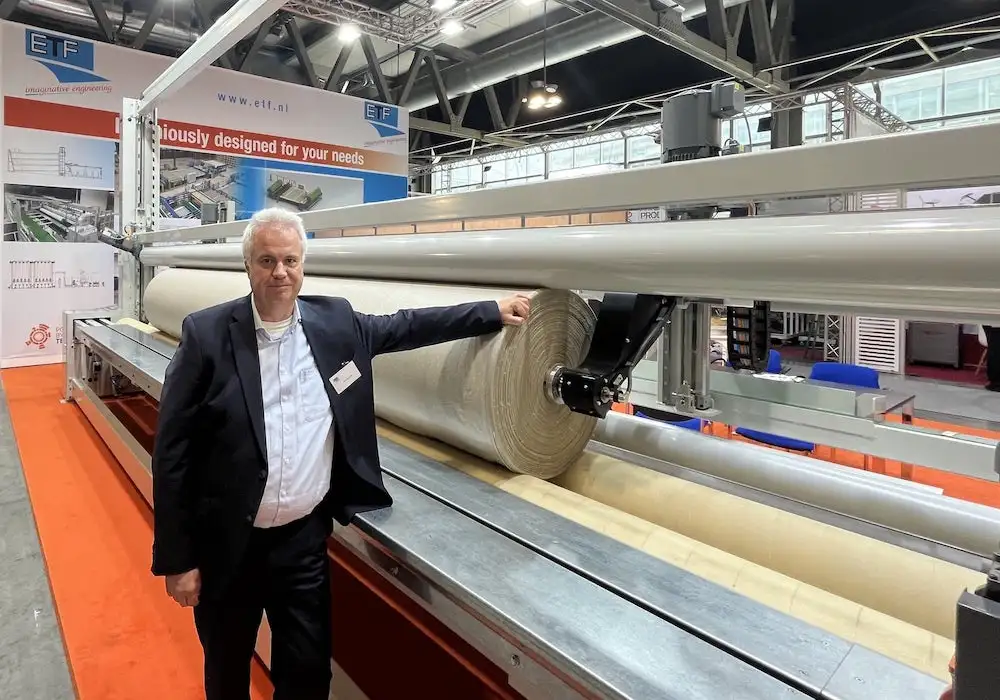

Interview with Mr. Jos Sloesen, Director of Sales and Marketing at ETF Machinefabriek B.V.

- Tell us to know more about ETF company:

ETF Machinefabriek designs and manufactures machines for the inspection, cutting, rolling, packaging, transporting and sorting of a wide range of different floor coverings, artificial grass and nonwovens. Our machines are suitable for a multitude of utilisations and are designed to offer you an all-in-one solution.

Our machines can also include smart customized process automation to reduce the number of operators to an absolute minimum or to extend the working range to the max.

Versatile Rolling Machine ETF sold To Mattex Saudi Arabia

One of our latest innovations and machines that we exhibit here in ITMA 2023 Milan is rolling machine with a 5,4 meters width that is usable the nonwoven industry, floor covering and artificial grass and basically all the available rolling techniques and specifications are include this machine, like main roller, pressure roller, and center drive.

- What do you think about the Middle East and African flooring Market?

Middle East and Africa is a very important region for us. During the ITMA in Milano, we met many interested visitors from Turkey, Saudi Arabia, the Middle East, and Africa, and they were really serious customers and were open to new investments in the region.

We sold the First New Versatile Rolling Machine exhibited in our booth to a large manufacturer in the Middle East.

They have an existing line and they exchange their current roller by our rolling unit very soon, this is an example that how the MEA region is important for our business. Also in Turkey, as the world’s main carpet production hub, we have many lines and working machines.

- How do you Evaluate FloorCovering Machinery Manufacturing in the Netherlands

There is a strong machinery sector in the Netherlands that manufacture high-tech products for global markets. The Netherlands is a small country but we have many high-quality universities and research and development centers and very well educated engineers.

In last decade many companies specially in second or third world countries start to make machinery and trying to get a piece of the cake, we can say that they are successful in some sectors but in many sectors that need high technology, know-how, innovation and high tech engineering they are not successful and exactly there is the point that European machinery manufacturers can show their ability and potentials.

We as a European machinery manufacturer should invest more in research and development, innovation and high-tech technologies and this is our main advantage to be always a few steps ahead of competitors.

In the carpet sector, there are many famous and well-known brands in the Netherlands that produce high-quality and sustainable flooring worldwide.

- Please explain more about your latest innovations that exhibit in ITMA

ETF is present at ITMA, The world’s largest exhibition for textile equipment, for the 13th time

At the ITMA exhibition, ETF will introduce and exhibit its new rolling machine type M 5728, which can roll a broad range of materials. ETF engineers have designed this machine in a modular way so that it can be equipped with various options for adapting to the material to be rolled and your requirements. Even switching between different options without needing to (partly) rebuild the machine is possible.

New at ITMA: Our Versatile Rolling Machine

It is a nonwoven rolling machine with all possible options for rolling straight and tightly wound rolls, but the technology can also be applied to, for example, carpet and artificial grass.

This versatile rolling machine is equipped with many innovative features, such as center drives and a controlled push roller. These functions guarantee the production of very tight rolls, which is essential for clients when rolling items such as non-woven materials or artificial grass. Once the material has been fixed to the core, either automatically by glue or by staples, for example, a driven head moves into the core at both sides and then pneumatically expands to fix the core in place.

An intelligent operating system controls the speed of the individual main rollers, the expanded heads and the pressure of the push roller. The pre-set settings of all these items can be chosen via a menu for either the roll-start and/or the further rolling process, to achieve the optimal settings for the different qualities of materials to run on this machine.

The model of the versatile rolling machine on exhibit is also equipped with a double-driven cross-cutter. Thanks to the direct driving of both the upper and top circular knife, a broad range of material thicknesses can be cut without holding or damaging the material. Furthermore, a layer of glue can be applied on the starting edge of the new roll during crosscutting. By rolling the material somewhat in the reverse direction, it will be attached to the core automatically, after which rolling the next roll can be started without operator intervention.

Other options for this new rolling machine include:

- easily adjustable main rollers, for working with a large variety of tubes and/or roll diameters;

- an automatic tube dispenser (not shown) for starting rolling fully automatically without operator intervention (in combination with the glue system);

- an optical length-measuring system to measure with an accuracy of more than 0.15%.

During the ITMA exhibition, we will be happy to inform you about all the features and benefits of this versatile rolling machine, and how it can enhance your production process. Of course, we will also gladly inform you at our booth as well about all other ETF machine concepts, related to inspection, rolling, wrapping, roll transport and sorting.

For more information about ETF machinery and services DOWNLOAD BROCHURE