Speed pays off

High-speed model RD 7/2-6 EN successful in the footwear, clothing and mattress sectors

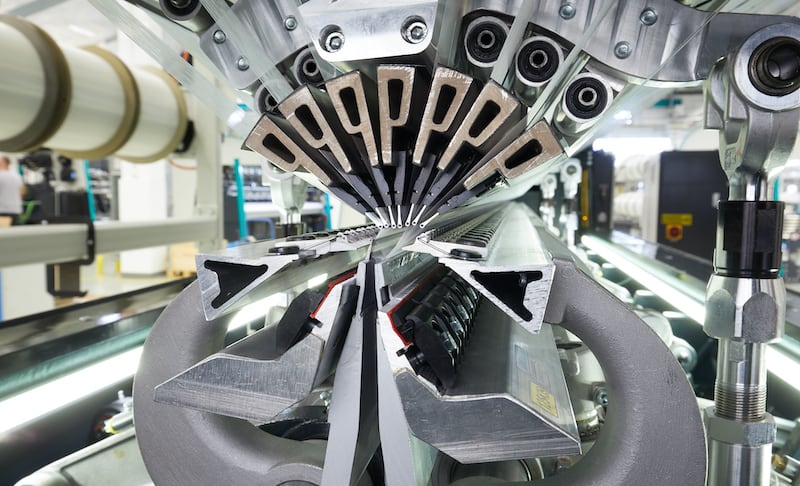

KARL MAYER continues to focus on speed in the double-needle bar raschel machine sector and is right to do so, as the RD 7/2-6 EN shows.

The of the RD-series produces high-quality 3D textiles with a trick plate distance of 2 mm to 6 mm. The medium-size articles cover the entire spectrum of common applications, such as shoe fabrics, mattress borders and clothing.

After adjusting and optimising the prototype, it was released for sale in 2019. The order books have been filling up ever since. “In the first half of 2020 alone, we have already delivered 75 machines of our new successful model,” explained Tang WenMing, Head of Double Needle Bar at KARL MAYER. “Customers in China, Taiwan and Korea particularly appreciate the flexible and highly productive machine, with which they are perfectly positioned in a volatile market environment.”

Compared to its established predecessor model – the RD 7/2-12 EN – the RD 7/2-6 EN offers up to 30 % higher speed using the same guide bar equipment. More output per machine also means space is used more efficiently and less manpower is required.

In addition, the design possibilities of the innovative RD series model are just right. The EN pattern drive in combination with a maximum shogging movement of one inch ensures variety. This allows the production of trendy fabrics with up to 12,000 stitch repeats, including most common designs produced on seven-bar RD machines.

The various fabric designs are possible without pattern disks but can be implemented at the same working speed as when using mechanical pattern carriers. By basing the EN- gear on the EL- one, the quality of the produced fabrics can be adapted to the requirements faster and easier. The RD 7/2-6 EN is offered in the gauges E 18, E 22 and E 24. The available working widths are 138” and 77”.