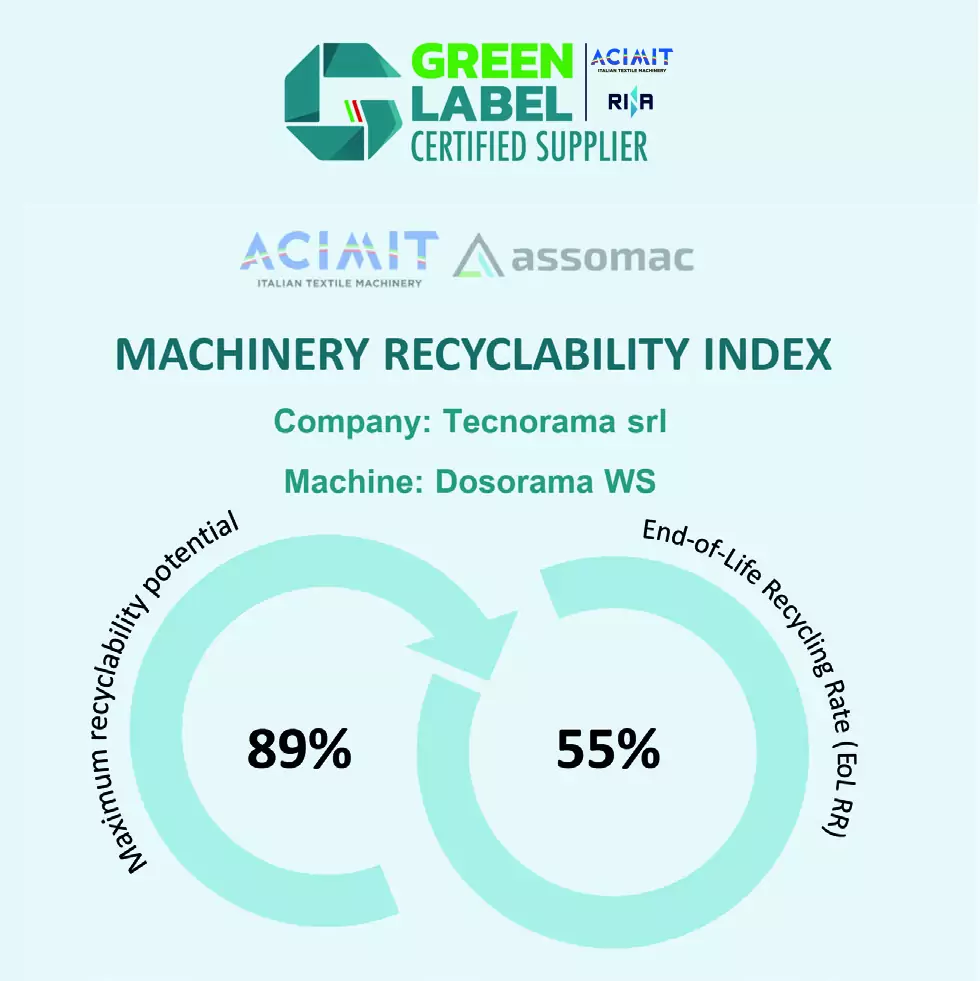

Dosorama WS, the most performing dispensing machine of Tecnorama, totally integrated into the Dos&Dye® System, has recently earned a noteworthy achievement – a high Recyclability Index as part of the “Green Label” certification promoted by ACIMIT, the Italian Association of Textile Machinery Manufacturers. The certification places a significant emphasis on sustainable practices, encouraging manufacturers to adopt eco-friendly technologies and processes.

The recyclability index, a key component of the “Green Label” certification, signifies the machine’s commitment to environmental stewardship. It is a testament to Tecnorama’s dedication to advancing sustainable solutions in the textile machinery sector. This certification acts as a guide for manufacturers and consumers alike, identifying machinery that meets environmental standards as Carbon Footprint and Recyclability Index.

The Dosorama WS’s design, materials, and manufacturing processes align with the principles laid out by ACIMIT, has excelled in the certification process both for Maximum recyclability potential expressing the possibility of separating a material from the mixed waste stream and for End-of-Life Recycling Rate (EoL RR), an index that takes in account the share of waste material that is collected, pre-treated, recycled and fed back into the production cycle.

The achieving of Recyclability Index is yet another recognition that adds to the well-known green performances of the patented Dos&Dye® laboratory system. Dos&Dye® not only streamlines the recipe replication process for production dyeing machines but also boasts remarkable “green” features that contribute to a more eco-friendly textile industry.

Automated Precision for Sustainability

The Dos&Dye® system eliminates the guesswork and minimizes trial-and-error attempts in achieving precise dye recipes for replication in production dyeing machines. Its automatic dispensing capabilities usher in a new era of efficiency, reducing the need for numerous attempts to obtain the exact formula. This not only ensures accuracy but also significantly cuts down on resource consumption.

With the adoption of Tecnorama’s Dos&Dye® system, textile manufacturers benefit from a range of environmentally friendly advantages in production:

1. Water Consumption Reduction: The automated precision of the Dos&Dye® system ensures optimal dyeing with minimal water usage. By precisely dispensing the required amounts and avoiding unnecessary attempts, water waste is curtailed, contributing to water conservation efforts.

2. Energy Consumption Reduction: The system’s automation not only enhances accuracy but also reduces energy consumption during the dyeing process. This eco-conscious approach aligns with the industry’s commitment to minimizing environmental impact.

3. Time Optimization: The streamlined dispensing process not only saves time but also maximizes efficiency. This not only benefits manufacturers by accelerating the production workflow but also contributes to overall operational sustainability.

4. Increased Productivity and Cost Savings: The combined impact of reduced water and energy consumption, coupled with time optimization, translates into increased productivity. This boost in efficiency not only enhances production output but also results in economic savings for manufacturers.

Tecnorama’s Dos&Dye® system stands as a testament to the company’s dedication to both precision and sustainability. By seamlessly integrating automation with eco-friendly practices, Tecnorama is not only simplifying laboratory processes but also actively contributing to a greener and more responsible future for the textile industry. Manufacturers embracing this innovative system can improve operational efficiency and also enjoy a significant reduction in their environmental footprint.