“Transforming the World of Textiles” – this is the motto for this year’s ITMA, the world’s largest international textile and garment technology exhibition, which takes place from 8 – 14 June in Milan. The four official themes for the trade show are “Automation and Digital Future”, “Advanced Materials”, “Sustainability and Circularity” and “Innovative Technologies”. These themes also play a prominent role in the exhibits of the Jakob Müller Group.

Sustainability and the circular economy – these concepts have been more than mere buzzwords for some time now, and today they are fundamental market requirements that need to be met. In view of rising energy costs and the scarcity of raw materials, companies have to manage a balancing act and ensure that production is both sustainable and commercially profitable.

However, today this also means increasing use of recycled and biodegradable yarns. With its exhibits at ITMA 2023, the Jakob Müller Group is responding to these market requirements and showing that these types of raw materials can be efficiently processed into attractive products on the company’s machines.

All narrow fabric weaving and label weaving machines – with the exception of the MD 2/130 – are pre-configured ready for integration into a network and can be connected via “mymuenet®”, the digitalization portal of the narrow textiles industry. These machines are also equipped with the MLC machine control system and the MÜDATA® M-series control platform as standard.

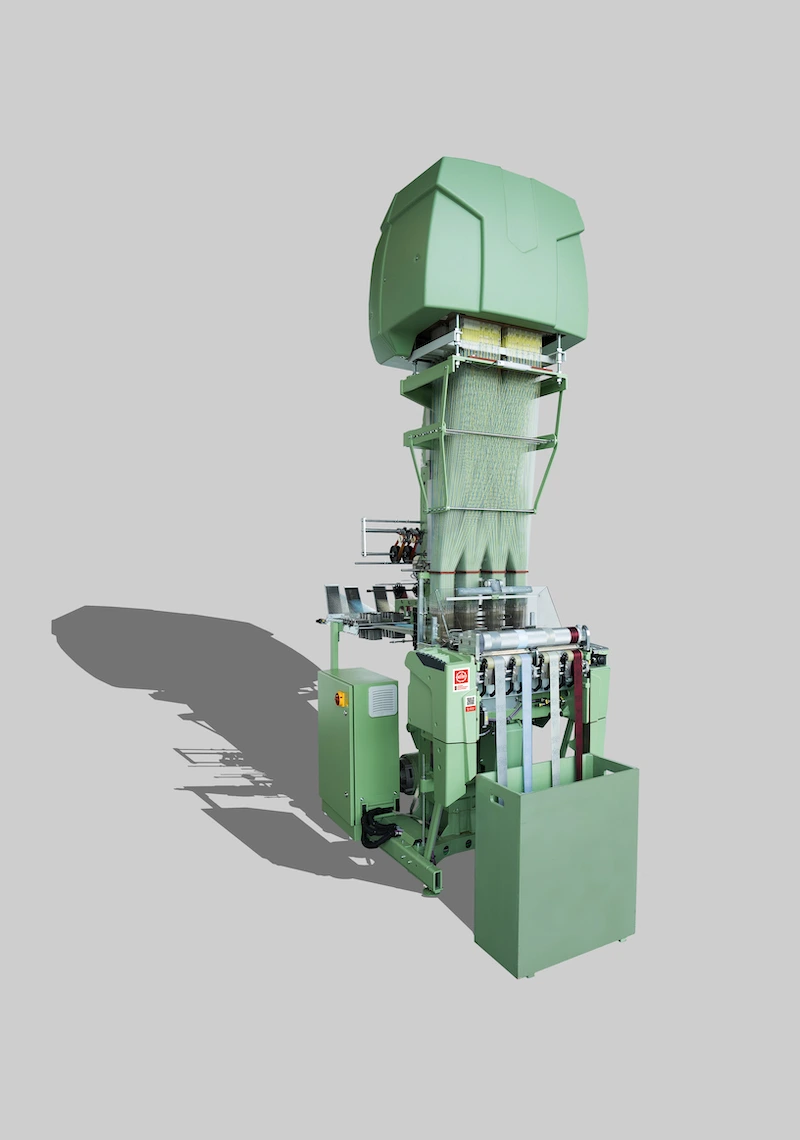

Narrow fabric weaving

The electronically controlled Jacquard needle weaving loom NFMJ 53 4/66 is equipped with a Jacquard loom of type SPE3, which is loaded with 576 hooks. The weft and binder thread feeds are controlled electronically, as is the tape take-off, which enables weft densities of 4 to 120 wefts/cm.

The supply of elastic threads is implemented via a driven double roller system. The raw material for the basic, figure and weft threads is TENCEL® Lyocell with a fineness of 167 dtex. The elastic threads consist of elastic biopolymer with a fineness of 110 dtex, wrapped with TENCEL® Lyocell. The weaving system produces elastic tapes for undergarments.

In the version displayed at the trade show, the high-performance narrow fabric loom NFM® 53 2/130 has two MÜTRANS® thread transport systems operating independently of each other, which allows different weft materials to be processed and/or two products with different tape widths to be produced at the same time. The supply of elastic yarn is implemented via an electronically controlled and driven double roller system.

The warp material consists of recycled polyester filament with a fineness of 330 dtex. Recycled polyester filament is also used in the weft – with 167 and 330 dtex. The tape take-off enables weft densities between 4 and 120 wefts/cm. The weaving system on display is shown with an elastic narrow fabric used in the shoe industry. Due to the weight of this product, a special device for holding down the narrow fabric and a reinforced tape take-off motor are used.

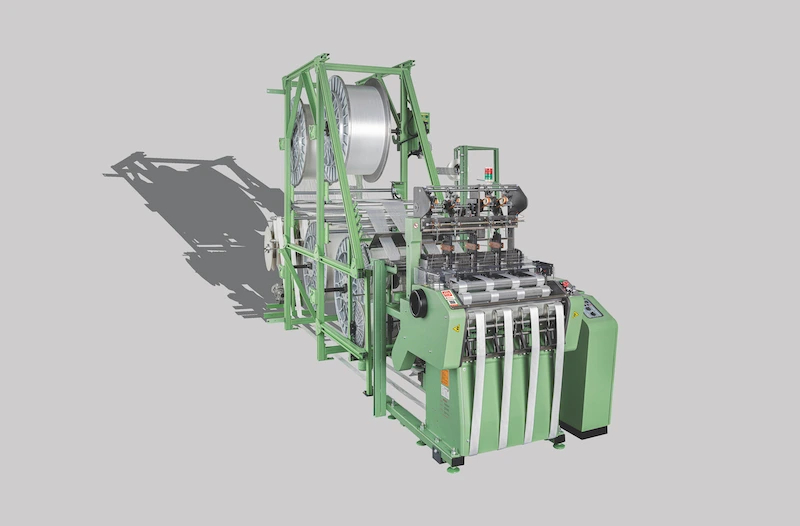

Another narrow fabric loom, the MD 2/130, will be on show at the booth of CREALET AG in Hall 6 at Booth B 306. The machine is designed for the production of medium-heavy webbing in the field of load securing and lifting equipment. Consequently, the MD 2/130 exhibited at ITMA has been equipped with the “system V” weaving system and can be used for production of narrow fabric widths ranging from 70 to 110 mm.

The MD 2/130 machine is equipped with the electronically controlled warp thread supply KAST ECR (Electronic Roper Control) from CREALET. This control system maintains a constant tensile force on the warp thread – no matter whether the warp beam is full or near depletion.

Measured values are recorded via strain gauges on a measuring roller, the mountings of which are manufactured using state-of-the-art 3D printing techniques. The braking system for the warp beam takes the familiar form of a braking system with a wrapped rope.

However, a new feature is a linear motor at the end of the rope, which is attached to the frame. The position of the linear sensor can be detected at any time with the aid of a Hall sensor, allowing the braking force of the rope to be varied. Closed-loop control takes place throughout the entire weaving process and thus leads demonstrably to excellent and uniform quality of the narrow fabric – from the first to the last metre.

The SETPOINT (target) values are extremely easy to adjust via a touch-display, where the tensile forces (ACTUAL values) are also displayed. Calibration of the entire closed-loop control is implemented via a very straightforward configuration menu in the controller.

Up to 6 devices can be combined with each other – depending on the number of warp beams to be regulated. With the aid of the USB interface it is possible to connect e.g. a laptop for improved visualisation of the tensile forces. The manufacturer can access the system via TeamViewer. This makes it possible to offer remote services or carry out training depending on the needs of the customer.

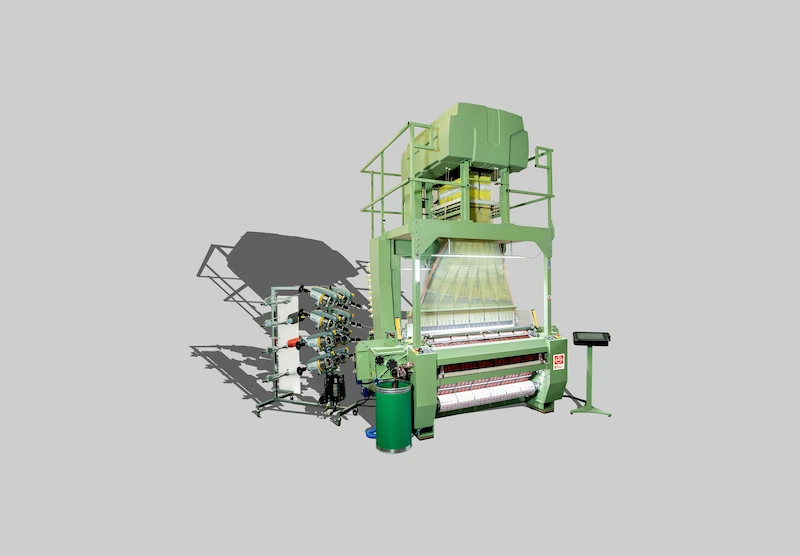

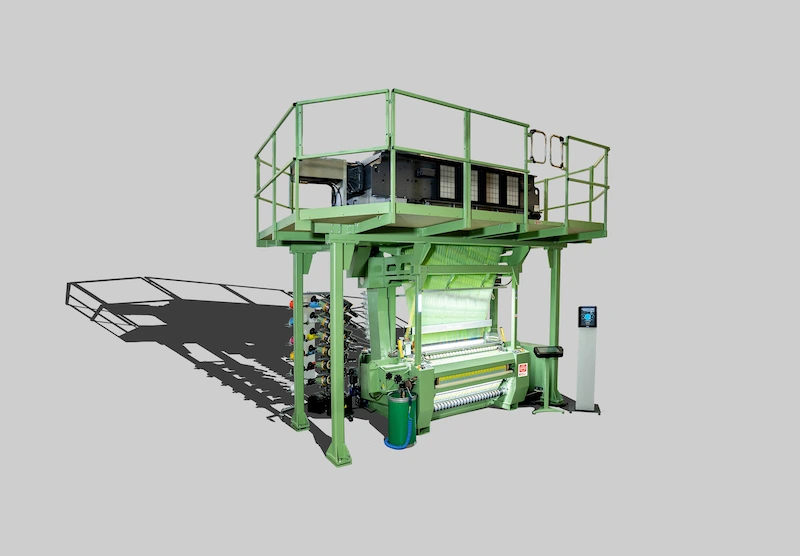

Label weaving system

The rapier weaving machine MÜGRIP® MBJ8v 1/1380 is a further development of the highly successful MBJ8 series introduced at ITMA 2019. The machine is designed for the production of labels also with designs in photo quality, fashionable tapes/ribbons, name tapes and lanyards with slit selvedges.

Slitting is performed with the hot-slitting system TC2. Of the 1536 functions of the Jacquard loom SPE3M, 1208 hooks are used for patterns. The warp consists of recycled polyester (PES-SET) with a fineness of 82 dtex, while the weft uses polyester filament with a fineness of 30 dtex and 250 dtex as well as an effect thread with a fineness of 1400 dtex. Generally speaking it is possible to process up to eight different weft threads, which are fed into the machine via a weft thread feeder of type IRO LUNA X3.

The rapier weaving machineMBJ8v LXL PRO 8192/6912T operates with an electronically controlled Jacquard loom from Stäubli of type LXL PRO, which offers 6912 functions. The machine produces labels with slit edges. Slitting is performed with the hot-slitting system TC2.

The individual control of each warp thread across the full fabric width enables not only pattern repeat widths of up to 120 cm, but also the production of individually coded labels. For the first time ever, a biodegradable polyester – PES-SET – with a fineness of 78 dtex is used in the warp. The weft uses polyester filaments with a fineness of 30 dtex and 250 dtex and an effect thread with a fineness of 1400 dtex. it is possible to process up to 12 different weft threads, which are fed into the machine via weft thread feeders of type IRO Star G2.

The high-performance narrow fabric loom NFMJ 80 8/42 768 MC is designed for the production of labels, name tapes and decorative ribbons with woven edges. The machine is based on the well proven NFM® platform and therefore offers significant advantages over predecessor models with needle weft insertion, on which labels with woven edges are also produced.

One of the innovations of the new machine is, for example, the direct weft needle drive, where a significant part count has been saved by doing away with the conventional belt drive system, which also results in reduced wear. The new and modified weft needle, which is manufactured using digital CNC technology, enables completely reliable placement of the binder thread in the enlarged weft thread triangle.

An additional slot in the weft needle prevents the weft thread from coming into contact with the warp threads of the upper shed, while at the same time also reducing the required tensile force on the weft thread. All these factors have a significant impact in terms of reducing the frequency of thread breakages. The developers have placed great importance on improving the infeed mechanisms for the warp, weft and binder threads.

The intake of the different thread systems has been revised and arranged more clearly. The torque-controlled tape winder ensures perfect winding density – from the smallest diameter to the largest. All of these measures make the machine easier to operate and allow the machine to be set up and adjusted more quickly and more easily – thereby helping to reduce costs in the weaving process.

The exhibition machine on show features a label product in which recycled polyester filament with a fineness of 82 dtex and recycled polyamide-6 monofilament with a fineness of 33 dtex are woven in the warp. The binder thread consists of polyamide-6 monofilament with a fineness of 22 dtex, and recycled polyester filament with a fineness of 55 dtex is used for the design. The product shown on the machine can be sewn as a label with a centrefold in e.g. garments.

Narrow knitting

The electronically controlled RR warp knitting loom DNBF/EL-800 is designed for the production of technical and high-performance products and is presented by Comez International s.r.l., a member of the Jakob Müller Group. The double needle bed machine operates with latch needles and offers a knitting gauge of 22 needles per inch (npi), eight electronically controlled bars and two bars for inclusion hooks retainers, sinkers.

The basic machine comprises two electronically controlled 3-roller feeds and an inverter for electronic speed control. At ITMA 2023 a knitted tape will be shown that is used in sports clothing. The product consists of recycled, textured polyester filament with a fineness of 167 dtex and has a stitch density of 18 stitches/cm.

Finishing

The combined fixation system for dyeing machines MFR 2C can be optionally equipped with a heat recovery unit in order to boost energy efficiency, and it is designed for finishing of light to medium-heavy, elastic and non-elastic tapes. The machine is designed for the fixing of dyes and for post-treatment in finishing.

It can be combined with Pad Steam, Pad Thermosol and Pad Steam Thermosol dyeing processes. The entire system consists of the tape feed, dyestuff application, infrared pre-dryer, combined chamber, eco washing tanks, finishing module, end dryer and tape take-off. The machine is offered with working widths of 200, 300, 400 and 600 mm as well as with multi-tape intake.

The modular design of the machine enables efficient integration of customer-specific requirements with tape content of 25, 50, 75 or 100 m. Analog or digital control of the pneumatic dancer rollers is possible. Gas heating or gas heating combined with steam fixing can be used as the heating system. An integrated washing system enables quick and easy changes of dye colour.

The covers can be opened pneumatically, which makes the entire process of cleaning the machine significantly easier. Production data can also be transmitted directly from the MFR 2C to mymuenet®. The system is presented as an individual module at the exhibition.