AUTHOR : Mehdi Oveisi – Design Consulting Associates

The background and the new orientation in environmentally friendly materials and production processes as an opportunity for the industry.

The best floor mats for cars should protect your vehicle’s floor from wear, dirt, and salt corrosion.

They should also adhere to the strict standards set by government regulatory agencies regarding the design and manufacture of auto floor mats. While original equipment manufacturers are expected to abide by these standards, non-OEM aftermarket manufacturers of car mats are not really obligated to adhere to such conditions. This can make choosing the best car floor mats especially tricky since you don’t want to put anything inside your car that can be a safety hazard. Helping you determine the best possible product to choose.

When it comes to automotive design, the car interior in particular will undergo fundamental change: Trends such as electro mobility, connectivity and car-sharing will completely redefine the use of vehicles. The car of the future will be fully networked and seamlessly integrated into daily life – the interior will become a multifunctional living and working space.

The automotive industry in Germany has spent the last few decades focusing only on margins, neglecting its leading role in environmental technology. Germany as a “country of blockers and brakemen”. No more cars with combustion engines will be sold by 2040 at the latest. That’s what governments and corporations want to commit to in Glasgow. The German government is probably not on board – and only one German manufacturer is either.

In the long term, the industry could face even more massive changes that could even threaten its very existence. The reason: the car with an internal combustion engine and even the entire individual transport in its current form may be discontinued models.

Due to significantly lowered market expectations for global vehicle production, Autoneum is lowering its revenue and earnings forecast for the full year 2021 as a result of bottlenecks in the supply chain of vehicle manufacturers, in particular the ongoing shortage of semiconductors.

Although end-customer demand remains strong in all regions, global vehicle production in the second half of 2021 is expected to be around 10% lower than in the first half due to bottlenecks in the vehicle manufacturers’ supply chain, especially for semiconductors.

The Corona crisis knows almost only losers, as the latest survey by the Ifo Institute shows. The automotive industry is particularly affected, but so are numerous supplier sectors. Now there is a threat of a massive expansion of short-time work.

They offers improved shock absorption, high rebound, and durability across a wide temperature rang.

The far-reaching restrictions on economic activity in the wake of the Corona crisis are also weighing heavily on demand in the auto industry. While U.S. carmakers have already reported significant declines in sales, German companies surveyed by the Ifo Institute also said that inventories of unsold cars had recently increased again at a faster rate. Accordingly, inventories rose twice as fast in March as in the previous month, while the shrinkage in order books continued to increase.

Much of what used to make vehicles desirable – impressive horsepower numbers, roaring engines, aerodynamic design, or even staggering luxury prices – no longer has the value it once did. Moreover, it’s not enough to simply equip fancy vehicle designs with intelligent control systems and electric motors. Rethinking does not simply mean retrofitting, but completely redesigning. And that applies not least to the vehicle interior.

There is no other part of a car that drivers see as often as the interior. But in the cars of tomorrow, vehicle interiors must be more than practical and pretty. New materials and construction concepts are designed above all to save weight.

Reduce weight with honeycomb designs

Automakers have been making lightweight strides using this technology in interior applications such as trunk-load floors, hatchbacks and sun shades. The honeycomb design is especially popular as it allows automakers to easily reduce weight within non-safety critical applications as opposed to the vehicle’s chassis applications. There is less risk of it negatively impacting its ability to absorb the impact of a crash, in addition to fewer safety restrictions.

The weight reduction approach is also extended to the entire interior and presented in an interior study called Performance 2.0. Instead of covering the base material with fabric as usual, the two components are joined to form a single component. This ensures lower costs and a reduction in weight.

To meet the EU’s C02 targets, every gram of vehicle weight counts. The body plays a major role in this, losing mass and volume thanks to new materials and construction techniques. But at some point, this will reach its limits. So the vehicle diet is also being extended to the interior.

Starting with sustainable materials

ECONYL® yarns makes its floor mats for the BMW i3, BMW iX and other models. this as a logical consequence of the growing environmental awareness at the Car industry. It is important to use recycled materials as the basis for these products. ECONYL® nylon, which is made from old fishing nets and other nylon waste, is a good fit for automotive industry needs.

Of course, any product that is made from recycled materials must look flawless and provide outstanding quality.

According to Giulio Bonazzi, however, companies are still hesitant to use recycled materials, particularly luxury brands. But this is slowly changing. Compared to petroleum-based nylons, manufacturing nylon from recycled materials produces 90 percent less CO2.

From fishing nets to sustainable yarns

Some of the old fishing nets have been recovered from the ocean, which Bonazzi says is the most “emotionalizing” aspect. “This is the main goal of The Healthy Seas, an NGO that Aquafil and two other partners set up in 2013 in order to promote awareness of the problem of abandoned fishing nets polluting the oceans.” But the majority of nets that Aquafil recycles come from fish farms around the world.

Aquafil collects the raw materials in two 15,000 square meter storehouses in Ljubljana, where they are cleaned and laced onto pallets. Other nylon waste such as old carpets, fabric remnants and plastic parts are also stored here. Then it is all taken to the chemical factory, where it is used to create brand-new ECONYL® nylon for use in eco-friendly products to promote environmental sustainability.

These companies are on the best way to sustainable use of material and environmentally friendly production and processing, Racemark International GmbH, Tarkett, Carpet manufacturer: Condor-Group, to name a few producers.

Hand in hand with this, the classic additions to the car’s interior are set in motion: seats swivel, and steering wheels and center consoles move. If desired, they can also take on new tasks: Instrument clusters with speedometer and tachometer, for example, are transformed into entertainment units and video conferencing systems. Tables become game consoles, center consoles become microwaves, and the insides of car doors become soft backrests. The carpets are made of 100% PP & PET tufted & needled or, in the high-end range, of leather alternatives & responsible wool.

All of this can be built with sustainability in mind: using lightweight materials with a good eco-balance, such as natural fibers, which also compensate for the high weight of the battery packs. They are already being used not only for seats and headrests or floor mates but also mixed with plastics for the door panels or instrument cover without any compromise on safety. Robust and easy-to-clean surfaces are important for car-sharing anyway, but they also help the environmental balance.

The value chain in the automotive industry is changing dramatically. The PwC study on the automotive industry mentioned at the beginning of this article assumes that vehicle manufacturers will sell significantly fewer vehicles in the coming years and will also have to contend with lower margins overall, while at the same time having to invest massively in electro mobility and autonomous control.

Among other things, the groups want to counteract this with alliances – BMW and Mercedes, for example, have announced cooperation on autonomous driving for 2019. In addition, the carmakers are planning to earn money not only from the sale of vehicles but also from other services – be it car sharing, entertainment, advertising or interior components that can be exchanged depending on the season, trend or occasion.

Car companies and designers are dreaming big, imagining interiors that will radically transform how people experience driving. If the “living room on wheels” is going to be shared, the components – from the screens we watch to the touch panels we use to choose the program – will need to be easy to clean, durable, and stylish.

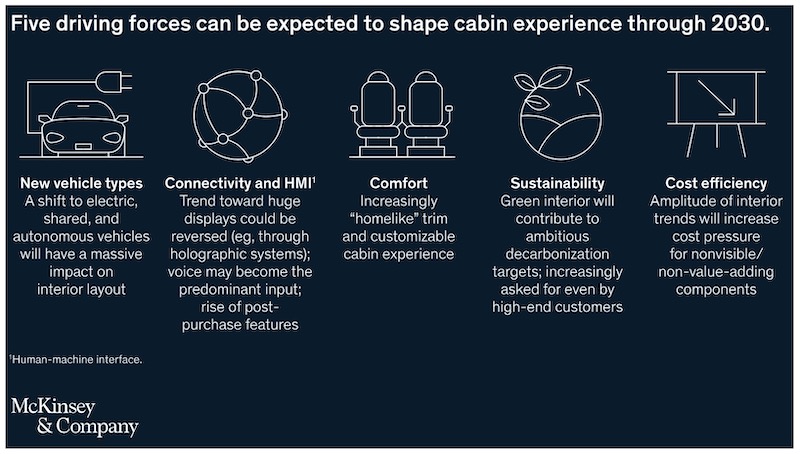

In the new automotive world, car interiors will take center stage as buyers focus on the cabin experience.

Source: McKinsey & Company, Fraunhofer IAO

New vehicle types, Electrification, shared, and autonomous will have a massive impact on interior layout

Connectivity and HMI, Trend towards huge displays could be reversed, eg, through holographic systems, Voice may become the predominant input; rise of post purchase features

Comfort, increasingly “homelike” trim and customizable cabin experience.

More space. The mechanics and architecture of a BEV’s powertrain allow for more interior space, much of which comes from flat floors and missing middle tunnels. That space can already be felt by passengers, but the opportunity for versatile usage and layouts—for example, lounge-like seating—has yet to be fully explored.

Surfaces and trim. As lighting continues to become as aesthetic as it is functional, surfaces and trim are becoming as functional as they are aesthetic with both intelligent features and a superior look and feel. Wood surfaces are now embedded with adaptive controls, and glass elements include haptic feedback functionality. In the future, seating could look and feel more like the Eames chair in a living room than the bucket seats we’ve become accustomed to. These will likely remain a niche applications in the next years, as indicated by our forecasted flat market development for seats and a slight decline for interior trim.

Sustainability, Customers are increasingly demanding environmental sustainability, and this sensibility extends to vehicle interiors as well. Two features in this category are helping OEMs win over customers and reduce their environmental impacts. Novel, eco-friendly materials. Responsibly sourced materials already make up a significant share of vehicle interiors.

The end of this decade could see cabins comprised of nearly 100 percent eco-friendly materials, which are also increasingly requested, even by high end customers, to fit individual lifestyle choices (for example, vegan interior offered by luxury car OEMs).

Lightweight materials. It’s not just body frames where lightweight materials are being applied. New materials for the vehicle’s interior are also a focus. Over the next several years, a growing share of interior materials could become lightweight to further support decarbonization efforts through lower consumption over the vehicle life cycle.

Cost efficiency, A more sophisticated understanding of which interior components bring value and which do not will be critical as differentiation is not free. Premium or excessive materials used in invisible or low-priority interior components are counterproductive to a smart interior strategy. A focus on two strategic areas will help ensure cost efficiency by reducing unnecessary spending.

[author title=”About Author: ” image=”https://kohantextilejournal.com/wp-content/uploads/2021/06/Mehdi-Oveisi-Textile-Designer.jpeg”] Mehdi Oveisi is (Master of Arts Textile Design) an experienced textile and product designer from various industries Textile and fashion brands (including Ploucquet Textiles and Sympatex Technologies) and the automotive industry (Racemark International) for high-quality transportation interiors, especially in the field of floor coverings, have been active in this sector for more than 16 years. [/author]