Comfortable, easy-care and stylish – menswear made from warp-knitted fabrics

Warp-knitted textiles with a woven look are conquering the world of men’s fashion. Jackets, trousers and shirts made from these practical fabrics are often mistaken for woven products, but they offer better easy-care and performance properties. Warp-knitted fabrics are crease-resistant and machine washable and they dry quickly. By using clever patterning and selected yarns, they can also be made up into items with comfort stretch, which deliver freedom of movement and a perfect fit.

Just launder and go!

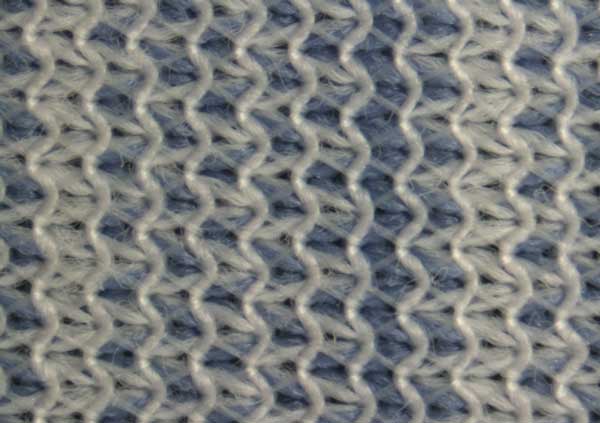

Fabrics for business and casual shirts can be produced on the HKS 3-M high-speed tricot machine in a gauge of E 28. The picture 1 shows an example as a macro photo. The shirt is non-iron, easy-care and comfortable, and is made from polyester and cotton. A fine polyester yarn is processed by ground guide bar GB 1 to form a tricot lapping and GB 3 produces a 2 x 1 lapping with a thicker polyester yarn. With a partial weft lapping made from cotton in-between, GB 2 is responsible for producing a soft, silky feel. The shirt was produced at KARL MAYER.

Warp-knitted textiles for jackets

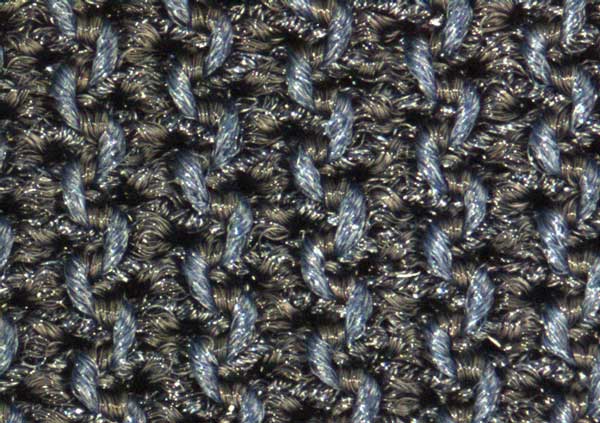

Also jackets can be manufactured from a fabric produced on an HKS 3-M in a gauge of E 28 (Fig. 2). In this application the bicomponent Lycra® T400® fibres give the garment a natural look and feel in particular; they improve the crease resistance and provide elasticity and elastic recovery in every direction. The stretch is perfect for producing comfortable jacket fabrics. Textured yarns and the fabric construction also make another contribution to the elasticity. GB 1 works a 2 x 1 lapping and GB 2 works typically a weft lapping to produce the fabric. This construction produces an unusual elastic recovery behaviour for warp-knitted textiles not containing elastane and has already been used successfully to produce tracksuits. However, GB 2 is fully threaded to produce this item of sportswear. On the other hand, the jacket fabric shown in Fig. 2 was produced with a 1 in, 1 out threading arrangement in GB 2, which means it has a slightly structured surface. With a full threading arrangement, GB 3 works a tricot construction as the ground.