Interview with CEO Marcus Köhler, Power-Heat-Set GmbH

The perfect solution for every customer!

1. About power heat set company, history and success story.

The German company Power-Heat-Set GmbH supplies the carpet industry with machines and components for carpet yarn treatment. All of Power-Heat-Set’s equipment is manufactured by highly-qualified technicians at the German-based headquarters in Töging. There is a team of mechanics and technicians available worldwide for installations and service.

The US subsidiary in Dalton, Georgia, together with the sales agencies and representatives from all over the world, guarantee a quick response time. Power-Heat-Set’s Research & Development department in Töging continuously works on optimizations to bring the machines to the next level.

The team focuses on bringing advantages to the customer’s production process regarding quality, run ability, productivity, energy-saving and handling.

2. Let us know the range of machineries that you offer to the carpet and flooring industry?

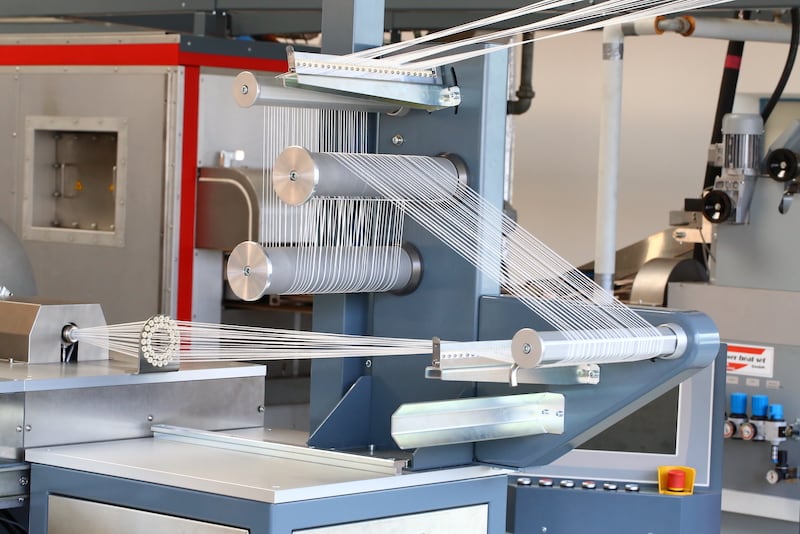

Power-Heat-Set’s machine portfolio currently offers two different machine types, namely GVA and HiPerSet. Each machine is available in different sizes.

The GVA offers the best flexibility and high performance for heat-setting carpet yarn with up to 96 ends. Due to its 6 channel configuration heat-setting of small lots on different belts, it is even possible to run different colors of the same yarn or straight set and frieze at the same time. The HiPerSet uses only one channel to heat set the yarn with overheated steam. Up to 84 ends can be processed at the same time.

Both systems, the GVA and the HiPerSet, are heat setting with overheated steam under atmospheric pressure. With the removal of obstructions to airflow, a high volume of climate circulation is achieved with relatively high compression allowing yarn to be heated quickly and thoroughly to the required heat set temperature. This improved airflow allows shorter dwell times.

3. Middle East (include Turkey) and Africa is an important market for carpet and flooring production, how do you evaluate carpet industry in this region. How many percent of your export come to this region? Tell us more about your export destinations.

Power-Heat-Set is supplying the carpet and carpet yarn industry all over the world. The Middle East is one of our most important markets and represents a considerable share of our overall exports. As per our experience this area is full of innovation and high-quality products in the carpet and carpet yarn industry and therefore we pay maximum attention to the needs and request of our customers in the Middle East.

Besides the Middle East we’re serving customers from almost all continents (apart from Antarctica) on a regular basis and are striving to grow our customer base daily.

4. You are more than 40 years in carpet yarn sector, what is a good carpet yarn specification?

This is a very good question and there’s no simple answer to it. A good carpet yarn specification is always that what the customer needs and we are dedicated in our job to make the production possible.

Throughout the decades we have made the experience that what the markets need is influenced by so many aspects, such as trends and fashion, the purpose of the yarn/carpet, innovation in materials and technology, raw material availability, raw material cost, production cost, etc.

Basically, the definition of what is a good carpet yarn specification is determined by the customers. Naturally, what is considered a good specification today might be already outdated in a couple of weeks.

5. How do you predict new investment in carpet yarn sector in 2021 after corona virus pandemic? How was last year and effect of pandemic?

Certainly, the Covid-19 pandemic was the “theme” of the last year. We certainly experienced a few quiet weeks from our customers due to plants being shut down, reduced production, quarantined operator staff, transport restrictions, raw material availability, etc., but all in all, considering the world situation we are satisfied with how the year 2020 went. We came through this year well and had the opportunity to finalize a couple of nice projects with some of our customers.

In our opinion the year 2021 will provide us with a lot of opportunities. Already in the last months of 2020 and up until now we have experienced increased activity in the industry, remarkably all over the world, but maybe mostly in the Middle East. There are a lot of projects out there and it seems like the industry is aching to get rid of Covid- 19 restrictions and come back to its old strength or even better to outperform it. There is obviously some backlog in investment and we’re doing everything to give our customers and partners the equipment and support that they need.

6. COVID 19 shows us we should rely more on sustainability and green products, how we can improve sustainability in the textile and carpet industry? What is power heat set sustainability policy?

You are right. “Sustainability” has been a key word for us already for a long time, but the Covid-19 pandemic has shown us all how much we depend on external factors. Therefore, the sustainability discussion is certainly gaining more momentum.

Power-Heat-Set’s sustainability policy is certainly affecting multiple areas, both internally as externally.

Internally we’re organizing our products and facilities to be most energy-efficient. E.g. we have covered our buildings with photovoltaics and are producing about 75% of the energy that we’re actually using in production.

Also, when it comes to the design of our products and equipment, “sustainability” is always on our minds. We try to use sustainable materials wherever possible and design our equipment to last for decades. Our customer base is expecting German engineering and quality and that’s what they get. The best evidence for this is that today our customers are still using machines that have been built and installed 20 years ago and still have a quality product giving them the opportunity to produce high-quality yarns.

Another very important topic is the energy-efficiency of our equipment. Throughout the years, our R&D team has worked with high priority and successfully to reduce the amount of energy that our equipment is consuming. If you compare Power-Heat-Set equipment from 20 years ago with today’s state-of-the-art equipment, you’ll realize that energy-consumption has been significantly minimized.

As per some customers’ feedback, they were able to reduce their energy consumption by even up to as much as70-80% in some instances. This helps not only our customers to save money, but it also obviously helps our environment.

Another highly relevant area is to design our machines and technology so that “sustainable materials” can be produced. The yarn and carpet industry is striving to become “greener” and to be more sustainable by inventing products (yarns) with a high sustainability factor. Examples are “recycling yarns” or yarns made from organic, renewable resources.

This is a very important focus for us and we’re working successfully with some of our customers to establish production of such yarns on our equipment. No matter whether it’s recycled PET bottles, recycled carpet yarn or yarn made from organic fiber, we are trying to finetune our process to cope with the sometimes very special requirements of the specific material to achieve the maximum yarn quality.

These are only some examples of sustainability projects or areas within Power-Heat-Set, but sustainability is a predominant guideline in our daily work.