Interview with Mr. Per Thomas Fredriksen, Global Sales Director at Loxy

Loxy is a family-owned company with more than 50 years of experience in the textile industry. From the very beginning, we have had a strong focus on identifying and understanding customer needs. Our mission is to provide our customers with the highest quality customer service possible. It is part of the DNA of the company that has been passed down from generation to generation. Providing these added values to our customers has been key to our success in the textile industry.

KTJ: What is Loxy’s range of products? And specification?

We work closely with our customers to establish the textile qualities and characteristics they require. Our customers all have different needs and are looking for different solutions. If we begin the discussion with product numbers, we may miss the best solution. Conceptualizing the project first, then testing in our lab, and developing solutions is the Loxy way of working.

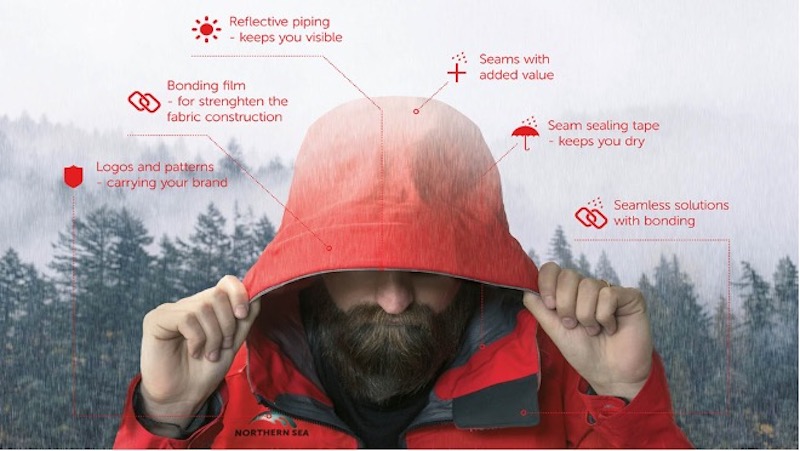

The below picture shows the many capabilities of Loxy’s products on one garment.

Loxy follows international standards and is certified with the following ISO standards: 9001, 14001, and 45001. An abbreviated list of the standards we are certified for includes:

- EN ISO 20471

- EN ISO 14116

- EN ISO 11611

- EN ISO 11612

- EN ISO 469

- EN ISO 3175

- EN ISO 1149-3

- EN ISO 6330

- EN ISO 15797

- ANSI 107

- UL

- NFPA 2112

- NFPA 1951

- NFPA 1971

- NFPA 1977

- Oeko-tex® standard 100 Class 1

- Oeko-tex® standard 100 Class 2

- Oeko-tex® standard 100 Class 3

- Bluesign

Norway is a country of extreme weather conditions, with its long coastline, mountains, northern fjords, cold winters and the sun that never sets in the summer. This environment has taught us that attention to detail is critical. We have learned to develop and deliver solutions at the highest level, in order to protect against all weather elements.

Loxy solutions are available in 5 segments:

Loxy® Rex, Reflective tapes from Loxy are offered in all the designs, shapes and sizes our customers in the apparel industry need. Our reflective tapes are made to be heat pressed or sewn on. We offer tapes for a variety of garments, including workwear, sportswear, leisurewear, and accessories.

Loxy® Seal, Seam sealing tapes are the most important component for waterproofing a garment. The adhesive tapes prevent humidity and water from reaching the inner layers of the garment, keeping the body dry. These tapes are also used in many medical products.

Loxy® Print, Print is your partner for creating stunning design aesthetics by means of heat transfer logos. Color, reflective, reflective-color, and FR versions are also offered. Compared to sewn logos, heat transfer logos are applied much quicker and customers like their contemporary look.

Loxy® Bonding, Thermoplastic polyurethane (TPU) hot melt films offer excellent adhesive strength. By using our bonding films on your garment, you provide stability to key areas and achieve stitch-free waterproofing.

Loxy® Film & Foils, We manufacture a wide range of advanced film materials. In fact, you have probably used Loxy products without even knowing it. We develop highly engineered-resins and polymers for customers around the world.

KTJ: How do you evaluate the workwear sector in general? You can add any number, export-import figures and statistics and … What are the pros and cons?

The workwear industry is incorporating more of the qualities of sportswear in terms of aesthetics and functionality. The design has become much more important in the workwear market. Additionally, there are now workwear collections for women. Designers from the sportswear industry are moving into the workwear industry, and vice versa.

This means that Loxy needs to constantly develop and adapt to the market. On top of this, we see that workwear is getting more and more technical and more standard is added to the garments. The regulations for substances and chemicals are getting more strict each year.

KTJ: How many percent of your products are export to international markets and how many percent use in local market? Where are your main export destinations and countries?

The Loxy head office is located in Halden, Norway, one hour from Oslo and close to the Swedish border. We have a small production center in Norway, while our large production lines are located in Sweden, Poland, and China. Some benefits of having production lines worldwide include being close to customers, options for securing raw materials, logistics advantages, and security of supply. Consequently, we are competitive in all regions of the world.

KTJ: Let us know about your latest products, research and development, new investment

Loxy is always listening to the market, our customers and end users. We also take our responsibility for sustainability seriously. This spring, we launched our newest development within seam sealing, bonding and film & foils – our biodegradable/eco-friendly solutions.

Another trend we see in the market is the demand for heat transfer reflective tapes that are both certified FR and industrial wash. Loxy has developed a product that meets these high standards and will launch in the second quarter of this year.

KTJ: Sustainability and recycling is an important subjects for textile manufacturers all around the world, what is Loxy sustainability policy and what you did do for this?

In our production, we use as many recycled raw materials as possible. We also have a strong focus on using only renewable electricity.

We receive a lot of interest from customers about sustainable reflective tapes. With today’s technology, options for recycling reflective tapes are very limited because the main ingredients are small glass beads. However, Loxy does have options for recycling the backing portion of reflective tape.

To be sustainable, Loxy believes the best solution is to use high-quality products that are durable for a long time. Low-durability products have to be replaced much too soon.

KTJ: How do you evaluate the EMEA region market?

We recognize that there is a lot of change occurring in the industry now. Production centers are shifting rapidly, and we believe that there is great potential for the EMEA to achieve growth in the apparel industry.