Run Circles Around the Competition

Amid this global crisis, many market sectors and the businesses operating in them are facing significant challenges. The print industry has not escaped this downturn but, where possible, its resilient and resourceful members are looking for ways to remain productive and profitable.

One of the ways in which print service providers are continuing to operate during this turbulent time is to diversify their product portfolio, offering new applications within market sectors that have been impacted to a lesser degree, or many even be seeing or expecting growth this year.

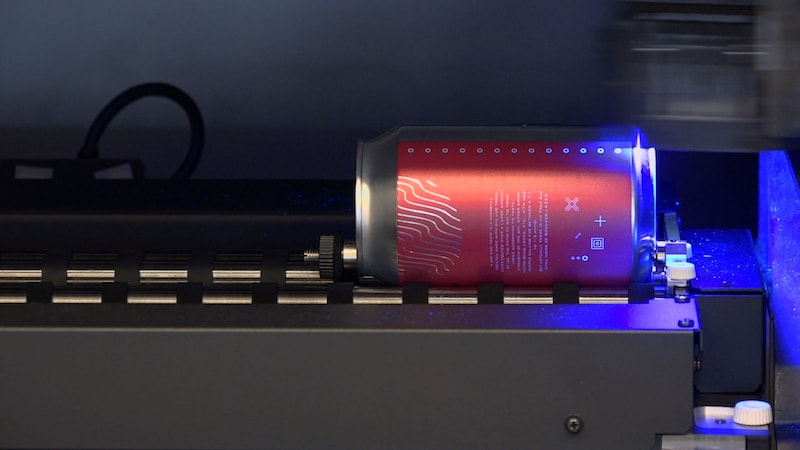

One such market is packaging and the step into this sector from sign and display is smaller than you think. The Mimaki’s Kebab option is a modular solution for Mimaki UV inkjet flatbed printers and enables printers to expand their product offering to include the decoration of cylindrical objects in an easy and effective way. It delivers creative freedom to decorate round surfaces in a wide variety of substrates and opens the doors to new application opportunities in different market segments and industries, including packaging and interior decoration.

Rens van Haren and Pim de Vries, Application Specialists at Mimaki Europe, offer an insight on the Kebab option – how it works from design to actual production, as well as the ‘dos and don’ts’ – and explain how it’s possible to achieve outstanding results that could be the key to meeting today’s market challenges.

Can you describe the Mimaki’s Kebab option?

Mimaki’s Kebab option is a separate module designed to expand Mimaki’s UV inkjet flatbed printers’ application capabilities. Equipped with rotary rollers, the module can be easily mounted on the table of the printer, enabling 360-degree direct printing on cylindrical objects, including glass bottles, aluminium containers, stainless steel tumblers, decorative candles and more.

This solution makes it possible and affordable for printer service providers to develop new, innovative product lines, as well as to produce on-demand original products in short or individual runs.

What Mimaki’s standalone printers are suited to be used in combination with the Kebab option?

Actually, there are different models of the Kebab option available. The original Kebab model is compatible with Mimaki’s flatbed UV printers UJF-3042HG and UJF-6042. The most recent models, namely the Kebab MkII and the Kebab MkIIL – which differs in size – are designed to be used in combination with the UJF-3042MkII and UJF-3042MkII EX, and with the UJF-6042MkII, UJF-7151 plus respectively.

What kind of three-dimensional objects can be printed with the Kebab option? Are there any limitations?

The Kebab option can be used to print on cylindrical objects, with diameters from 10mm up to 110mm and weight up to 2kg maximum. In terms of size, the small Kebab unit can print on objects with maximum width of 300mm, whereas the large Kebab unit can print on objects with a maximum width of 600mm.

This size and weight range encompasses a huge array of objects that can be decorated with this solution. As mentioned above, users could print onto cans, candles, glass containers, tumblers… the list goes on.

Of course, there are some limitations when it comes to printing with the Kebab option. It is not suitable for conical, oval and flat objects, as those shapes would hinder the rotational movement of the rotary rollers. In a similar vein, all those cylindrical objects featuring protruding parts, such as clips, handles, buttons, cannot be decorated using the Kebab option as they would not correctly follow the rotation, with the risks of blocking the printing or spoiling accurate results.

What market segments can be addressed with Mimaki’s Kebab option?

The Kebab option is an extremely versatile tool designed to fit the needs of different market segments. Arguably, the promotional market with branded items and customised gifts and accessories is the most obvious one. However, when it comes to decorating three-dimensional objects, there is a broad range of businesses and industries that could be involved.

In the first instance, the packaging industry – whose leading players are always looking for smart solutions that enable high-quality, cost-effective printing onto glass or plastic bottles, tin cans, cylindrical cardboard tubes and many other cylindrical objects in different materials. Likewise, the cosmetics industry, where creative applications such as customised lipstick cases, cosmetic tubes and jars, perfume bottles and so on are sought-after nowadays.

Another interesting, yet maybe less obvious market is interior decoration and home décor, with the demand for decorated furnishing accessories, such as candles, lamps, lamp sockets, soap dispensers and so on, is booming.

Another relevant example is the industrial sector, where items like drills, batteries, PVC tubes, as well as fire extinguishers can be easily branded and customised using the Kebab option.

What tools do you need to start using the Kebab option?

To start operating with the Kebab option, users should be equipped with a measuring tool, namely a ruler or a calliper, and a design software, such as Illustrator, which will enable them to create the design. Obviously, a suitable Mimaki printer is mandatory, as well as Mimaki’s RasterLink6 software. Depending on the application and on the properties of the object surface, a specific pre-treatment product, such as a primer allowing extra adhesion, could be needed as well.

How long does it take to print an object with the Kebab option?

The estimated time for a job with the Kebab option really depends on the combination of several parameters, such as the size of the item, the print specs and the design. However, to give an idea, you would need about two minutes to print a complete row of lipstick cases, whereas decorating a bottle of champagne with two-layer printing would require up to 50 minutes.

For more inspiration and information regards adding the Mimaki’s Kebab option and a host of new applications to your product offering, watch this video tutorial :