Non-woven textiles have a variety of applications in all industries around the world. Non-woven textiles are used in a variety of industries, including hospital clothing and equipment, respirators, diapers, sanitary pads and diapers, synthetic leather, automotive, geotextiles, agriculture, and home use.

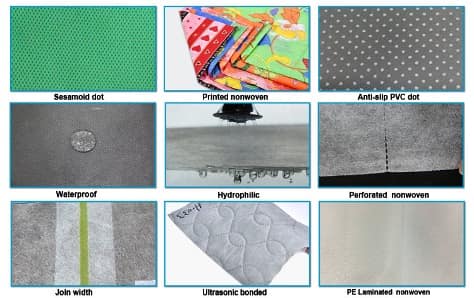

These textiles can be made to absorb moisture, be breathable, fire-resistant, heat and light insulation, be moldable, soft, stable, hard, and resistant to cuts, and also repel insects if necessary.

In recent years, due to the COVID pandemic and its effects on the lifestyle of the people of the world, the growth of the non-woven textile industry, especially for use in the production of absorbent health products (AHP) has been significant.

The non-woven industry needs to expand further in the future.

In the automotive industry, these textiles are used in car seats, sound and heat insulation, ceilings, wheel arches, and carpets because non-woven textiles are 30% lighter than conventional raw materials in the automotive industry.

In the construction industry, non-woven textiles are commonly used as a substitute for heavier raw materials such as steel in acoustic parts, floors and ceilings, roofs, window frame flashings, walls, and many more.

The global price of non-woven textiles has always grown significantly over the past 50 years, and the production of these textiles in all countries has rapidly increased. If we consider the average growth in the non-woven textile industry to be about 6 to 7 percent for the whole world, the growth rate of developing countries and Asian countries is about 10 percent, and the share of developed countries such as Germany, the USA, and Japan is about 3-4%.

The Middle East and North Africa region is at a disadvantage in terms of social and political conditions, which is why oil revenues have declined and governments have struggled to develop their industries. However, the non-woven fabric market in countries such as Iran, Türkiye, and Egypt has great potential for development. These countries are looking for opportunities for the growth of their industries in the future, and one of their goals is to develop their non-woven fabric industries so that they can use this opportunity to enter the non-woven fabric market.

This article describes the production, export, and domestic market consumption of each country in relation to the capacities and technologies of non-woven textile production.

Non-woven textiles

What is the situation of non-woven textiles in Iran?

The non-woven textile industry in Iran is an industry that has developed a lot in the last decade, and although it is still a young industry, a good future can be imagined for it. There are good companies in Iran’s non-woven industry that today try to enter global and regional markets to export their products.

In the division of different applications of non-woven fabrics in Iran, medical and hospital applications constitute about 5% of the total basket of non-woven textiles. For example, before the COVID outbreak, the annual production capacity of masks in Iran was about 120 to 200 million pieces, after which the daily production of 1.2 million masks has been reported by licensed industrial units. By comparing these figures, we will find that Iran’s usual nominal capacity has increased several times.

Of course, for domestic consumption, about 50 million masks are needed daily to combat air pollution and pandemics, and therefore the probability of per capita consumption of masks will increase compared to the years before the pandemic.

According to the information received from the General Department of Textile Industries of the Ministry of Mines of Iran, 37 units with a capacity of 43,000 tons are active in the production of non-woven fabrics.

Some of the famous companies in the field of non-woven textile production are Zarif Mosavar industrial group, Rezin Industrial Kian, Peyvande Jahan Pars, Bi-woven Gostar Jahan, Pars Dorsa, Plast Yazd, Bi-woven Kalardasht, Novin Alborz.

Spunbond fabrics

What is the situation of non-woven textiles in Türkiye?

Specialized textile exhibitions, especially specialized exhibitions of non-woven industries such as Hitex and Tuyap in Türkiye, create a very good opportunity to understand the market situation and also to identify the position of Turkish manufacturing companies, which can play a very important role in implementing market development strategies.

Türkiye needs to import petrochemicals or polyester fibers. Iran exports polymer materials and polyester fibers to Türkiye. Turkish investment in the production of non-woven textiles is several times that of Iran and is considered as one of the significant centers for the production of non-woven fabrics in the region.

According to official statistics, the capacity of non-woven textiles of Türkiye production doubled between 2009 and 2014 and experienced a 100% growth in this production volume between 2014 and 2019. The growth of the non-woven industry in Türkiye continues to grow.

The non-woven textile exports of Türkiye in the first half of 2018 increased by about 20.1%, reaching $ 898 million. The most exported products from January to June were non-woven fabrics.

The exports of these products have increased by 30.6% and their value is about $ 294 million. This group of products is about 32.7% of Turkish textile products.

Another non-woven fabric that has sold a lot is parachute fabric. Exports of this product have increased by 135.7% compared to last year.

Some of the famous non-woven fabric companies in Türkiye are Sonimak Makina Sanayi, Pusula Cizgi, Mogul Tekstil Sanayi, and NFS TEXTILE.

Non-woven fabrics

What is the situation of non-woven textiles in Egypt?

The Egyptian non-woven fabric industry enjoys the continued support of the Egyptian government and the European Union and has led to many structural changes and modernizations in the Egyptian textile industry. In 2008, the European Union invested € 80 million to support Egypt’s textile industry.

This has led to an increase in the number of small and medium-sized units that move towards production with quality and high capacity by investing and purchasing modern machinery.

Egypt is active in the production of PP non-woven textiles. These PP non-woven fabrics with good strength and quality have a weight of 10 to 200 grams per square meter, and a maximum width of 3.2 meters. Its annual production capacity is 3,000 tons of fabric and 10 million sets of surgical gowns. 70% of Egypt’s PP non-woven fabrics are exported worldwide. Its main markets are Europe, Africa, and the Middle East. Due to its proximity to the Suez Canal, Egypt has a good geographical location and it is easy for domestic and foreign customers to transport and deliver products on time.

Another PP non-woven textile is the production of SMS fabrics, which are used for insulated hospital clothes. This factory is designed with the highest ReicofiL4 technology and has a monthly production capacity of 500 tons for health and medical fabrics. They also produce Meltblown materials for surgical masks.

According to the Egyptian Ministry of Industry, there are 4,259 weaving, textile, and garment production units in the country, which account for about 26 percent of Egypt’s national industrial income and 24 percent of the country’s industrial exports.

Some of the most famous companies producing Egyptian non-woven fabrics are CTMC Non-woven CO. LTD and AL-AMAL Non-woven.

PP non-woven textiles

What machines are needed in the non-woven industry?

The non-woven textile industries in Iran, Türkiye, and Egypt started about thirty years ago and all modern machines are up to date with technology. The first Spunbond factory started in Iran in 1986, the first polyester products in Egypt in 2008, and the group of polypropylene and polyester production companies in Türkiye started in 1994.

The main equipment of the factory is as follows:

• The main unit includes feeder, extruder, spinning pump, extrusion calendar, electric motor, gearbox, and heater,

• The Meltblown preparation machines including feeders and extruders with microfilament production capability,

• Waste recycling production line including extruders, electric motors, gearboxes, and heaters.

• Other equipment including conveyors, dryers, twisting machines, computers and control devices,

• Laboratory equipment for quality control,

• Compressor to supply pneumatic air,

• Central ventilation and chiller for all devices.

Non-woven textile machinery

What is the role of the non-woven industry in the future?

The non-woven textiles with technical textures can change the future of the textile industry. The added value created by these products will be much higher than the conventional textile industry. Developed industrial and scientific countries have a great focus on this industry and seek to develop active university centers and attract interested young people in this field.

The International Textile Institute has announced that in 2021, the production and consumption of non-woven textiles in the Middle East for a few reasons are less than anywhere else in the world. These reasons are the existence of large households, low-income levels, and also the low growth of non-woven in the agricultural and geotextile industries. But soon the use of this type of goods and the increasing desire of people for them in the countries of the region will increase.

The production process of these textiles has no by-products, but the production waste can be reused as long as it is recycled and put back on the production line. At least 50% of the waste in the non-woven industry is recovered. Waste from other sources can also be used to feed this production system. In this way, they have a positive role in preserving the environment.

Participation in international exhibitions allows manufacturing companies in Iran, Türkiye, and Egypt to introduce their products to global and regional markets. So they are no longer limited to domestic markets. In this case, in selecting raw materials, production technology, supply of machinery, and even the selection of employees, they will consider the best.

Colorful non-woven