Interview with Mr. Karl Gustaf Lundholm, Director of sales, Textile division, Eltex of Sweden

Please let us know more details about ELTEX Company, history and success story.

Eltex began life in Sweden more than 50 years ago when the company’s co-founders set about solving a problem that had created difficulties for the textile industries for as long as it had been mechanised. They wanted to find a way of detecting broken or missing weft yarn in a shuttle weaving machine.

The result was the development of the world’s first electronic weft stop motion sensor. The invention had its public debut at the ITMA exhibition in Hanover, Germany, in 1963, and Eltex was founded the following year in Sweden to manufacture these revolutionary products.

Today Eltex of Sweden is the leading supplier of yarn break sensors and yarn tension monitors in the world, supplying our products to many of the largest OEM textile machinery makers. Eltex Global holding: Our headquarters is based at Osby in Sweden. Our primary production facility, based in Ireland and the U.S. a branch, serves as the group’s sales and service facility for the American continent.

Let us know about services that you offer to textile and carpet and flooring sector?

Eltex is a world leader in yarn break sensors and yarn tension monitoring systems on textiles to improve the quality of the fabrics and carpets, artificial grass and make the overall manufacturing process much more efficient. Eltex of Sweden has been researching and developing technologies that enable weavers to increase output volumes and minimise errors. This has allowed manufacturers to increase production capacity and reduce waste.

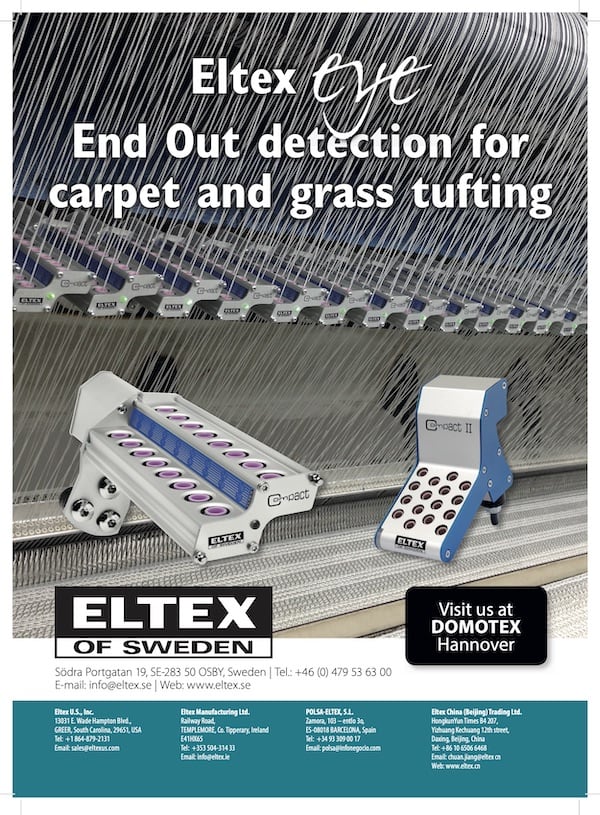

We offer our technology and applications of our sensors in different fields of the textile industry by monitoring every single yarn either in the form of yarn breakage or by monitoring tension and or controlling the yarn tension in real-time of single and multiple threads to improve quality, machine efficiency, cost efficiency, less waste of material, less maintenance and relief to the machine operator. On the tufting carpet and artificial grass side, EYE Compact sensors are designed for yarn fault detection on tufting machines.

It is designed to improve quality and efficiency BY REDUCING MENDING AND DOWN TIME. Eltex is contributing a significant role in the tufting carpet, artificial grass and yarn producing companies by offering intelligent sensors. The most apparent benefit is making sure that every single yarn is monitored. In addition, it is a great relief for the machine operator to know that the machine stops almost instantly when a yarn breakage occurs.

As a leader in yarn detectors sector, tell us more about your latest innovations and new technologies.

For 60 years, our yarn break sensors and yarn tension monitoring systems are enjoying a good reputation in the textile industry globally in more than 100 countries. After a tremendous global success with the EYE Compact for the tufting carpet industry, Eltex’s latest innovation is the EYE Compact II, unveiled at ITMA Barcelona in Spain last June (2019).

The product was developed in two years and is an evolution of Eltex’s original EYE Compact yarn break monitoring system. It is ideal for mounting on more modern graphics-driven machines, where space can be limited, for a 100% detection of every tufting yarn break and end out. EYE Compact II sensor technology operates at a critical stage in high-end carpet production, where everything comes together in the entire manufacturing process. The yarns and the carpet backing have already been produced and will be wasted if a fault is only identified later during the tufting stage.

We developed EyETM (tension monitoring for multiple yarn applications), detecting tension in each position on the creel & winder side of the heat set machine and warping creels to ensure that the correct tension is used in the process. With EyETM in a Heat-Set application, it will be guaranteed that the bobbins later used in the tufting process have the correct tension; it’s crucial to produce bobbins used in tufting with equal tension in the heat set process. If the tension is wrong, there is a significant risk it will create a fault in the tufted carpet. In the worse case, the fault is discovered only when the carpet is finished and dyed.

How Eltex equipment can help to tufting carpet companies to increase their productivity?

Digitalised solutions like ours, a stepping stone on the long road to Industry and the smart factory, are proving priceless for companies who have already embraced innovation. Moreover, it has been suggested that businesses that embrace digitalisation will enjoy long-term benefits, and, in many instances, these claims have already come to fruition. Eltex Yarn Expert (EYE) is a very flexible and versatile yarn detection system. The functions and features of the Control Units, sensors, and operator terminal are software controlled.

The carpet industry can take full advantage of the technologies of Eltex sensors in terms of revenues, growth, quality improvement, machine efficiency, less maintenance, waste material and relief to the machine operator. In addition, Eltex contributes a significant role in tufting carpet, artificial grass & yarn producing companies. Having fewer machine stops creates less maintenance and downtime.

This makes the machines wear less, and the operator can concentrate on other tasks around the machine. Fewer stops generate less wear and cut the electricity bills since the machine does not need to start many times. It has never been more crucial for companies to be cost-efficient. This all together shows that the EYE Compact system from Eltex saves money from day one.

By eliminating both production waste and machine downtime, manufacturers can boost their profitability and improve their sustainable footprint. This can be achieved by creating a quality product that generates less waste and uses resources more effectively.

We should rely more on sustainability and green products, how we can improve sustainability in textile and textile flooring industry?

Sustainability in the textile industry has become a debated issue due to the nature of the Industry. However, the great efforts made by our R & D department, our products are environmentally friendly because it helps to reduce waste of material. As mentioned under the previous point, by reducing both production waste and machine downtime, manufacturers can minimize their environmental footprint. This can be achieved by creating a quality product that generates less waste and uses resources more effectively.

How do you evaluate Tufting carpet sector in the USA and globally?

Eltex plays an essential role in the tufting carpet. The USA alone stand for 49% of the world’s carpet production, the second is western European countries with 27%, and 3rd is between Australia & Canada has approx. 8% and then the rest of the nations. Only in these three geographical areas, the total carpet production represents 84% of the global production.

We can say that + 70% of the global tufting carpets & artificial grass producers are users of Eltex sensors. At the moment, both grass and carpet tufting worldwide is in a strong position with a high demand for investment in new machines and other technology. On the carpet side, this is partly driven by a high demand on the US domestic market, and artificial grass seems to be used in an extended range of applications around the globe.

Middle east is an important region for carpet production, do you have export to this market?

The Middle East is the world’s fourth-largest carpet manufacturer after the U.S., Belgium and Holland, and the regional Industry is expected to grow between 10 -25 % over the next five years. We have started our marketing efforts, and we are in communications with some of the carpet producers in the region. We have recently expanded our marketing network for the middle east region and hope to get some good results. Now, we are being represented by M/S. Atag Export & import of Alexandria, Egypt for middle east region.

What is your schedule for participation at upcoming textile and flooring exhibitions?

We exhibit every year at Domotex in Hannover and look forward to be back to meet our customers in January 2022. We also had plans to exhibit at FloorTech, USA, but have unfortunately withdrawn because of the Corona situation.