Author: Mr Anoop K. Sharma – Eltex Company

PROBLEMS DETECTING YARN BREAKS ON GRASS TUFTING MACHINES? ELTEX OF SWEDEN HAS THE SOLUTION

Introduction: Long and short pile artificial grass is produced on different types of tufting machines. The pile height can typically range from 5 to 70 millimetres. Depending on the pile height the artificial grass is used for different applications, ranging from golf greens to football fields.

During the tufting process, the yarns are pulled from the creel through plastic tubes by feeding rollers and, via guide eyelets, run through the eyes of the needles. The needles punch the yarn through the backing fabric, which is pulled gently through the tufting area. Then knives cut the loop at the right height to create the tufts, and the roll moves on to set the correct number of tufts per linear meter.

The typical speed of a tufting machine with a cut pile can be between 300 and 1000 RPM.

Yarn break or missing yarns on tufting machines

Due to defects in the yarn itself, excessive yarn tension, friction, problem in the creel, bent needles, yarn joints, bigger splices that do not pass through the backing fabric, dried yarn or other conditions, the yarn frequently breaks or other problems occur during the tufting process.

When a yarn fault occurs the machine must be stopped to repair the fault or else the product must be scrapped if the yarn break has gone unnoticed and the tufting is further processed.

There is a significant risk that an error in the artificial grass caused by a yarn fault that is not detected will only be seen when the grass is finally installed and unwanted stripes occur.

Yarn break detection by Eltex of Sweden

Luckily the above-mentioned yarn faults can be detected by the sensors manufactured by Eltex of Sweden, models EYE and EYE Compact/Compact II.

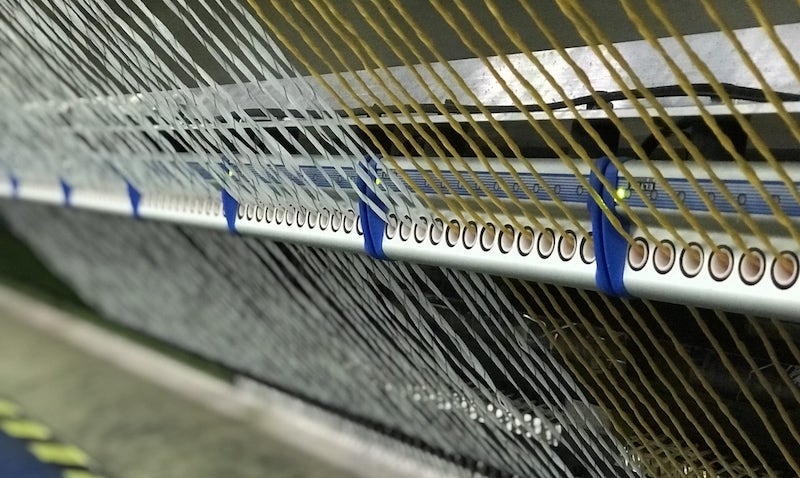

The Eltex EYE is a flexible system designed for yarn fault detection on grass tufting machines. The sensors usually fit between the feed rollers and the needles and are based on the well-proven piezoelectric principle.

The Eltex EYE monitors each yarn position in real-time and is designed to improve quality and efficiency by reducing mending and downtime. Furthermore, the unique compact design enables it to be used on machines with gauges as dense as 1/10 inch. All of the sensors’ data is processed by a master control unit, which provides stop and warning light indications to the user-friendly operator terminal in response to any detected yarn fault.

100% of tufting yarn faults are detected. The fact that the EYE system in most cases stops the machine before a fault has occurred in the tufted grass assures that there is no fault in the finished product in more than 95% of the cases. In some cases, a short fault in the tufted grass can not be avoided depending on where the yarn fault occurs and on the ramp downtime of the machine.

Advantages of EYE compact

• 100% of tufted yarns break and end-outs detected

• Detects when yarn falls out of the needle

• Less or no mending. Some carpets are not even possible to mend, so our system is a significant advantage

• More uptime and less waste of material

• Allows the operator to work on several machines simultaneously

• Increased efficiency

• More production due to less mending time.

• Networkable to a central database

• Faulty yarn is specifically identified, resulting in more up-time

• All events are logged in real-time and can be used for statistics and diagnostics

• Automatic addressing of all the system parts

• Easy to change the system configurations

• Fast learning of positions in use (No ON/OFF switches on the sensor)

• Simple cables with modular connectors

• Robust sensors in metal housings

• Sensor parameters can be set for different groups of yarns

• Ethernet, CAN Bus, Modbus (Available for OEM interface)

• Easy mounting of sensors.

Conclusion

It’s highly recommended to take full advantage of the technologies in terms of revenues, growth, quality improvement, machine efficiency, less maintenance, less waste of material and relief to the machine operator

We are proud to say that global artificial grass producers are Eltex’s customers.