The discovery of artificial fibers has marked the beginning of a whole new period in the textile industry. The thing is, there are so many qualities, very different from one another, and this is the current focus of textile experts looking for specific ways of treating each of them and their countless, interesting, valuable combinations. That is what Biancalani Textile Machinery has been studying and working on in the last years.

The world of synthetic fibers may be divided in two hemispheres: the one inhabited by artificial fibers regenerated from natural ones, i.e. viscose, tencel, modal, cupro; the other featuring fibers made from synthetic fibers made of polymers, i.e. nylon, polyamide, polyester. As already mentioned, the two groups must be processed in sometimes completely different ways as the desired results may vary.

For a certain period, regenerated artificial fibers have somehow replaced regenerated fibers, thanks to lower production costs. However, to date, the last are back in the textile game and are considered somehow noble and niche. Much depends on the finishing process, that has to ensure specific features.

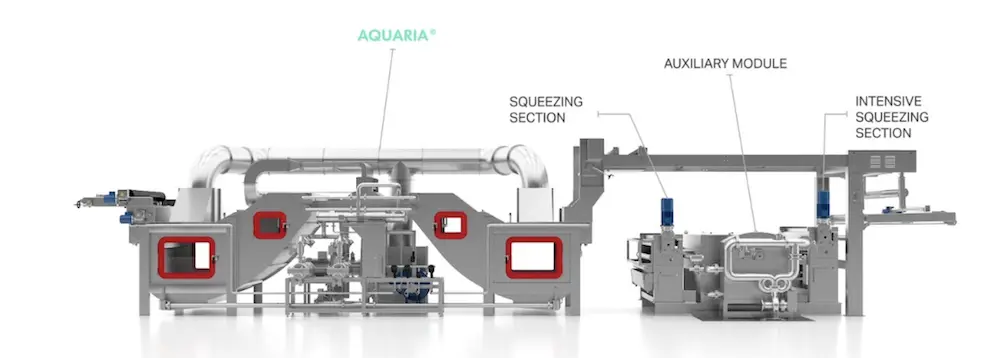

First of all, it has to be as environmentally friendly as possible and second, processed fibers must be top-quality and aesthetically precious. Eventually, regenerated artificial fibers should be the closest to natural fibers. In this case, AQUARIA® by Biancalani is definitely the one machine that ensures an incredible number of complex finishing options, exactly what is needed to deal with the different characteristics of fibers synthetized in as many different ways and thus with inevitably various applications.

As per the group of synthetic polymers, the discovery of polyester in the first half of the 20th century – it was an American giant in chemicals that bought the rights from a group of English scientists – meant a real boom in the industry. Soon enough, it was clear that combining polyester with other fibers could make the difference – for example, polyester can enrich cotton with specific characteristics such as strength and mechanical ones such as waterproofness. Definitely, it needs to be ennobled by specific machineries, while processing costs shall remain competitive. Biancalani suggests not only the high-performing, worth-discovering AQUARIA®, but also AIRO®24 with its AIRO® HAND effect.

In fact, for some specific processes, textile machineries by Biancalani are unique because they feature continuous open-width processes. Concretely, and especially if compared to discontinuous, in rope processing, it means higher performances – i.e. producing large quantities at a fast pace – lower water consumption, lower risk of fabric flaws. And, above all, it means fine-tune the process with the fibers characteristics, thus being able to produce top-performing fabrics at competitive costs, like the ones employed by the automotive industry – but not only.

The low risk of fabric flaws is a must in the fashion industry, as using specific processes makes it possible to transform any fiber in élite products, the outcome of a constant research of precious results. The same on-going research Biancalani has always believed and invested in.