The survey “Evolution and Impact of the Sustainable Technologies Project – 2022”, performed by RINA Consulting is part of the promotion activity carried out by ACIMIT for ITMA 2023, where sustainability will be one of the most relevant issues. The purpose of the study is to analyze the development of the Sustainable Technologies project over the years.

The Sustainable Technologies project was born in 2011 from an ACIMIT initiative, with the aim to monitor the textile industry equipment manufacturers’ engagement in the continuous improvement of their products, decreasing use phase consumptions and, consequently, the associated Carbon Footprint (CFP). Such improvements are monitored thanks to the Green Label tool which quantifies the related benefit.

In the framework of the project, nowadays encompassing 44 joined companies, 1433 Green Labels have been issued. An international certification body, i.e. RINA Services, has validated the process of issuing the Green Labels and the measurements the tool includes; moreover, every year the body verifies the procedure of parameters’ measuring and the operative conditions of the equipment under labelling on the 20% of the companies joining the project.

This study, representing the continuation of the survey started in 2015, has the aim to quantify the benefit associated to the project, expressed as overall CO2 avoided emissions, considering the equipment been modified from 2016 to date. Over the last few years, indeed, companies participating in the project have implemented technological innovations on their own labelled machines, resulting in an environmental and energy improvement. The technological areas in which the companies have mainly invested are software (19% of the enterprises), sensors and monitoring (18%) and mechanical components (16%).

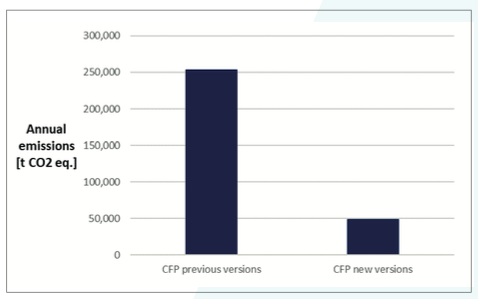

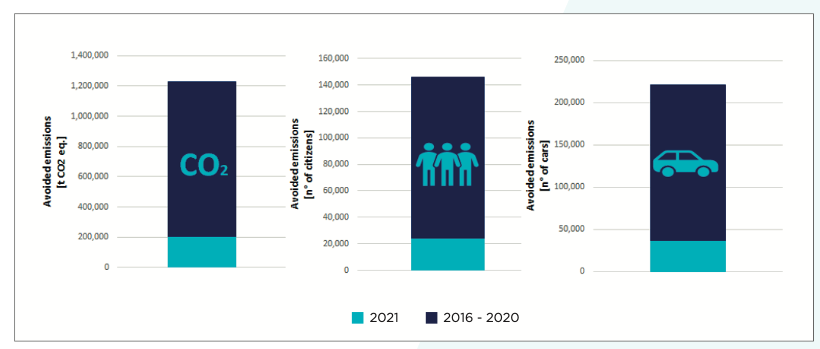

Starting from data included in the Green Label tool and information provided by the companies through a questionnaire (referred to 2021 values), 204,598 ton CO2 eq. of avoided emissions have been quantified thanks to the improvements on the equipment (Figure 1). Such reduction corresponds to the carbon dioxide emissions produced by 36,864 cars which travel for 35,000 km over a year (on average) or by 24,357 world citizens over a year*.

The overall impact of the project from 2016 to date has been evaluated, assuming a constant reduction trend of the emissions: in the last 6 years, the quantified avoided emissions are 1,227,587 ton CO2 eq., corresponding to 221,187 cars travelling for 35,000 km over a year (on average) or 146,141 world citizens over a year (Figure 2).

Figure 1 – Annual emissions generated by companies who implemented technological modifications on their equipment (comparison between old and new versions of the machines)

Figure 2 – Avoided emissions thanks to improvements on the machines, in terms of ton of CO2 eq., numbers of cars and of citizens (assessment for 2021 and estimation over the last years).

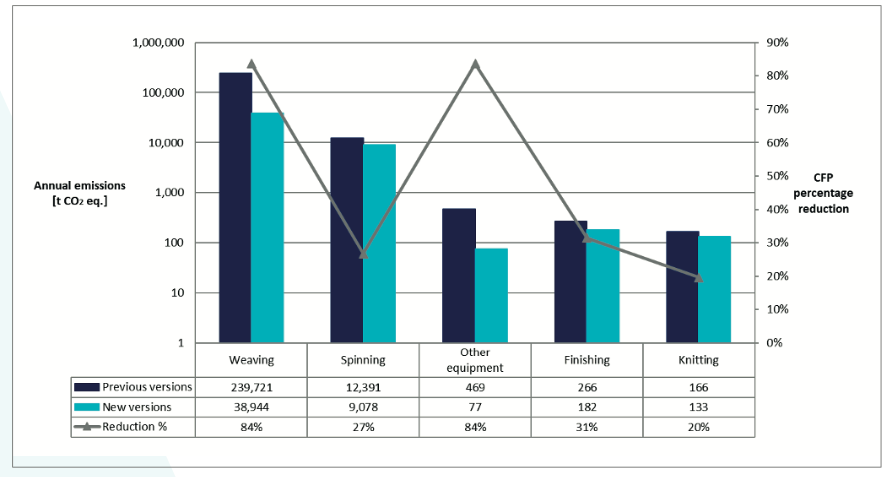

The achieved reduction has been calculated also exploring different companies related industrial sectors.

Figure 3 – Achieved CFP reduction, divided per sector (reference year: 2021)

Considering the reduction obtained by companies who introduced improvements on their equipment, potential values of reduction have been calculated per each sector, considering the possibility to extend the project to all company members and all their machinery produced. Based on this calculation, the annual emissions reduction could be increased up to 1,452,970 ton CO2 eq. (rather than 204,598 ton CO2 eq. per year), corresponding to the carbon dioxide emissions produced by 261,796 cars which travel for 35,000 km over a year (on average) or by 172,973 world citizens over a year.

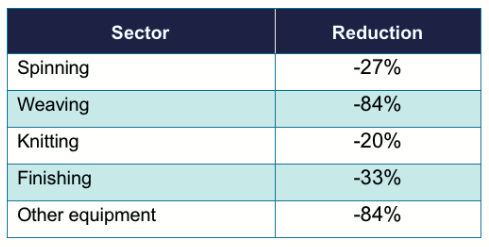

Technological innovations implemented on the equipment by the companies participating in the project result in several benefits, both on environmental impact (CO2 eq. emissions reduction for the machines during the use phase) than on economical point of view for the final users of the machines. The economical saving for end-users of textile equipment produced by ACIMIT members has been calculated through the information provided by the database of Green Label tool and using the annual quantity of materials used by the equipment. Since most of the improvements on the machines have interested a decrease in energy consumptions, the percentages of consumption and CFP reduction practically concur. Concerning the energy consumptions, reductions up to 84% have been observed (Table 1).

Table 1 – Economical savings for the End-users due to the Reduction of Energy Consumptions

These numbers prove the very potential of the Sustainable Technologies project, highlighting the obtained results up to now and the possibilities of an achievable further improvement for ACIMIT and associated members in the future.

Moreover, it is worth to remark that the ACIMIT Green Label has become sometimes an added value for the final end-users, who take advantage of this tool, for instance, to have economical benefit (e.g. easiness in gaining fundings from banks, authorization to import/buy machines using sustainable technologies) or to comply with requests/laws of governments, more and more driven towards the promotion of investments in eco-sustainable technologies (with the aim, indeed, to save water, chemicals and thermal energy).