The complexity of military camouflage printing is immense. The wide-ranging requirements for the end products necessitate the use of a variety of technical textiles.

Camouflage printing is preliminary used in military applications to conceal or disguise soldiers, vehicles, or equipment in their surroundings. The patterns are mainly inspired by natural environments, such as woodland, desert, snow, or urban surroundings. A special feature is the IRR control which is required to ensure the camouflage effect not just in daylight but under the use of night vision devices in twilight and darkness of the night as well.

1. Definition: Technical Textiles

Technical textiles differ from conventional textiles due to their technical properties such as high strength, durability,heat re-sistance, waterproofness, fire resistance, protection against chemical substances, or mechanical stability. Technical textiles are used in various sectors, including construction, transportation, medical, sports, and industry. One important application is military camouflage printing!

2. What Is Camouflage Printing?

Camouflage printing refers to a specialized printing technique for textiles that aims to achieve a camouflaging effect. It is primarily used in military applications to conceal or disguise soldiers, vehicles, or equipment in their surroundings.

The patterns used in camouflage printing are often inspired by natural environments, such as woodland, desert, snow, or urban camouflage. Camouflage prints can also be used in other areas, such as hunting or outdoor sports, to blend in with nature and be less visible.

3. Camouflage Printing for the Military Sector

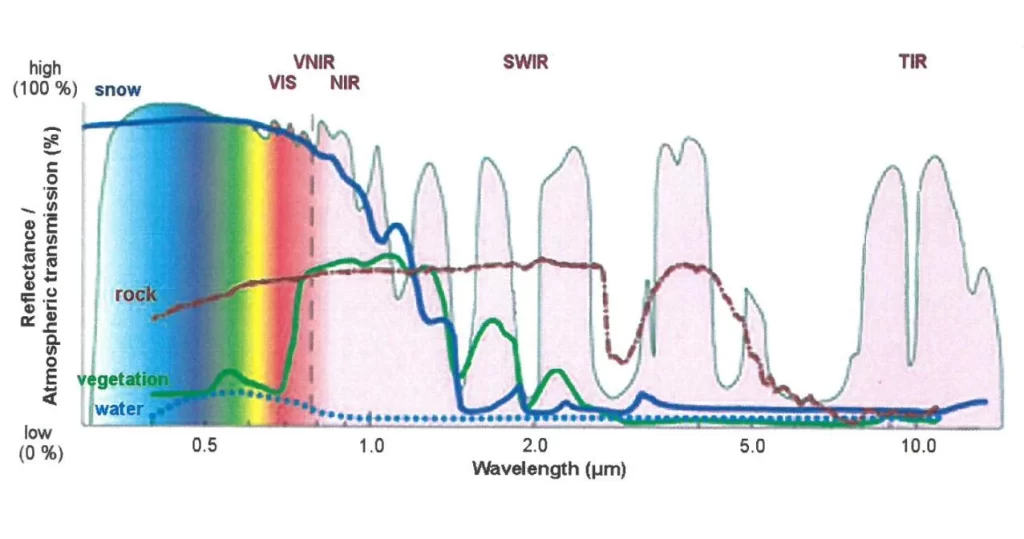

Here we are not only talking about the visible range, but also about the near infrared range with wavelengths of 700 – 1500 nm. Residual light amplifiers and infrared cameras operate in this range. It is assumed that more than 400 million linear meters of camouflage printed fabrics are consumed annually!

4. Wavelength Classification

UV (ULTRAVIOLET) RANGE: 10 – 400 nm

VISIBLE LIGHT: 400 – 700 nm

NEAR-INFRARED (IR-A / NIR): 700 – 1500 nm

MID-INFRARED (IR-B / MIR): 1500 – 4000 nm

FAR-INFRARED (IR-C / FIR): 4000 – 10000 nm

5. Camouflage Effect with the Use of Various Sensor Technologies

6. Infrared Signature of Different Materials

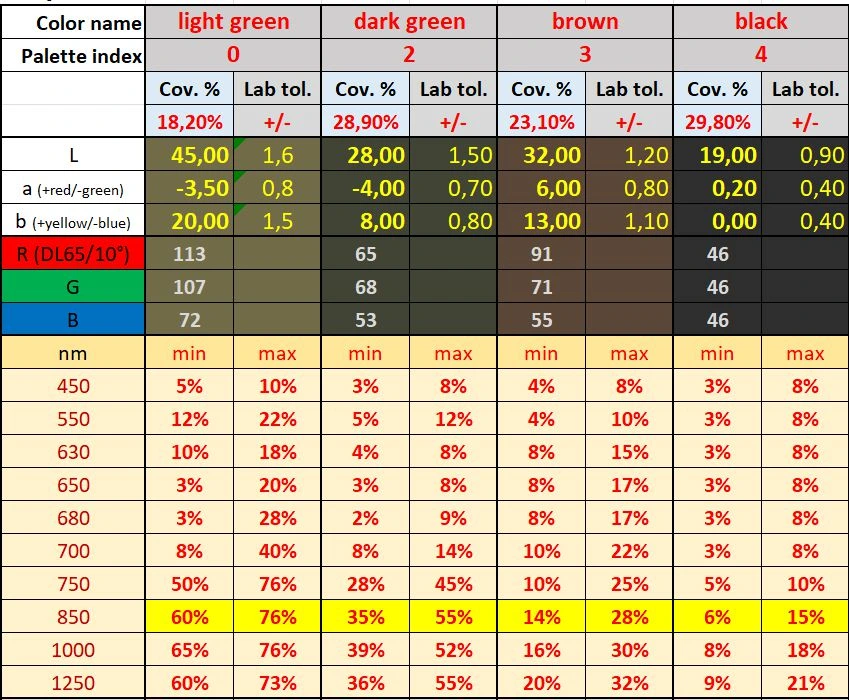

7. Specification of Colors and IRR Values

8. Camouflage Printing Requirments

- Accurate color matching according to L*a*b values

- Achievement of deep, saturated colors

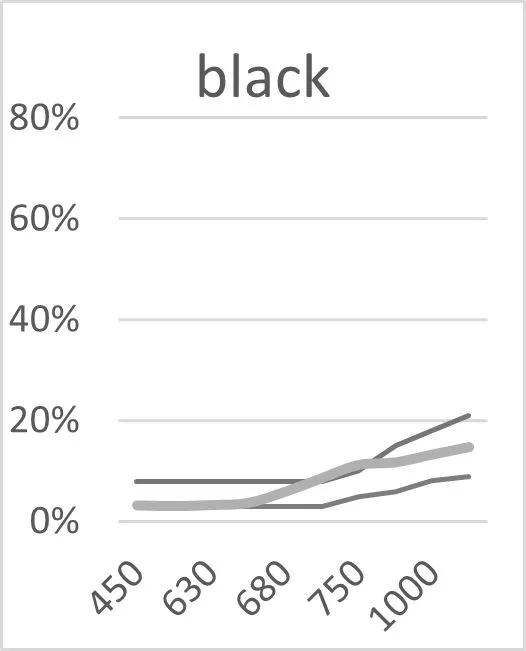

- IR reflectance must be in the min/max corridor for each color

- Fulfillment of highest fastness requirements

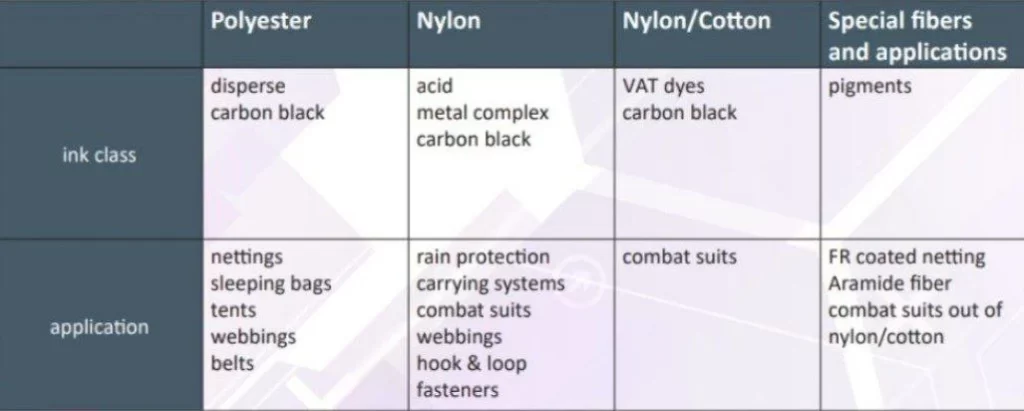

- Different dye classes depending on fiber type and substrate end use

9. Adjustment of IRR Values

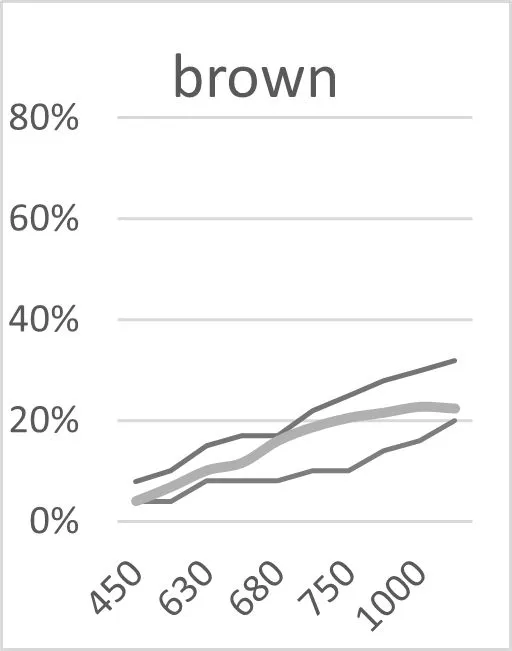

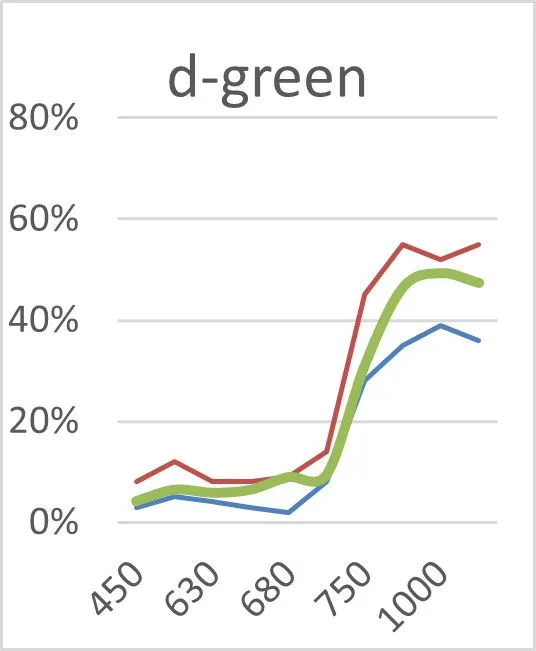

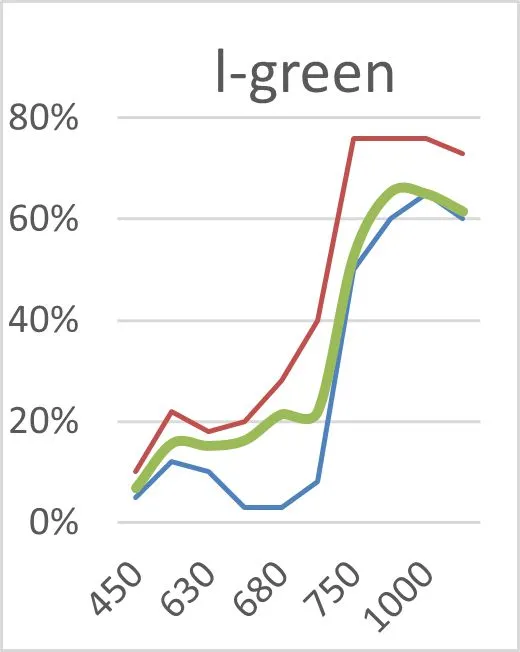

Each dye generates a specific infrared reflection (IRR). By combining different dyes, specific corridors can be matched. In many cases, different dye classes are used to determine the reflection (e.g. acid with pigment)

IR reflection of the print within the min./max. corridor

10. Difference Between “GOOD” and “BAD” IRR Signatures

11. Challenges and Solutions in Digital Camouflage Printing

Color depth and color gamut – highly concentrated special inks have been developed to address these issue

- Infrared corridors – special software tools have been developed to optimize the combination of inks with different IRR properties

- Lightfastness – selected dyes and fixing processes have been developed to ensure colorfastness

- Color consistency – automatic printhead calibration using drop mass measurement, maintaining a constant temperature of ink, and automated cleaning of individual printheads and color groups

- Combining different ink systems – in principle, all ink classes can be combined in digital printing

12. Colaris Printing and Its Position in The Camouflage Market

- COLARIS digital printing is a complementary technology to screen printing

- In future more and more special forces with special designs and colorways will be demanded. These tasks are impossible to do with conventional printing. Here the COLARIS process has its place and clear advantages

- Especially when it comes to product-, pattern- and color development – here digital printing is unbeatable. Small developers for camouflage products are looking for flexible print options without compromise in technical performance

- Low-budget customers are also in need of new developments and many design options must be offered

- Digital printing will have its place for small to mid-size orders as well as in product development. In future more and more camouflage items will be printed digitally

13. Advantages of Digital Camouflage Compared too Screen Printing

- No need for screens

- Unlimited pattern repeats

- Faster color and pattern development

- Relatively slower production speed (up to approximately 7 m/min for 1.6 m wide fabric)

- Not all dyes can be produced as inks for digital printing

14. Why The Future Belongs to Digital Camouflage Printing

- Inkjet has a much lower negative environmental impact in comparison to screen printing (color matching; color preparation; dye leftovers; system washing, …)

- Unlimited repeats and number of colors; no minimum quantity; fast sampling

- Less know-how in comparison to traditional printing is needed

- In future everything will be digital

15. Fibers, Classes of Dyes and Typical Applications