Modern draw frame machines offer a fantastic range of settings that can be adjusted to meet each spinners’ unique needs. But adjusting the break draft has still been difficult, unpredictable and very slow.

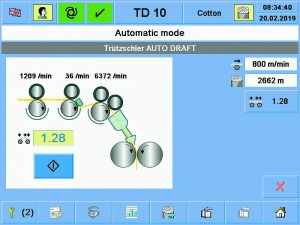

The AUTO DRAFT function from Truetzschler, which is part of our successful autoleveller draw frame TD 10, uses an innovative measuring method to automatically optimize the break draft during production conditions. And it takes less than two minutes.

For many decades, spinners have been wrestling with the awkward problem of how to adjust the break draft on the draw frame.

This is partly because adjusting the break draft involves changing a wide range of settings on the draw frame – and each setting needs to be adapted in line with every other setting. As a result, many spinners simply leave their break draft settings untouched because they don’t have time to interrupt their busy production schedule.

On top of this, there is currently no laboratory test or measured variable that provides clear information about the optimal break draft settings. Even fiber and draw frame manufacturers are only able to provide rough guidelines, which means spinners can only tell if their break draft settings are suitable when they inspect the finished yarn.

Many spinners try to adjust the break draft using the Coefficient of Variation (CV) value. But while low break drafts often improve sliver evenness, this approach can open up additional problems (as shown in the graphic below).

Setting the break draft too low can reduce yarn strength and elongation. And it can also increase the number of imperfections and have a negative effect on the running behavior and efficiency of the machines operating at later stages in the spinning process. This means optimization is only possible in the very long term, if at all.

Faster and better than anything else on the market

Our innovative AUTO DRAFT function provides a high-impact solution to this awkward problem in the production of carded ring yarns, including polyester. It uses a state-of-the-art measuring method to calculate the best possible break draft setting automatically – within real production conditions.

The method considers all fiber and sliver parameters, as well as the settings on the specific model of draw frame and the relevant external boundary conditions. The user can then choose whether to apply the recommended setting in the software of their machine.

AUTO DRAFT is able to identify the optimal break draft setting in less than two minutes. This accelerates the process of adjusting the break draft and creates meaningful clarity about how to optimize those adjustments. Put very simply: It is faster and better than everything else that is currently available on the market.

A massive range of attractive benefits

Our customers across the textile industry around the world are already benefitting from AUTO DRAFT, a feature in our autoleveller draw frame TD 10. The major advantages include:

• Optimal adjustment of the break draft – including selecting the best possible settings for new materials at the first attempt.

• Correct drafting distribution in the drafting system.

• Less adjustment and shorter process times.

• Better basic settings for the machine – which reduces the negative effects of sub-optimal machine

setting and provides a better, more uniform sliver quality.

• Reduction of costs related to quality control.

• Easy monitoring and adjustment of the machine settings when the quality of the raw material changes.

• And improvements at later stages in the production process.

How it works

When activated, the AUTO DRAFT function continuously changes the break draft from 1.00 to 1.95, and then measures the draft forces within the drafting system.

Conclusion

The AUTO DRAFT function is a truly game-changing technology for break draft optimization. It makes it possible to adjust the break draft quickly and easily, using an innovative and automatic method that operates within real production conditions – and that takes all relevant factors into consideration. In this way, it is enabling spinners to save time and money, while improving quality and making their processes more efficient. It’s a major breakthrough for the break draft. And it’s empowering Truetzschler’s customers worldwide to grab a valuable competitive advantage.

About Truetzschler:

The Truetzschler Group is a German textile machinery manufacturer headquartered in Moenchengladbach, Germany. The family business is divided into the business units Spinning, Nonwovens, Man-Made Fibers and Card Clothing. Machines, installations and accessories for spinning preparation, the nonwovens and man-made fiber industry are produced in nine locations worldwide.

In addition to four factories in Germany, Truetzschler has production sites in China (Shanghai, Jiaxing), India (Ahmedabad), USA (Charlotte) and Brazil (Curitiba) as well as a development location in Switzerland (Winterthur). The company has a worldwide service network with service companies and centres in all-important textile processing markets.