DiloGroup, leading supplier for complete needling lines will present its products and developments at CINTE Techtextil from 19 – 21 September in Hall E1, Booth D03.

In its 122 years of history, the company has always set new standards in regard to machine performance and efficiency. Innovative technologies like DI-LOUR, DI-LOOP and Hyperpunch have created new markets for the nonwovens industry and contributed to continuous growth. Examples of recent developments in our machinery are the 3-D Lofter and MicroPunch.

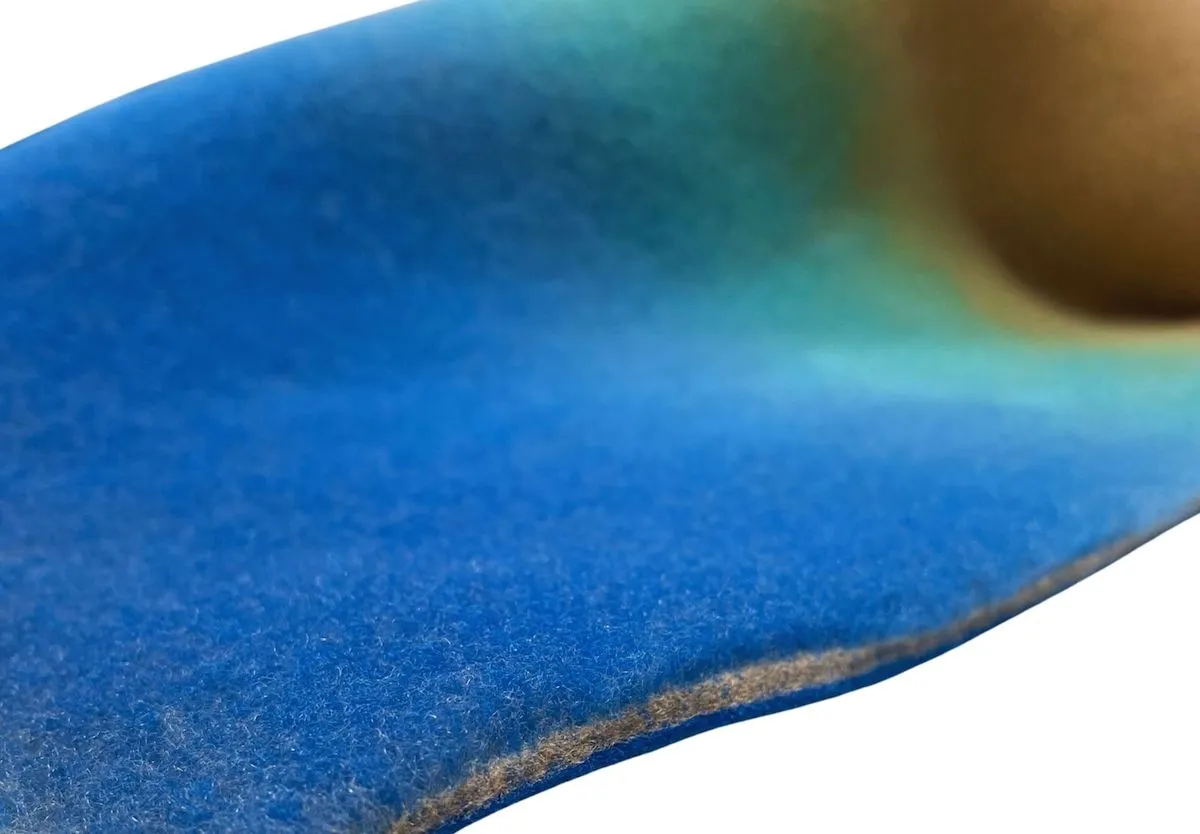

MicroPunch – Green Needling Technology for Lightweight Nonwovens

MicroPunch, the latest intensive needling technology in order to economically run products of 35 – 100 g. and over with throughput speeds up to ca. 160 m/min and at very high stitching densities of up to ca. 900 per cm2 in order to provide strength and abrasion resistance for hygiene and or technical nonwoven material.

The economics of needling apart from a raised productivity range is also the very low energy consumption per kg of product. Needling is a pure mechanical process with a high degree of efficiency and a rather low electrical power consumption. Since water is not necessary to consolidate the fleece, the high energy consumption while burning gas for the drying process is obsolete. The MicroPunch system is available for product development in the hygiene and medical sectors with the option of testing e.g. abrasion, haptic, tensile strength, air permeability and liquid absorption capacity.

Additive Manufacturing – 3D-Lofter/ISO-Feed

The 3D-Lofter comprises a series of individual web formers programmable to lay down additional fibre material. This either in an

1. IsoFeed function to improve the regularity of a flock matt to feed cards by up to ca. 4 – 5 % CV.

2. Reinforcement function of needled substrate used as car interior linings of deep moulded pieces in order to strengthen locations in the felt plain where stress or strain concentrations take place. Fibre savings can be achieved of approx. 30 – 40 %.

3. An additional feature of the 3D-Lofter is the widely enlarged patterning capability of needled felts for automotive applications or wall and floor coverings. 3D-Lofter in combination with the DI-LOUR process, which was also demonstrated by the DI-LOUR IV double structuring system, is offering a joint technology which is particularly interesting for lightweight moulded car velours.

At our Technical Research and Development Centres our customers have the opportunity to perform product development and test the various line configurations and special machinery equipment.