Interview with Rini Bansal / Director- Business Development at Carbon Light pvt. Ltd

By: Behnam Ghasemi / Kohan Textile Journal

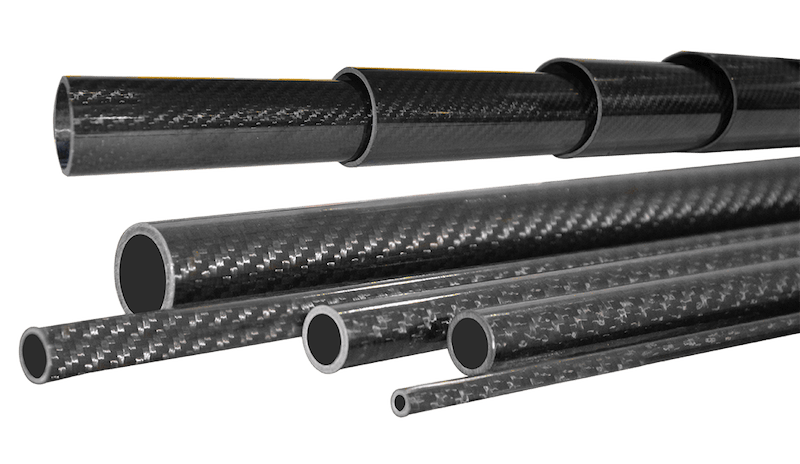

Carbon Light specializes in designing and manufacturing of carbon fiber composite components for various industrial, Medical, Textile and Nonwoven, Aerospace and Defence applications. Carbon Light highly supports out-of-the-box thinking by customizing products as per design and need.

Our Vision is to provide an efficient environment of quality service and supplies by exploring new markets closely and show a competitive edge in all aspects through loyalty and honesty.

What is the Carbon light range of products and specifications?

• For the industrial sector, carbon light supplies carbon fiber bands for wind mill and lightweight rollers for nonwoven textiles, blow film printing, slitting, packaging and converting machines.

• For the aerospace sector carbon fiber tubes and sheets as landing gears, base frames, and molded components to drone/UAV companies.

• For defense applications, launch tubes for various missiles and rocket launchers.

• For the Medical sector, carbon fiber x-ray table tops, Wilson frames, Relton frame, etc

A- Carbon Fiber Rollers:

Key advantages and features:

Categories of rollers:

– Dancer rollers

– Idler/guide rollers

– Lay on rollers

– Nip rollers

– Parallel sleeves rollers

– Pull rollers

You are among the limited companies that produce Carbon fiber rollers which are used in needle punch machines at cross lapper. Please explain more about the advantages and usage of carbon fiber rollers in different industries.

Carbon fiber roller possesses striking features such as high strength-to-weight ratio, corrosion resistance, electrical conductivity, high thermal conductivity, and high tensile strength among others.

Delhi-NCR-based designer and manufacturer of carbon Fiber components, Carbon Light Private Limited manufactures carbon fiber composite rollers for packaging, paper and film, mining, printing, rubber, nonwoven, slitting, food, and other industries. Carbon Fiber rollers have been long used in a number of converting applications as the lower weight and inertia of the rollers support faster web speeds and reduce vibration.

Carbon fiber is twice as stiff and has lower density than steel. Metal rollers need to be powered and controlled by complex electronic systems to avoid stretch and damage on films, but the lightness of carbon fiber allows the use of fewer motors, electronic drives, and control systems.

Used by several customers in India as well as foreign countries, Carbon Light has been involved in manufacturing carbon fiber rollers for the last eight years and doesn’t plan to manufacture metallic rollers at all, even though 95% of the market is dominated by metallic rollers.

Key advantages:

• Light in weight

• Higher roller speeds

• Low movements of inertia

• Higher specific stiffness

• Thermally stable

Unique Features:

• Strength – 6 to 8 times stronger than steel & aluminum

• 75 percent quicker compared to steel 30-35 percent lighter than aluminum

• Rigidity- 2.5 times higher as compared to aluminum

• Damping- vibration damping is quite non

• Acceptable for high-speed software

• Moment of inertia- low

• Corrosion and chemical resistance

• Electrically conductive

Types of Our Carbon Fiber Rollers:

• Accumulator rollers • Conical sleeves • Dancer rollers

• Air shafts • Contact rollers • Guide rollers

• Calendar rollers • Conveyor rollers • Idler rollers

• News printing rollers • Parallel sleeves • Pull rollers

• Nip rollers • Pinch rollers • Reel spools

• Impression rollers • Lay on rollers • Load cell rollers

• Roll cores • Tension rollers

Dynamic Material-Controlling Vibrations Vibrions will usually occur when parts are in a machine. In most of cases, these vibrions are undesirable as they reduce process dynamics and precision while increasing the wear on individual components. Thanks to the specific material prosper, carbon fiber composite possesses high damping Rao which can be further modified by optimized designing of lay-up.

How do you evaluate the textile machinery manufacturer industry in India in general?

We are supplying our roller in two types of textiles machines:

A- Spun Bonding Machines: Spun bond nonwoven fabrics are composed of continuous filaments produced by an integrated fiber spinning, web formation and bonding process. As it eliminates intermediate steps, it is the shortest textile route from polymer to fabrics in one stage and provides opportunities for increasing production and reduction of cost.

B- Needle Punch Machines: Needling is the most universal bonding method in the nonwovens sector with a percentage of over 50 %. Needle punch can be used for a wide range of fabric weights and fiber fineness, and due to the mechanical operating principle are extremely economical with resources. All types of fiber, man-made, natural, mineral and metal can be needled.

How many percent of your machinery export to international markets and how many percent use in India local market? Where are your main export destinations and countries?

Carbon light manufactures carbon fiber roller which is used in textile machines. Our Focus segment needle punch machine. There are some companies like Dornier, Andrity, and Dilo Group.

In India, we are replacing the metallic rollers in our carbon fiber rollers. Our rollers are 2x stiff in use. If we talk about the global market we are searching the source of distributors and resellers for replacing the metallic rollers for needle punch and spun bond machinery.

What are your product’s advantages in comparison with other brands in terms of price and quality?

Precise Design: Each roller being manufactured is designed to the exact customer application requirements. Proper material selection and design considering help us deliver high-performance lightweight rollers to satisfy each requirement.

Coatings Options: To keep up with the ever-evolving nature of materials being processed, we develop coatings to overcome such challenges. Customers can choose from a range of elastomeric, metallic and ceramic coatings.

Balancing: Static and dynamic balancing of these rollers is very crucial to ensure long service life as well as uninterrupted performance. To achieve this, each roller is balanced as per the desired grade according to ISO 1940.

Bonding: The joint between the metallic hub/ journal and composite tube is achieved by bonding using high strength adhesives. Extensive type testing and prototyping has been conducted to qualify this technology to hold the joint in place.

Interchangeability: Owning an existing machine with metallic rollers does not mean that you cannot enjoy the benefits as offered by composite rollers. With the help of our technical team and our design capabilities, we offer 100% interchangeable rollers with all the benefits on your existing machine.

Repair Service: For machines that came pre-defined with composite rollers, we offer repair services to make damaged rollers as good as new. Rollers undergo gradual degradation over years of operation. Being such precious pieces of machinery, no need to throw them away when they can be repaired to regain their original thickness.

Constant Development: We at carbon light are always involved in continuous research and development, as of now we have developed different type of coatings for Carbon Fiber Rollers to make it more durable and to cater customer’s problems raised in web handling/ processing. We are always ready to adopt/ incorporates new technologies to best suit the requirements.

Production and consumption of Indian textile machinery and spare parts in last decade grow fast. What are the reasons for this?

The Indian textile industry is one of the largest in the world with a massive raw material and textiles manufacturing base. Our economy is largely dependent on textile manufacturing and trade in addition to other major industries. About 27% of the foreign exchange earnings are on account of the export of textiles and clothing alone.

The textiles and clothing sector contributes about 14% to industrial production and 3% to the gross domestic product of the country. Around 8% of the total excise revenue collection is contributed by the textile industry.

So much so, the textile industry accounts for as large as 21% of the total employment generated in the economy. Around 35 million people are directly employed in textile manufacturing activities. Indirect employment including the manpower engaged in agriculturally based raw-material production like cotton and related trade and handling could be stated to be around another 60 million.

INDIAN TEXTILE INDUSTRY STRUCTURE AND GROWTH:

India’s textile industry is one of the economy’s largest. In 2000/01, the textile and garment industries accounted for about 4 percent of GDP, 14 percent of industrial output, 18 percent of industrial employment, and 27 percent of export earnings (Hashim). India’s textile industry is also significant in a global context, ranking second to China in the production of both cotton yarn and fabric and fifth in the production of synthetic fibers and yarns.

In contrast to other major textile-producing countries, mostly small-scale, nonintegrated spinning, weaving, cloth finishing, and apparel enterprises, many of which use outdated technology, characterize India’s textile sector. Some, mostly larger, firms operate in the “organized” sector where firms must comply with numerous government labor and tax regulations. Most firms, however, operate in the small-scale “unorganized” sector where regulations are less stringent and more easily evaded.

The unique structure of the Indian textile industry is due to the legacy of tax, labor, and other regulatory policies that have favored small-scale, labor-intensive enterprises while discriminating against larger-scale, more capital-intensive operations. The structure is also due to the historical orientation towards meeting the needs of India’s predominately low-income domestic consumers, rather than the world market.

Policy reforms, which began in the 1980s and continued into the 1990s, have led to significant gains in technical efficiency and international competitiveness, particularly in the spinning sector. However, broad scope remains for additional reforms that could enhance the efficiency and competitiveness of India’s weaving, fabric finishing, and apparel sectors.

Please let us know about Carbon light company’s history and its success story.

Carbon Light provides consultation in designing as it has immense experience and an expert team.

• Highly experienced team in CFRP composite.

• ISO 9001:2015 (QMS), 14001:2015(EMS) & OHSAS 45001:2018

• Over 6500 sq.mtr. area of manufacturing facility in NCR (National Capital Region)

We’ll deliver the timely delivery of products whose performance and appearance are in accordance with our tradition of high manufacturing standards.

Our ambition is to be a retailer with the capability to see opportunity on the horizon and have a clear path to capitalize on it. To do so, we’re moving more briskly than ever ahead, employing additional technology and concentrating our resources on those rudiments most important to our core customers.

Mission:

• Strive for Customer satisfaction through quality service and perpetual communication

• Provide products that meet the customer’s expectations by teaming up with well-established international suppliers.

• Promote up-to-date products that will give the customer a competitive edge

• Engage highly qualified employees, who will ensure the constant progress of the company and the continued service to the customer.