On the occasion of this year’s nonwovens exhibition INDEX in Geneva from 18 to 21 April 2023, the world’s leading manufacturer of textile machinery BRÜCKNER will not only inform about its well-known delivery program which includes almost all types of dryers, thermofusion and heat-setting ovens with mainly convective heat transfer, but also about the latest trends in machinery technology and the related process technology.

In the last years BRÜCKNER realized some very challenging projects in the nonwovens industry. These include lines for the heat-setting of geotextiles, finishing lines for nonwovens in medical technology as well as thermofusion lines for the bonding of voluminous nonwovens for the furniture industry.

Besides the current sales successes, the continuous further development of the processes and the associated line technology plays a decisive role for the German world market leader. The basis of each BRÜCKNER line is the technologically best possible line configuration, which is always individually tailored to the customer and his needs.

For this purpose, customers and interested potential customers can carry out tests in BRÜCKNER’s Technology Center at any time. Heat-setting, thermofusion, coating, laminating, drying and finishing tests can be carried out on two lines in production scale.

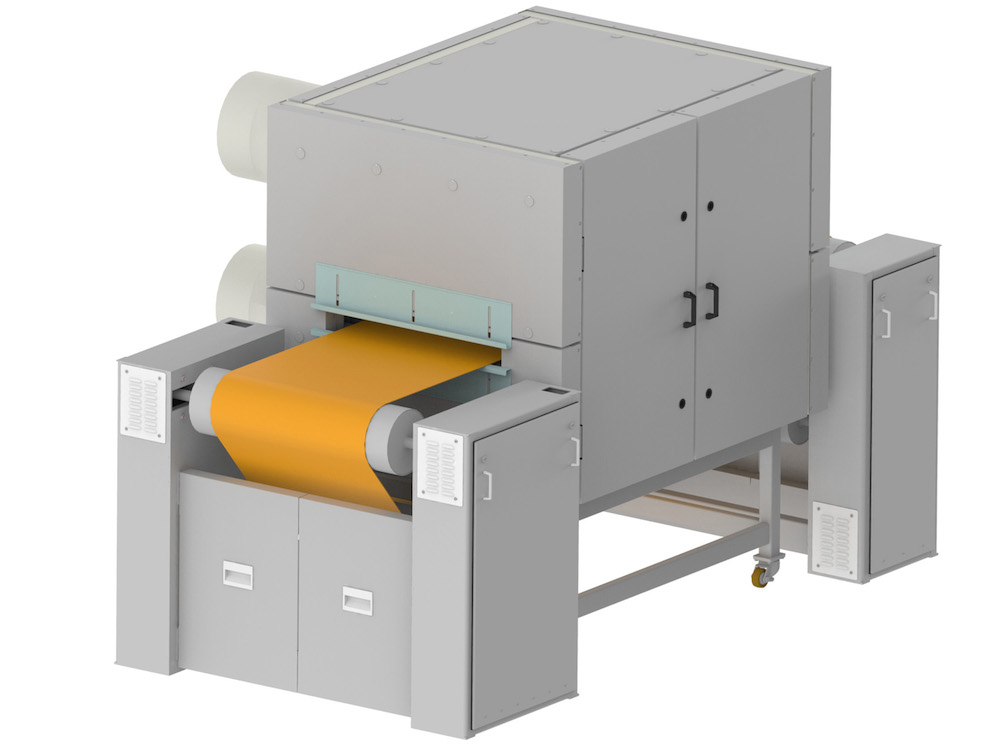

In order to provide even better support in the future, especially for customers in the nonwoven production sector, a flow-through belt oven was added to the range of test machines at the BRÜCKNER Technology Center at the beginning of the year.

This is a small and compact thermo treatment line which, due to its short length, is excellently suitable to simulate also fast running processes with short dwell times at moderate test speeds. The electrically heated unit is equipped with all relevant sensors for measuring the local system pressures, the air volumes, the air temperatures, the material surface temperature and the process air humidity.

BRÜCKNER’s sales engineers will be pleased to advise you at the INDEX in hall 1, booth 1580 about the concrete possibilities for the optimization and development of nonwoven products in BRÜCKNER.