Author: Md. Khalilur Rahman Khan

Former Assistant Professor of Bangladesh University of Business sand Technology / [email protected]

Chemical, biological, radiological, and nuclear (CBRN) hazards are continuously changing in a world where terrorist actions are on the rise.

As a result, CBRN personal protective clothing has gained in popularity around the world, drawing more attention to textile research. It enables personnel to reduce the negative consequences of chemical, biological, radiological, and nuclear threats. Selectively permeable membranes, reactive nanofibers membranes, and other new technologies are being incorporated into improved fabrics for enhanced CBRN protection.

Despite the fact that CBRN protective clothing has benefited from several high-tech developments, there are still many aspects where it could be improved. In this article, it is attempted to review the technologies related to CBRN protective suits, and some of the most successful commercial CBRN protective clothing are also mentioned.

Introduction

Various terrorist attacks or military confrontations in the past have underlined the need of dealing with chemical (nerve and blister agents), biological (bacterial, viral, and biological toxins), radiological (e.g., gamma rays), or nuclear (CBRN) agents. The use of sarin, a toxic chemical agent, in the Tokyo subway on March 20, 1995 was the first large-scale attack by a terrorist group using a toxic chemical weapon.

In October 2001, another CBRN terrorism incident occurred in the United States of America, when letters containing anthrax powder, a biological agent, were sent to many people in the media and State Administration authorities in various states [1]. As a result, assaults involving CBRN (chemical, biological, radiological, and nuclear) agents are becoming a greater threat for global security.

The acronym CBRN (pronounced C-BORN or C-BURN) is a replacement for the cold war term NBC (nuclear, biological, and chemical), which had replaced the term ABC (atomic, biological, and chemical) that was used in the fifties. The “new” threat of a radioactive weapon (also known as “dirty bombs”) prompted the addition of the R (for radiological) [2]. Four types of agents are shown in figure-1. CBRN has been at the forefront of personal protection equipment for a long time (PPE).

In reality, CBRN personal protective equipment (PPE) is a responder’s or warfighter’s first line of protection against an unknown threat. CBRN protective gear may be intended for: first or later responders to CBRN agents, the military, and citizens in dangerous locations [3]. For CBRN events, there are two major threat levels: hot zone operations and warm zone operations.

The employment of a protective ensemble with a self-contained breathing apparatuses (SCBA) is required in hot zones, which are characterized as being immediately threatening to life and health. Warm Zones are defined as areas that are below IDLH (Immediately dangerous to life and health) levels but nevertheless constitute a serious threat, necessitating the use of a respirator as part of the protective gear [4].

Protective textiles (Protech) are clothing and other fabric-related goods that are primarily employed for their protection performance or practical properties, rather than for their aesthetic or decorative aspects. Clothing materials are now commonly utilized as personal protective equipment, and they are classified as technical or industrial textiles [5]. Unlike in the past, there is now a greater need to produce protective clothing against CBRN dangers. Nuclear disasters and an escalation in terrorist activity throughout the world have stimulated new developments in textile research [6]. Furthermore, today’s protective textiles must protect against a wide range of hazards while also meeting a wide range of functional needs [7].

The protective jumpsuit and facemask are the most common types of personal protective equipment (PPE) [8]. Hazardous material (Hazmat) suits were created to safeguard those who work with dangerous substances. CBRN suits are a more specialized version of these suits. Protective garments, such as CBRN protective equipment, should have several functions to help warfighters and first responders improve their deterrence capacities [6]. Furthermore, a good protective garment should provide protection from risks while maintaining the wearer’s comfort and ability to do vital duties [9]. It’s worth noting that scientists are still looking for the best materials for comprehensive CBRN protective apparel.

Manufacturers of protective clothing and equipment have made significant progress in constructing CBRN protective apparel. In this article, it is attempted to list the successful commercial CBRN protective suits after discussing the common principles of CBRN protection.

![Figure-1. CBRN Agents [10].](https://kohantextilejournal.com/wp-content/uploads/2021/10/Screen-Shot-2021-10-18-at-09.52.21.jpg)

Equipment can defend against hazardous materials ingress through a variety of techniques. These include [3]:

• Creating an impermeable barrier between the agent and the individual.

• Filtering, adsorbing, or reacting with dangerous materials to remove them

• Keeping contaminated air away from entry points by using overpressure or directional airflow.

Barrier Materials

Physical protection against CBRN agents entails preventing the physiological absorption of the agents [11]. CBRN apparel constructed of impermeable rubber is air and water vapour impermeable. The former Soviet suit, for example, was made of impermeable rubber-coated canvas. The most agent resistant rubbers are fluorinated rubbers (Viton) and halogenated butyl rubbers [3]. Boots and gloves made of butyl rubber and related materials are still common [12].

Polymers with diverse agent-resistant features can be laminated together to give broad-spectrum permeation protection; polymers can also be mixed to achieve unique properties. Another method for creating impermeable barrier materials is to use nanocomposite materials. The addition of additives in nanocomposite materials can change the structure of polymer membranes, reducing the possibility of chemical leakage. Surface modification can also harden barrier materials to penetration.

This type, however, generates a lot of heat quickly and is uncomfortable; they also reduce human performance to a very low level, which is incompatible with most military missions. Rubber suits have no ability for adsorption; they are just impermeable barriers to CBRN dangers. If self-contained breathing apparatuses (SCBA) are employed, the duration of procedures will be limited. Multiple materials, each of which is resistant to a different agent, can be layered together to build impenetrable barriers [3].

Impermeable protective garments was supposed to give enough protection against chemical warfare agents; but, because they are impermeable and also due to perspiration, they provide an unacceptable barrier to the human body’s natural cooling processes. As a result, one of the most important features of a functional protective suit is that it allows for appropriate body cooling, which is a must. The breathing protection materials have been created to solve the difficulty connected with heat stress. Because of their open porosity nature, these materials are air permeable, which aids in the evacuation of perspiration from the protective suit [13].

Selectively Permeable Material

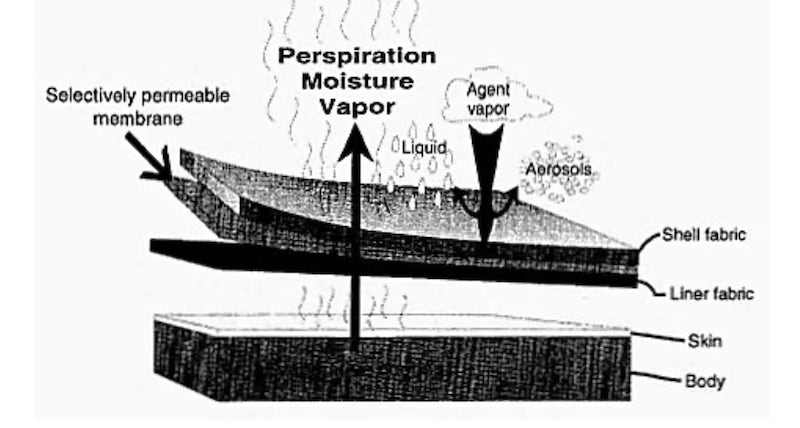

Selectively permeable material allows small molecules to pass through, while blocking bigger toxicant molecules. It has good protective characteristics and can withstand dangerous chemicals such as liquids, gases, aerosols, and solids with a high molecular weight. Furthermore, selectively permeable materials have good moisture permeability (shown in figure-2) and wear comfort, making them a great candidate for permeable protective suits [14].

Although these materials are suitable for protection against biological and radioactive agents, they are not necessarily suitable for total CBRN protection because they are not impervious to chemical or vapor permeation. Microporous and monolithic MVP materials are the two most common types [3]. The Gore company invented super-expanded PTFE film (polytetrafluoroethylene, ePTFE), which is a popular type of microporous barrier.

A PTFE cast film is stretched at a high rate and drawn as a result, without the usual change in its outward dimensions. Millions of small pores form in the structure instead of necking or thinning as it is drawn. The ePTFE material is hydrophobic by nature and has one of the lowest surface energies of any known material. Water vapour, on the other hand, may easily flow through the pores whereas liquid water cannot [15]. The monolithic, considerably less porous structure, however, allows water molecules to diffuse through its elastomeric structure, which is constituted of hydrated entangled polymeric chains. Durability of microporous ePTFE membranes can be increased by laminating them between monolithic MVP layers [3].

The primary method for protecting against agent vapors is activated carbon. This works well with vapors with a higher molecular weight (larger organic compounds). To guard against liquids, activated carbon and barrier materials (shown in figure 3) are employed, and the clothes are frequently finished with liquid repellent properties. Activated charcoal is used to make the porous materials, and the chemical warfare agents are absorbed by the charcoal [13]. When such protective clothing is exposed to contaminated air, the toxic gases carried by the flow are absorbed by the single layer of activated carbon material, leaving the cleaned air free to flow through the protective clothing, ensuring sufficient ventilation for the wearer.

The outer textile layer’s primary function is to reduce the velocity of incoming polluted air flow [17]. While activated carbon adsorption material has good protective capabilities, it also has drawbacks such as non-selective adsorption, poor protection against big poisonous liquid droplets, being heavy (a whole garment weighs around 2.5 kg), and difficulty in disposing of contaminated garments. Permeable protective suit materials will no longer rely solely on the present activated carbon adsorption method as new materials and technologies emerge. The development of permeable protective suits will be accelerated by new materials and technologies in the pursuit of high performance, multifunction, lightweight, and comfort.

![Figure-3: Activated carbon adsorption CBRN protective clothing [17].](https://kohantextilejournal.com/wp-content/uploads/2021/10/Screen-Shot-2021-10-18-at-09.52.47.jpg)

Nanofiber Based Multifunctional Materials

Multifunctional nanofiber-based materials can be incorporated into protective garment systems. Because of the tiny pore size and large surface area of electro-spun nanofibers, electro spun nanofiber membranes have a high aerosol filtering efficiency, good air permeability, low surface density, and low pressure loss [14]. Electrospun fiber-based protective gear can be lightweight while still providing a wide range of capabilities. Electrospun nanofibers or electrospun nanofibers as one of the components of functionalized fabrics could lead to a new kind of protective apparel.

Self-detoxifying electrospun fabrics are a novel type of textile designed to guard against chemical and biological warfare agents, which are typically used in military and terrorist attacks. Personal protection equipment will perform far better as a result. Functional chemicals including cyclodextrin, iodobenzoic acid, polyoxometalates, peroxides, oximes, and chloramines can boost detoxification performance dramatically. It gives up new possibilities for the development of advanced systems that can guard against chemical and biological threats. Electrospun protective clothing is still in development, and commercial production has some constraints [8, 14, 18-19].

On the other hand, metal oxide nanoparticles, such as MgO, CaO, ZnO, TiO2, Al2 O3, MnO2, Fe2O3, and others, also have limits when used to modify the surface of textile fibers. Because the particles may not stay on the fabric surface permanently, particle aggregation is a significant difficulty when covering the fabric surface. The fabric coated with nanoparticles will lose not only its look, but also its flexibility and wear resistance [19].

Smart Second Skin Technology

DTRA’s Dynamic Multifunctional Materials for a Second Skin (DMMSS) program is researching three alternative ways to developing technologies for switchable membrane systems in order to address the inadequacies of traditional PPE. These membranes will close their pores in reaction to chemical substances, but they will remain open when they are not contacted. The new outfits are expected to be deployed in the field in under ten years [20].

The first strategy includes embedding aligned carbon nanotubes (CNT) in membranes. A CNT membrane functionalized with chemical-threat-responsive polymers has two main components: a highly breathable CNT membrane that provides an effective barrier against biological threats; and a thin responsive functional layer grafted or coated on the membrane surface that either closes the vertically aligned CNT pore entrance upon touch with a chemical warfare agent or self-exfoliates in the region of pollutants after the threat has been neutralized. Closing the pore entrance or shedding the contaminated surface layer would cause the fabric to go into a protective mode.

Even though the CNT pores are only a few nm wide and the overall porosity is less than 5.5 percent, these membranes produce water vapor transfer rates that exceed those of commercial breathable fabrics. In both safe and contaminated environment configurations of the polymer chains, the CNT pores are tiny enough to screen out biological hazards [21]. Because of their unique intrinsic cavity structure, mono dispersed nano channels, and transport properties, carbon nanotubes can effectively accelerate the transfer of gas or liquid molecules,, which bring hope for the fabrication of ultralight and super-breathable protective clothing as thin as a cicada’s wings in the future [14].

The second way entails creating an an enzyme embedded copolymer membrane. These membranes expand and close when exposed to chemical agents as a result of an enzyme reaction with the chemical agent, safeguarding warfighters wearing the garment.

A third method involves coating existing fabrics with electrically conductive elements. When subjected to a little electrical current, this coating reacts by sealing the cloth against penetration. In a matter of seconds, the pores close, providing a protective barrier that can last up to 24 hours. A different current can either open the membrane or keep it closed. On carbonized fabrics, this coating has been demonstrated [20].

Metal-organic Frame Materials

Metal–organic frameworks (MOFs), which are porous crystalline materials with a wide chemical and structural variety, have sparked academic and industrial attention. Metal organic frameworks are porous crystalline solids made up of metal ion units or clusters linked together by bitopic/polytopic organic linkers and held together by strong coordination bonds. Because of their excellent adsorption, reactivity, and catalytic capacity toward CWAs, MOFs have been identified as one of the most important materials for detecting and detoxifying Chemical warfare agents (CWAs) [22, 23].

Micro-capsule Self-healing Techniques

Micro-capsule self-healing mechanisms aid in the establishment of a good physical barrier to lethal chemical agents, bacteria, and viruses, ensuring that humans are protected in a timely and consistent manner [14]. The technology combines novel gap-closing techniques with healing micro-capsules that activate when ripped, allowing cuts and punctures to be repaired. The self-healing layer contains reactive compounds that neutralize harmful threats, such as lethal chemicals, while also reforming the physical barrier against bacteria and viruses [24].

Personalized Protective Biosystem (PPB)

The Defense Advanced Research Projects Agency’s (DARPA) personalized protective biosystem (PPB) program will integrate novel, lightweight protective materials with innovative prophylactic medical technologies to reduce chemical and biological dangers at vulnerable tissue barriers, such as the eyes, skin, and lungs. It is divided into two Technical Zones (TAs): TA1 – reactive materials that restrict CB agents from entering the body; and TA2 – a programmable barrier countermeasure (BCM) that neutralizes 10 CB agents at vulnerable entrance locations (i.e., skin, airway, ocular).

The design should also reduce the donning process to less than 10 minutes. Above all, the program will use molecular components or commensal organisms at key places of susceptibility to relieve the user of the burden of protective equipment. Successful PPB technologies have the potential to revolutionize how the military and public health respond to unforeseen threats [25, 26].

GORE® CHEMPAK® Fabric Technology

Toxic industrial chemicals, chemical warfare agents, infectious illnesses, synthetic opioids, and biological and radiological particle threats are all protected by Gore® Chempak® fabrics. Gore® Chempak® selectively permeable fabric and Gore® Chempak® ultra barrier fabric are two material technologies that are created to fulfill the needs of their desired final [27].

i) Gore® Chempak® Selectively Permeable Fabric

The industry’s first breathable perimeter-response (warm zone) garments are made of Gore® Chempak® selectively permeable materials. This fabric offers great levels of protection while putting the person under minimal physiological stress. Gore® Chempak® selectively permeable fabric is approved to NFPA 1994, Classes 3/3R and 4/4R, as well as NFPA 1992 Standards, for superior protection in warm zone activities against NFPA-identified threats as well as extra toxic industrial chemicals (TICs) and chemical warfare agents (CWAs).

Gore’s barrier allows sweat vapor to exit through the suit while retaining a minimum of four hours of permeation protection, reducing heat stress. The form-fitting garment is meant to allow the responder to move more quickly and effectively in hazardous environments, confined areas, and rubble piles, with increased padding at crucial stress points for enhanced cut and puncture protection. It’s excellent for defense, emergency, or law enforcement workers in high-stress, fast-paced operations that aren’t IDLH (immediately harmful to life and health) [27].

ii) Gore® Chempak® Ultra Barrier Fabric

PPE clothing made of Gore® chempak® ultra barrier fabric are ideal for tactically challenging operations including search and rescue, technical rescue, SWAT and high-risk entry, hazardous material emergency, WMD or terrorist incident, containment, and decontamination. Gore® Chempak® ultra barrier fabric is made up of three layers: an impermeable high-strength fluoropolymer barrier film, two flame- and melt-resistant textile layers, and a three-layer construction.

The outer layer is a high-strength cloth that withstand cuts, tears, and punctures for additional longevity and abrasion resistance. While enabling extensive chemical protection, this lightweight and flexible multi-layer fabrication improves garment fit and comfort. Gore® Chempak® ultra barrier fabric is approved to satisfy both the NFPA 1994 standard on protective ensembles for first responders to CBRN terrorism situations, Class 2, and the NFPA 1992 standard on liquid splash-protection ensembles and garments for hazardous materials incidents [28].

Saratoga® CBRN protective clothing

SaratogaTM, a proven technology established by Blücher GmbH in Germany, provides adsorption capacity and the highest possible comfort in all climatic situations. SaratogaTM is made up of spherical activated carbon absorbers attached to a textile carrier fabric to provide the finest possible flow conditions for body heat dissipation. Under any climatic situations, the two layers and air gap ensure comfort and efficient heat management of the body.

Extra security against chemical warfare chemicals in liquid, vapor, and aerosol forms is provided by activated carbon. SaratogaTM is a proprietary composite filter fabric made up of highly activated and rigid carbon spheres attached to a textile carrier. It provides a minimum of 24 hours of protection and at least 45 days of use under battlefield circumstances, including many field washings, with a carbon density of 180 g/m2 to 220 g/m2, the highest on the market. Over 85% of the sphere’s outside surface is fully accessible to hazardous gases, resulting in a fast and effective adsorption.

Sweat impulses are captured and continually degraded thanks to the SaratogaTM spherical absorbers’ pore structure and hydrophilic qualities. This results in a low increase of humidity and low ambient humidity in the skin’s immediate vicinity. SaratogaTM is comfortable to wear as a result of this. SaratogaTM filter materials’ great flexibility causes a “pump effect,” which improves the microclimate by allowing for rapid air exchange between the inner and outer textile layers. The garments are also very air permeable, which reduces sweating and heat stress [29].

Commercial CBRN Protective Suits

1. Tex-Shield’s JSLIST suits

The JSLIST (Joint Service Lightweight Integrated Suit Technology) is a two-piece, front-opening suit that is light and comfortable. This suit can be worn as an overgarment or as a primary suit over underwear. A two-layer fabric system with a proprietary liquid resistant nylon/cotton outer shell fabric and a SARATOGA@ carbon spherical liner is used in the suit.

Small spheres of adsorbent carbon embedded in the real fabric replace bulk charcoal (found in the previous Battle Dress Overgarment, BDO) or carbon in JSLIST suits and its counterparts. The JSLIST retains its PPE qualities for 120 days after being opened, can be worn continuously for 45 days, and can be washed six times. The JSLIST can be worn for up to 24 hours in a polluted environment. The Uniform Integrated Protective Ensemble (UIPE) line of products has taken the position of JSLIST. The UIPE project has included Gore and Paul Boye, among others [12, 30].

2. Blauer’s Homeland Defender ® suits

Homeland Defender® suits are designed to be exceptionally rugged in terms of fabric and seam structure, allowing for worry-free tactical, rescue, and Decon operations without the use of chemical tape. If the Homeland Defender® suits are not polluted, they can be reused numerous times [31].

Multi-Threat suits

Blauer’s Multi-Threat ensemble provides the highest level of protection from liquid and vapor forms of HAZMAT and CBRN substances in the Homeland Defender® line. When worn with approved SCBA systems, the suit is made of Gore chempak ultra-barrier fabric and is certified to NFPA 1994 Classes 1 and 2 and NFPA 1992 for protection against chemical warfare agents (CWAs) and toxic industrial chemicals (TICs) at concentrations at or above IDLH.

This unique non-permeable membrane is bonded to a 4.5 ounce Nomex IIIA outer and inner shell for enhanced protection, which offers excellent static dissipative performance and resists melting, dripping, and burning when exposed to high heat and flame. The Nomex® IIIA outer shell has been engineered to absorb water without compromising the integrity or protective performance of the underlying Gore® chempak® barrier.

When the wearer wets the suit with water before or during use, the water evaporates from the outer shell, providing a natural cooling effect comparable to sweating [32]. The responder’s metabolic heat has been demonstrated to be successfully dissipated by wetting down the clothing. The user will be more comfortable and able to stay on scene in case of periodic wetting. This protective gear gives the wearer mobility, dexterity, fit, and comfort [28].

Blauer’s RC3® ensemble

The XRT ensemble from Blauer is certified to the NFPA 1994 standard for Class 3 protection against liquid and vapor CBRN agents, as well as NFPA 1994 Class 4 protection against radiological and biological particles at levels below IDLH. The XRT suit is made of Gore chempak selectively permeable fabric, making it lightweight and breathable for comfort during extended response activities. The one-piece design of the suit, which includes an integrated glove system and booties, avoids the need for chemical tape and allows first responders and consequence management staff to self-don the suit quickly [32].

XRT Response Suit

Blauer manufacturing company’s XRT response suit is a single-piece coverall that doesn’t require taping and allows law enforcement officers to respond faster and stay on the scene for up to eight hours. The NFPA 1994 requirement for Class 3 protection against liquid, vapor, and particle CBRN agents at levels below IDLH has been met by Blauer’s XRT ensemble [32].

Blauer’s BRN-94® Ensemble

Blauer’s BRN-94® Ensemble is the first purpose-built PPE to be certified to both the NFPA 1994 standard on protective ensembles for first responders to CBRN terrorism incidents for CLASS 4 protection against radiological and biological particulate threats and the NFPA 1999 ensemble standard for protection against blood-borne pathogens, body fluids, and common chemicals. The Gore® crosstech® fabric used in the BRN-94 ensemble provides long-lasting protection against liquid and particle biological and radiological hazards. The BRN-94, like the other Homeland Defender® CBRN ensembles, is self-sealing and does not require chemical tape [32].

3. Lion Group’s Suit

ERS (Extended Response Suit)

The ERS (Extended Response Suit) is a one-piece, front-entry suit composed of lightweight Gore® chempak® selectively permeable fabric that is certified for “warm zone” work. When used in conjunction with the appropriate ensemble elements, the ERS defends against lower levels of vapor and liquid concentrations that may be found in the “warm zone.” It has NFPA 1994 Class 3 (Toxic industrial chemical and warfare agent protection) and NFPA 1992 (Liquid splash) certifications [33].

MT94™ Multi-Threat CBRN Garment

Thin, lightweight, high-strength PTFE film is sandwiched between durable DuPontTM Nomex® outer and inner layers in the rugged GoreTM chempak® ultra barrier fabric. It is certified to NFPA 1994, Class 1, Class 2, and NFPA 1992 for hot zone activities. It guards against hazardous waste, drug labs, biological threats, and domestic terrorism agents [34].

4. CBRN MK-V SUIT

It is made of a composite fabric that includes an exterior shell fabric that is flame retardant (FR), water repellent (WR), oil repellent (OR), antistatic, and camouflage printed, and an activated carbon sphere (ACS) coated filter cloth. Depending on the weather, the CBRN suit can be worn over appropriate underwear. The CBRN suit is compatible with various protective gear, such as the CBRN Boot Mk II/Overboot Mk II, CBRN Respirator Mk II/Integrated Hood Mask Mk II, CBRN Gloves Mk II, and Haversack Mk II. The item has been accepted by the Indian Army, and it is currently being mass produced [35].

5. OPEC CBRNe

OPEC CBRNe Ltd is a designer and manufacturer of Level C CBRN protective suites with a high level of comfort and protection. The most common CBRN protective clothing offered by OPEC CBRNe Ltd is the Phoenix CBRN Protection Suit, Kestrel, Falcon, Cetan CBRN Protection Suit, and Harrier CBRN Glove. In 2019, Australian Defence chose their leading product, the Kestrel, as their preferred system. The Cetan CBRN Protection Suit, which will be available in 2021, is a medium-weight garment that provides comprehensive chemical warfare protection for modern soldiers during high-risk missions. The two-piece garment meets NATO AEP38 CBRN protection levels.

6. Survitec’s CBRN Suit

Sonics Bio Skin

The bio-skin’s chemical and biological properties, which are based on the most recent Gore® chempak® selectively permeable membrane (SPM), give optimal protection while minimizing thermal burden [37].

Sonics Bio-Shell

With up to a 50% weight reduction over traditional carbon-based protective clothing, Gore® CPCSU-2 flex fit technology combats a much broader threat, acting as a barrier against conventional chemical warfare agents in vapor form, toxic industrial chemicals, aerosolized particulates, liquid under force (i.e. when kneeling or wearing combat equipment), and biological hazards such as bloodborne pathogens like Ebola. In addition, the Bio-core Shell’s layer is made of the most up-to-date Gore® chempak® selectively permeable membrane (SPM) [37].

7. Demron™ by Radiation Shield Technologies (RST)

Radiation Shield Technologies is the world’s leading manufacturer of multi-hazard universal protective clothing. DemronTM is a proprietary nano-composite developed by RST® that provides unparalleled protection against chemical, biological, radiological, nuclear, and ballistic (CBRNE) threats. It is also self-cooling and lowers IR detection due to its thermo conductive characteristics. DemronTM minimizes heat stress by dissipating heat more effectively than other impermeables. Demron® is now available in full body suits, blankets, tents, and other products to protect people in the event of a radiological or nuclear disaster [38].

8. Polycombi® CBRN Protective Suit

Polycombi® is a permeable coverall that protects for 12 hours against NRBC agents in liquid, vapor, and aerosol form [19]. CBRN protective suit of Ouvry company is shown in figure-4.

![Figure-4. CBRN Protective Suit [19]. [Image Courtesy: https://www.ouvry.com/en/produit/polycombi-cbrn-protective-suit/]](https://kohantextilejournal.com/wp-content/uploads/2021/10/Screen-Shot-2021-10-18-at-09.53.11.jpg)

ChemMAX 3 garments are suitable as a first line of defense because they are quick to put on. ChemMAX 3 is made with a cutting-edge, one-of-a-kind multi-layer combination of films and tie layers that provides a superior barrier to a wide range of hazardous compounds while preserving a soft, flexible, and quiet fabric.

10. Kappler’s DuraChem® 500

The NFPA 1994-compliant DuraChem® 500 is excellent for both general hazmat and terrorism event response. It features dual NFPA 1994 certification for both Class 1 and Class 2, as well as tactical CBRN protection in a non-encapsulated suit. It is far more cost effective than pricey reusables because it is designed as a’multi-use, single-exposure’ garment [39].

11. Chemviron Carbon’s Zorflex®

Zorflex® is utilized in protective garments, filters, and decontamination wipes to provide protection against a wide spectrum of chemical, biological, and nuclear hazards. In comparison to other materials such as embedded carbon, carbon fixed to support media, or membrane technologies, Zorflex® activated carbon cloth uses the most cutting-edge filter technology for clothing [40].

12. Geomet Technologies DTAPS Suits

For civilian and military first responders, Geomet Technologies has developed the new disposable toxicological agent protection systems (DTAPS).

13. Paul Boyé CBRN Suits

14. Seyntex CBRN Suits

15. Ansell’s Trellchem ACT CBRN Suit

References

1. Magalhães M.J., de Magalhães S.T., Revett K., Jahankhani H. (2016) Chemical, Biological, Radiological and Nuclear (CBRN) Protective Clothing – A Review. In: Jahankhani H. et al. (eds) Global Security, Safety and Sustainability – The Security Challenges of the Connected World. Springer, Cham. https://doi.org/10.1007/978-3-319-51064-4_26

2. http://www.nitratextile.org/coeprotech/web/content/pdf/updates-2012.pdf

3. Eva F. Gudgin Dickson, Personal protective equipment for chemical, biological, and radiological hazards: Design, Evaluation, and Selection, 2013 by John Wiley & Sons, Inc. New Jersey.

4. https://www.ilerisavunma.com/en/cbrn-protection/multi-threat-cbrn-garment

5. Bhuiyan, M. A. R., Wang, L., Shaid, A., Shanks, R. A., & Ding, J. (2018). Advances and applications of chemical protective clothing system. Journal of Industrial Textiles. doi:10.1177/1528083718779426

6. Roshan Paul, Functional Finishes for Textiles: Improving Comfort, Performance and Protection, Woodhead Publishing, Cambridge, UK, Copyright © 2015 Elsevier Ltd.

7. Degenstein LM, Sameoto D, Hogan JD, Asad A, Dolez PI. Smart Textiles for Visible and IR Camouflage Application: State-of-the-Art and Microfabrication Path Forward. Micromachines. 2021; 12(7):773. https://doi.org/10.3390/mi12070773

8. Introduction to Electrospun Fibers for Defence Technology, November 2015, Electrospin Tech, retrieved from http://electrospintech.com/defenceintro.html#.YWU9W9pBzIX

9. Bhattacharjee, S., Joshi, R., Chughtai, A. A., & Macintyre, C. R. (2019). Graphene Modified Multifunctional Personal Protective Clothing. Advanced Materials Interfaces, doi:10.1002/admi.201900622

10. https://www.hsdl.org/?view&did=477641

11. STO technical report, Integration of CBRN Physical Protective Measures to Lessen the Burden on Personnel, June 2018, Copyright © STO/NATO 2018. https://apps.dtic.mil/sti/pdfs/AD1062099.pdf

12. Dan Kaszeta, CBRN Protective Clothing – Advances in Textiles and Technologies, October 2021, European Security & Defence , https://euro-sd.com/

13. Boopathi, M., Singh, B., & Vijayaraghavan, R. (2008). A Review on NBC Body Protective Clothing. The Open Textile Journal, 1, 1-8.

14. Zhao, X. & Liu, B.. (2018). Permeable Protective Suit: Status Quo and Latest Research Progress. Cailiao Daobao/Materials Review. 32. 3083-3089 and 3098. 10.11896/j.issn.1005-023X.2018.17.022.

15. R. A. Chapman, Smart textiles for protection, 2013, Woodhead Publishing Limited, pp.60.

16. Schreuder-Gibson, H.L., Truong, Q., Walker, J.E. et al. Chemical and Biological Protection and Detection in Fabrics for Protective Clothing. MRS Bulletin 28, 574–578 (2003). https://doi.org/10.1557/mrs2003.168

17. Davide Ambesi, Flow, heat and mass transfer through CBRN protective clothing, 2013.

18. Petkov, Plamen, Achour, Mohammed Essaid, Popov, Cyril (Eds.), Nanoscience and Nanotechnology in Security and Protection against CBRN Threats, © Springer Nature B.V. 2020.

19. https://www.ouvry.com

20. A second skin for the first layer of defense,

https://www.dvidshub.net/news/284620/second-skin-first-layer-defense

21. Bui, N., Meshot, E. R., et al. (2016). Ultrabreathable and Protective Membranes with Sub-5 nm Carbon Nanotube Pores. Advanced Materials, 28(28), 5871–5877. doi:10.1002/adma.201600740

22. Ma K., Idrees K., et al. (2020). Fiber Composites of Metal–Organic Frameworks. Chemistry of Materials. 32. 10.1021/acs.chemmater.0c02379.

23. Selva B., Jayalatha A., et al. (2021). Metal Organic Framework Functionalized Textiles as Protective Clothing for the Detection and Detoxification of Chemical Warfare Agents—A Review. Industrial & Engineering Chemistry Research. 60. 10.1021/acs.iecr.0c06096.

24. Jane Benson, U.S. Army Investigates Self-Healing Protective Clothing, December 1, 2015, https://www.designworldonline.com/u-s-army-investigates-self-healing-protective-clothing/

25. https://na.eventscloud.com/file_uploads/13291415808e0dc92d4ddb38c79d2a39_DARPA-SN-20-10.pdf

26. https://www.darpa.mil/program/personalized-protective-biosystem

27. https://www.goretexprofessional.com/technologies/gore-chempak

28. https://www.goretexprofessional.com/sites/tof/files/2020-07/GORE%20CHEMPAK%20products%20-%20Multi-threat%20suit_expanded%20info.pdf

29. Karkalic R., Maslak V., et al. (2015). Application of permeable materials for CBRN protective equipment. Zastita materijala. 56. 239-242. 10.5937/ZasMat1502239K

30. Gonzalez, Julio & Potter, Adam. (2020). Quantitative Comparison of two Chemical Biological Protective Suits: The Joint Service Lightweight Integrated Suit Technology (JSLIST) and the Tactical Advanced Threat Protective Ensemble (TATPE). 10.13140/RG.2.2.16556.82562.

31. https://www.blauer.com/chembio

32. Blauer-Homeland-Defender-Brochure-2019 Available from https://www.blauer.com/wp/wp-content/uploads/2019/04/Blauer-Homeland-Defender-Brochure-2019.pdf

33. https://www.fire-end.com/image/catalog/PDF%20Specs/Lion-ERS-Suit.pdf

34. https://www.rotemsafety.co.il/sites/default/files/LION%20MTcombo.pdf

35. https://www.drdo.gov.in/sites/default/files/inline-files/DEBEL-8.pdf

36. https://opeccbrne.com/

37. https://survitecgroup.com/media/344584/s_sonics-cbrn_brochure.pdf

38. https://radshield.com/wp-content/uploads/2021/05/RST-Demron-Catalog-Dec-2020.pdf

39. https://kapplerchemicalsuits.com/wysiwyg/PDFs/Kappler/KAP-DuraChem-200.pdf

40. http://www.neuni-materio.com/wp-content/uploads/media-files/11/11759-chemviron.pdf