Pioneer of digital printing techniques on textiles, Epson unveiled its new Monna Lisa printers at ITMA 2023, demonstrating the latest Epson innovations for a constantly evolving digital textile market.

The latest innovations in the Monna Lisa series presented at ITMA 2023 feature Epson’s PrecisionCore Technology to offer complete and flexible solutions meeting all textile market needs. At ITMA 2023, Epson showcased its new, revolutionary Monna Lisa ML-16000/HY and Monna Lisa ML-24000, as well the REACID configuration integrated for the first time in Monna Lisa ML-8000 and Monna Lisa ML-32000 in its 340 cm width version.

“Epson is constantly focused on renewing and expanding its range of solutions for textile printing and offering its customers the opportunity to meet the needs of an increasingly demanding and competitive market seeking the experimentation of new approaches, from shorter processes to the use of new fibres”, says Paolo Crespi, Commercial Director at Epson Como Printing Technologies. “Thanks to our extended Monna Lisa series, we strongly want to highlight how the transition to increasingly sustainable textile production processes can be implemented through highly flexible solutions”.

Monna Lisa ML-16000/HY – Special printing effects that elevate production to a new level

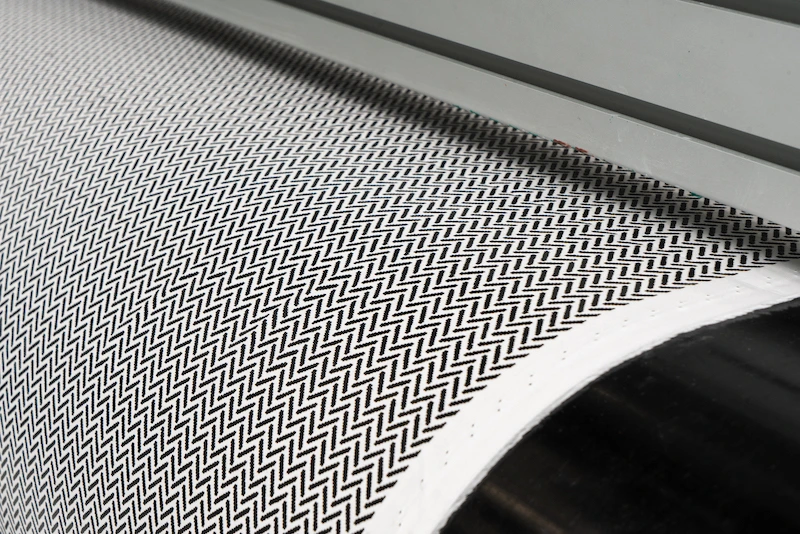

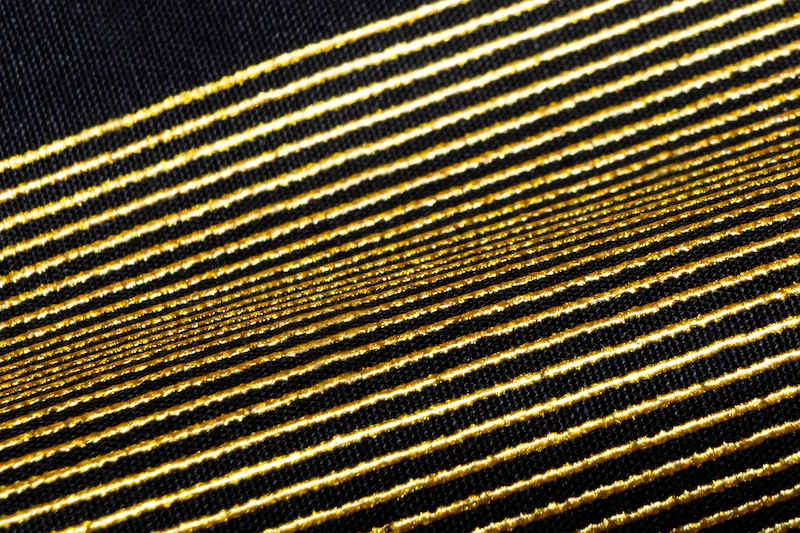

The revolutionary Monna Lisa ML-16000/HY is the ideal printer for companies that need to optimise the production of complex prints and offer the market more creativity. It can uniquely digitally create any type of the most sophisticated special effects for modern printed fabrics with gold, silver, and glossy tints, ranging from glossy lacquer through to gold and silver metal and opaque white.

Monna Lisa ML-24000 – Unprecedented flexibility and widest colour range in the series

Concept of flexibility and efficiency is raised to the next level thanks to the wide range of available colours, the reduction in the downtime required to change inks and the possibility of producing certified printed fabrics without changing the type of inks in the machine.

The first to be equipped with 24 Epson PrecisionCore printheads and 12 colours, Monna Lisa ML-24000 can print on all types of fabrics from natural, artificial, and synthetic fabrics through to the most innovative vegetable fibres. Thanks to the wide range of inks supported, companies can finally obtain any specific required certifications (such as GOTS or OEKO-TEX) very quickly and just by relying on one single machine.

Monna Lisa ML-8000 REACID configuration – The most flexible solution to cover all fibres

Monna Lisa ML-8000 is the first printer in the series to be designed with the REACID configuration, which is an absolute novelty in the Monna Lisa landscape and will soon be available on all other printers in the series. This configuration reinforces Monna Lisa’s ability to adapt to a wide range of printing requirements, providing greater flexibility of use.

Monna Lisa ML-32000 – Width 340 cm – More efficient printing process for the home textile sector

Monna Lisa ML-32000 combines Epson’s high-tech digital technology with unprecedented versatility. Its width of 340 cm allows it to print wide size of woven fabrics (bed sheets, curtains, etc…) and in addition, two pieces of fabric can be printed simultaneously, thus increasing productivity and reducing energy and resource consumption. Thanks to its increased dimensions, Monna Lisa ML-32000 is now also a player in the home textile sector.

Endless range of possibilities with Epson’s SureColor series featuring textile applications

At its stand, Epson displays its SureColor series including its DTG high-productivity printer Epson SureColor SC-F3000, which offers reliability, flexibility and high-quality printing on finished textile products; Epson SureColor SC-F10000H, allowing companies to obtain highest quality results over a wide range of applications, especially for fashion and interior design with cyan and light magenta; and Epson SureColor SC-S80600L, which is equipped with a 10-colour ink set for high-quality printing on faux leather for fashion, accessories, and interior decoration.

Epson’s technology as told by fashion designs

On Epson’s stand it is possible to see and touch some examples of fashion creations by some of the most renowned Far Eastern fashion designers, who depend on Epson’s high-quality printing technology for their fashion works. Designers exhibited are: Korean top fashion designer Lie Sang Bong, fashion designer and art director Aguri Sagimori and Japanese fashion designer based in Paris, Yuima Nakazato.

In particular, Nakazato’s creative works come directly from Paris Fashion Week Haute Couture, where some of his creations were based on the new, more sustainable and potentially industry-transforming textile production concept called Dry Fibre Technology (DFT). Epson’s Dry Fibre Technology concept, which is already used commercially to recycle office paper and which requires virtually no water, could be adapted to produce printable non-woven fabric from used garments.

Kyoto University fashion designers’ and Japanese Bunka Fashion College students’ fashion projects are also showcased at Epson’s booth.