Trützschler Nonwovens recently began collaborating with the Italian textile machinery manufacturer Texnology S.r.l. Together, we have explored innovative needle-punching technologies. Now, we are joining forces to offer production lines for needle-punched nonwovens under the name T-SUPREMA.

Needled felts are the oldest nonwoven fabrics in the world. Thousands of years ago, people entangled animal hair with needles to create functional textiles.

Woolen felts were used for clothing to keep warm and dry, as well as for shoes, blankets, tents and decoration. Today, needle-punched nonwovens are indispensable in many technical applications.

The biggest areas include construction (e.g. geotextiles), air and liquid filtration, and automotive engineering (e.g. dampening and insulation covers). Other durable products like carpets, furniture and shoes also use felts.

The high adaptability of the needling and finishing processes, as well as the broad material base, result in a high number of different end products. Needle-punching lines are able to process

natural fibers (e.g. jute, hemp, cotton or wool), man-made fibers (e.g. PP or PET), performance fibers (e.g. PPS or Aramide), and mineral fibers (e.g. glass or basalt).

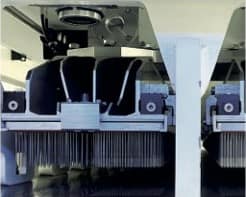

Needle-punching is a fairly simple technology. The first step is to form a carded or carded/crosslapped web. In a second step, thousands of hooked steel needles entangle the single fibers to form a strong, thick or thin nonwoven.

In most cases, a finishing process follows – such as heatsetting, calibration or surface smoothening. Finally, the nonwoven is wound into the finished roll.

The corresponding needle-punching lines are either inline configurations or offline solutions to decouple the fiber preparation and web forming from the needling, finishing and winding processes.

Trützschler Nonwovens contributes its many years of experience in fiber preparation and web forming to this cooperation with Texnology.

The team at Texnology is mainly responsible for the needle-punching process. It is a powerful example of how collaborative innovation projects are able to bring together uniquely broad application expertise

“With Texnology, we have an innovative and reliable partner at our side. The company already sets an important course in the field of needle-punching machines through excellent and patented solutions,” says Oliver Döring, Sales Director of Trützschler Nonwovens.

“Trützschler Nonwovens is returning to needle-punching solutions. In the partnership, we are able to serve this interesting market segment with precisely fitting production lines. With T-SUPREMA needle-punching becomes as easy as never before.”

Nicola and Paolo Olivo, owners of Texnology S.r.l., also see the joint activities as an opportunity: “Texnology has developed its own needling technology with patents and profound know-how.

Collaborating with a well-known, globalized company like Trützschler Nonwovens will significantly increase our target group.”

A first joint project has already been successfully completed, implemented and put into operation. Now, these two partners are building on this initial success to open up attractive opportunities for companies that manufacture needle-punched nonwovens worldwide.

Some of the main applications of needle-punched felts: