Report January 2023: zerowasteeurope.eu

Executive Summary

The current model of fast fashion is one of the main drivers of overconsumption, resource depletion, and social exploitation. The impact of the current business model based on fast fashion has revealed detrimental social and environmental impacts.

The European Union (EU) has published a Textiles Strategy laying out how it plans to tackle this issue. Until now global textile corporations have been unable to articulate a proper vision of what sustainable fashion systems could look like; think tanks such as the Ellen MacArthur Foundation have published proposals to address the topic, and non-governmental organisations have denounced the many inconsistencies and shortcomings of current performance and future plans.

As a result, there are a number of legislative initiatives aimed at restructuring the sector – mainly in the field of eco-design and waste management of textile products.

During the last decades, the use of cheap synthetic fibres has been fueling the current business model based on overproduction, combined with limited accountability for negative environmental and social impacts. This overproduction represents the biggest environmental impact of the fashion sector, way ahead of the impact of end-of-life management.

Yet, the legislative tools considered to date focus on products and waste, rather than on systemic factors or business models. Since overproduction is a systemic feature of a growth-dependent business model, the current legislative measures and the latest EU textiles strategy leave the most significant point unaddressed.

When looking at voluntary measures such as labels, which should help consumers to make sustainable choices, they are currently limited to toxicity, circularity, and transparency, but lack a systemic approach which could lead to fostering a desirable and sustainable business model.

The current push to increase the circularity of fashion products is a step in the right direction but insufficient to change the current business models. As a result, given the additional resources that are often required to produce quality and lasting products, the efforts of the sector to move towards sustainable production could paradoxically lead to a higher environmental impact if the model continues to be based on overproduction.

Given the novelty of the topic, there is not much literature, let alone consensus, as to what are the features of a sustainable, fair, and zero waste business model for textiles. Building on the best practices in the European market, we have identified 4 criteria which, when applied simultaneously, could be considered as key to identify what a virtuous business model that goes beyond circularity would look like. These are:

1. Design for physical and emotional durability;

2. Demand-driven production to phase out unsold and discounts;

3. Full supply chain transparency and traceability post-sale;

4. Extending the use-phase after first ownership.

Given the fact that this is the first study pointing at the difference between sustainable textile products and sustainable textile business models, and given the fact that textiles are also a relatively new field for policy intervention, more research and action would be needed in the particular fields of:

● Gains, costs, and externalities associated to a radical change of current business model to one that is fair, sustainable, and zero waste;

● Fashion and climate – in particular, looking at the carbon budget available for the sector as a way to inform future legislative steps;

● Fashion and biodiversity – studying the impact of fast fashion on current biodiversity decline;

● Identification of existing best practices from a business model perspective;

● Design policies to encourage the transition to, or/and creation of, new businesses following the

aforementioned criteria.

In the coming years, Zero Waste Europe intends to track the progress in the textiles world according to the classification above. In addition to this, we will further research what a virtuous business model looks like; and we will launch legislative and non-legislative actions to promote it.

Introduction

Each year, millions of tonnes of clothes are produced, worn, and thrown away. Every second, the equivalent of a rubbish truck load of clothes is burnt or buried in landfill. Global textiles production almost doubled between 2000 and 2015, while over the same period utilisation – i.e. the number of times an item of clothing is worn before it is thrown away – decreased by 36%. The business model resulting from combining overproduction with high environmental and social impact is known as fast fashion.

The consumption of clothing and footwear is expected to increase by 63% by 2030, from 62 million tonnes to 102 million tonnes despite the fact that the pace of global population growth is slowing down.

The current value of the fashion production is $3.3 trillion and it was producing around 2.1 billion tonnes of greenhouse gas (GHG) emissions in 2018 – 4% of the global total – using around 540 trillion litres of water and 1600 million tons of materials. On top of this, despite the increase in production and environmental impact, profit margins of the world’s leading apparel retailers decreased by an average of 40% from 2016 to 2019 due to ever lower prices and lost revenues coming from overstock, stockouts, and returns.

Almost 26 kg of textiles per inhabitant are consumed in Europe every year. 42% of these become waste and are eventually thrown away. In total, this amounts to 11 kg of clothes per person per year. Textile-to-textile recycling rates are around 1%, with most of the waste ending up in landfills or incinerators. The incredible volume of clothes production is enabled by cheap synthetic fibres – mostly polyester, which is found in over half of all textiles produced.

There is a clear correlation between the growth of polyester production and the growth of the fast-fashion industry.

Production of polyester has grown ninefold in the past 50 years, with this fibre being widely adopted in the fashion industry as a low-cost material. Polyester is cheap, costing half as much per kilo as cotton, and has cemented itself as the backbone of today’s throwaway fashion model. Synthetic fibres account for around 60% of textiles production with 70-90% of those being polyester. As a result, the average European consumer is buying 60% more clothing compared to 15 years ago, yet wearing it for increasingly less time.

Most recycled content in clothes today does not originate from textile waste but from packaging waste. Recycled polyester mostly comes from PET bottles which, instead of being recycled into bottles, are downcycled into fibres. Many clothing companies proudly label their apparel with “made with recycled plastic bottles” as if this would be a good thing. The fact is that they are downcycling and breaking the loop of a material which could stay in the loop for much longer before becoming waste. As a result, soft-drink companies struggle to meet their own recycled content targets.

Upcycling from fibres back to PET bottles does not yet exist at scale, and mechanical recycling of polyester-to-polyester happens at very low scale and for very concrete applications. Chemical recycling of synthetic fibres is hailed as a game changer but the technology is still in its infancy and pushed mainly by the chemical industry, since the fashion brands are yet to consider investing into this approach. It will take decades before chemical recycling can be used at scale for textiles.

Yet, the fashion industry is one of the major contributors of plastic microfibers entering our oceans and also one of the main greenwashers out there. Many certification labels and unchecked claims are used to increase sales and add to the environmental and social impact.

Last but not least, the fashion industry has also been singled out for human rights violations faced by garment workers, which include child labour, low wages, and health and safety issues.

10 years after the deadly collapse of the Rana Plaza building in Bangladesh, the situation has not improved, and serious industrial accidents and abuses remain commonplace.

The access to low cost labour, as well as the lack of accountability and sanctions along the textile value chain, are key enablers of overproduction, together with access to the cheap raw materials.

The pressure exerted by the big corporations maintains the producing countries in a form of status quo when it comes to social rights, and fuel social injustices.

Given the enormous environmental, social, and economic impact of this industry, and the lack of a short-term solution to these challenges, many actors are actively investigating possible solutions.

State of play

In 2022, the European Union published the EU Textiles Strategy, which states that:

“By 2030 textile products placed on the EU market are long-lived and recyclable, to a great extent made of recycled fibres, free of hazardous substances and produced in respect of social rights and the environment. Consumers benefit longer from high quality affordable textiles, fast fashion is out of fashion, and economically profitable re-use and repair services are widely available. In a competitive, resilient and innovative textiles sector, producers take responsibility for their products along the value chain, including when they become waste. The circular textiles ecosystem is thriving, driven by sufficient capacities for innovative fibre-to-fibre recycling, while the incineration and landfilling of textiles is reduced to the minimum.”

While these goals are valid and ambitious, the strategy falls short of suggesting measures to address the underlying issue at hand: the unsustainable business model of the industry.

In order to enable recycling at scale, the latest revision of the EU Waste Framework Directive (WFD) in 2018 included in art 12b the obligation for the EU member states to implement separate collection of textile waste by January 2025. However, it is unclear how this is to be implemented. Currently, most European countries have systems in place to collect clothes for reuse organised in a more or less formal setting. Finland passed a law in 2021 that requires municipalities to separately collect textiles already as of January 2023. Countries such as Italy started already in 2022; whereas, in many others, the roll-out of Extended Produced Responsibility (EPR) is on hold until the EU makes it compulsory. It is expected that EPR for textiles will be introduced as one of the targeted revisions of the WFD, currently scheduled for 2023.

In line with the EU Textiles Strategy, the EU Ecodesign for Sustainable Products Regulation is expected to bring about a digital product passport, which should allow for more transparency in today’s extremely opaque textile system, as well as design requirements for textiles placed on the European market.

In parallel, actors like the Ellen MacArthur Foundation have been facilitating processes with the textile industry to increase the circularity of fashion. Their value proposition is that circular models for fashion make economic sense and they might be in the interest of the big fashion industry:

“Circular business models for fashion, which allow companies to make revenue without making new clothes, represent a significant opportunity for new and better growth in the fashion industry. These business models, which include resale, rental, repairs and remaking, can provide considerable greenhouse gas savings, and could be worth USD 700 billion by 2030, making up 23% of the global fashion market.”

At the marketing level, many initiatives have been rolled out. On the production and marketing side, the amount of unfounded green claims by producers has increased, with many big brands presenting themselves as sustainable based on the use of recycled PET bottles, organic cotton, less chemicals, or fairtrade products.

On the collection side, some companies have been organising take-back schemes, but there is little to no information disclosed as to what is the fate of these textiles after they are collected.

For what concerns waste sorting, the technology exists to sort different materials and qualities, and there are functioning projects to automate the process. Hence, if EPR systems organise collection and sorting, the necessary technology exists to make it operational, yet it will take decades to build the necessary infrastructure.

When it comes to recycling, Europe hosts some recycling plants to recycle natural fibres – mostly from pre-consumer waste – and some synthetics, although most of the recycled content in use for textiles originates from fishing nets, carpets, and packaging.

Europe also hosts most of the innovation in the field of new materials for textiles, with some claiming to be fully recyclable and even carbon-negative.

Lastly, there are hopes for chemical recycling technologies to play a role in the recycling of both natural and synthetic fibres, the majority of which are currently not recyclable. However, it’s too early to know whether this solution is economically and/or technically feasible, as well as environmentally sensible.

If fast fashion is the problem… is product circularity the solution?

Most of the attention around the sustainability agenda of the fast fashion sector seems to focus on making the sector more circular in terms of product design. In this context, the vision from the Ellen MacArthur Foundation when it comes to creating a circular fashion industry is to ensure that products are:

● Used more – i.e. designed to last, with systems to enable repair and reuse, etc;

● Made to be made again – i.e. recyclable;

● Made from safe and recycled or renewable inputs;

Indeed, while these measures are enormously important to make the fashion industry more circular and sustainable on a product basis, they omit addressing two essential problems of the current system: the first one relates to the scope of the action; and the second one to the criteria applied.

1. When it comes to the scope of the intervention, the aforementioned approach is aligned with that taken by the current certifications schemes and labels, as well as the approach used by the EU Textile Strategy – in the sense they are focusing on identifying and promoting sustainable products. However, they do not target the business model that is the root cause of the product itself. Indeed, the biggest clothing brands have a line of products that are “conscious”, “made with recycled fibres” or with “organic cotton” and they get to be extensively promoted as if the whole brand would be sustainable. However, even if this was true for the few items that are labelled as such – which normally isn’t, given the aforementioned impacts of downcycling PET bottles to fibres, or the upstream environmental impact of organic cotton – the vast majority of the business continues with the traditional fast fashion unsustainable practices. In order to move from a model in which “the good” is the exception towards a model where “the good” is the norm, it is important to focus not only on improving the sustainability of some products, but also on changing the business model for the entire company. In other words, instead of optimising fast fashion by making it look more circular – which, in itself, continues to be an “unsustainable system” – a truly transformative approach should focus on changing the business model altogether and make it the new norm.

2. When it comes to the criteria, current efforts tackle circularity but leave aside important issues such as supply chain transparency, product traceability, sufficiency or resilience. In other words, closing the loop when it comes to textiles – but this applies to circularity in general – represents an important contribution to the reduction of emissions and waste generation, but there are many other factors which are critical to put the sector within planetary boundaries. Whilst the narrative continues to be to ’get rid of fast fashion’, most of the conversation in policy and academia settings focuses on closing the loop via collection and recycling.

For instance, the main policies considered by the EU Textile Strategy consist of increasing separate collection of textile waste, making producers pay for the collection and treatment of textile waste through EPR schemes, reducing microfibers release and developing chemical recycling to increase the extremely low levels of fibre-to-fibre/closed-loop recycling and recycled content of this waste stream. All of these initiatives are good and welcome, but insufficient, when the increase in circularity is vastly outpaced by the increase in production.

The priority should be to extend the lifetime of the product, but also making sure that the product is actually used longer to curb consumption – especially before planning infrastructure for waste that should not exist in the first place and will lock us into an incredibly wasteful model. Waste sorting and management infrastructure is needed but it is unclear the volumes we should plan for in a scenario of ever-increasing production and consumption.

There are high expectations on what the Digital Product Passport can bring about so that consumers can make educated decisions but, even if the initiative succeeds in providing transparency, there is no precedent as to how information alone can bring about a system change; and the gap between intention and action in consumer behaviour is a well-studied phenomenon.

All in all, the existing literature on the topic clearly defines the problem, offers some ideas on part of the solution, but provides no clear guidance on how to enable real systemic change that makes the textile sector compatible with planetary boundaries. The focus on high levels of recycling can be seen as sufficient, while they do not challenge the current fast fashion model. After all, there might be convergence as to what a circular textile product looks like – but there is no consensus as to what a sustainable, fair, and zero waste textile business model looks like; and, given the climate and resource crisis, circularity is far from enough.

Sustainable, fair, and zero waste by design

If one wants to come up with the right answers to the challenges posed by fast fashion, it is important to ask the right questions. Is the problem with fast fashion mainly related to products or to business models? In other words, can a fast fashion company produce sustainable products and still continue to run a fast fashion model?

Looking at current mainstream practices, one could imagine that it is possible to produce more sustainable and fair textile products and still continue to run a fast fashion business based on overproduction. Paying fair salaries to workers and using toxic-free, sustainable materials will certainly increase the price of goods, which can make fast fashion less profitable; but is this enough of an incentive to change the current business model that is at the root of the fast fashion problem? Which volumes of sustainable and fair fashion items are necessary in order to overturn the fast fashion business model?

There is no such thing as a sustainable textile product without a sustainable textile business model.

It is indeed important to have increasingly more sustainable textile products, and policies to increase their numbers must be supported. However, in order for them to thrive and become mainstream, they need sustainable fashion business models around them. On their own, sustainable products will always lose to fast fashion. Therefore, today’s focus on product ecodesign and end-of-life treatment are unlikely to succeed in overturning the current system.

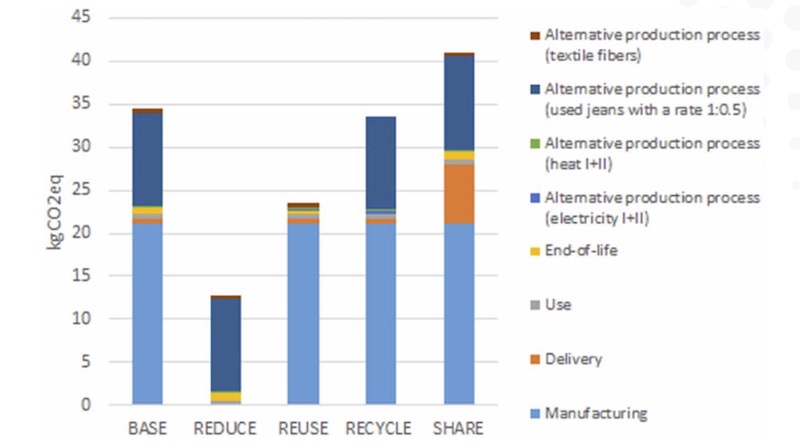

Research shows that circularity is a very important component of a sustainable business model but, interestingly, most of the gains from an environmental perspective are obtained not by closing the material loop but rather by avoiding production (see reduce option in the graph below).

Fig. 1: Global warming potential of different options for a pair of jeans

According to existing literature, the best option from an environmental impact perspective is to extend the use of materials and avoid purchasing new ones (reduce). The second-best option is to reuse someone else’s clothes (reuse), hence, reducing the primary manufacturing of one product albeit risking a rebound effect by replacing the garment of the donor. The third option consists in transforming reuse products into new materials, thereby decreasing the use of primary raw materials (recycling); and the fourth is collaborative consumption, which intensifies the utility rate of a product (sharing) also known as Product-as-a-Service (PaaS).

Whether recycling is better than sharing depends very much on the assumptions related to how much transport is needed to rent the product or how intense the emissions associated with production or recycling are (i.e. cotton mechanical recycling has very different emissions comparing to polyester depolymerisation); as well as the overall recyclability of the garment (i.e. jeans made of 100% cotton are a lot more recyclable than jeans containing elastane).

Also, whether reduce performs better than reuse very much depends on whether the extended use stage of clothes replaces primary production or slows down consumption cycles. Extended use does not automatically mean that the user’s collection of clothes remains the same, nor does re-selling automatically lead to increased use time; instead, it may provoke a rebound effect – i.e. people buying extra clothes from secondhand shops simply because of the low price.

However, with the current research at hand, emissions and rebound risks tend to be substantially smaller for reduce and reuse than for recycling and sharing. Still, the option of reducing production via longer use times clearly stands out as the preferred one.

Sustainability

When looking at overall sustainability and reducing the global warming potential of every product, it is important to ensure that the production of textiles doesn’t exceed a certain carbon budget. In this sense, and given the EU commitment to the Paris agreement, the minimum that policy should require from the textile sector is that it projects its production within a certain carbon budget that is compatible with staying within 1.5 Celsius degree warming.

Current estimations accredit already 6-10% of global warming to the textiles sector.

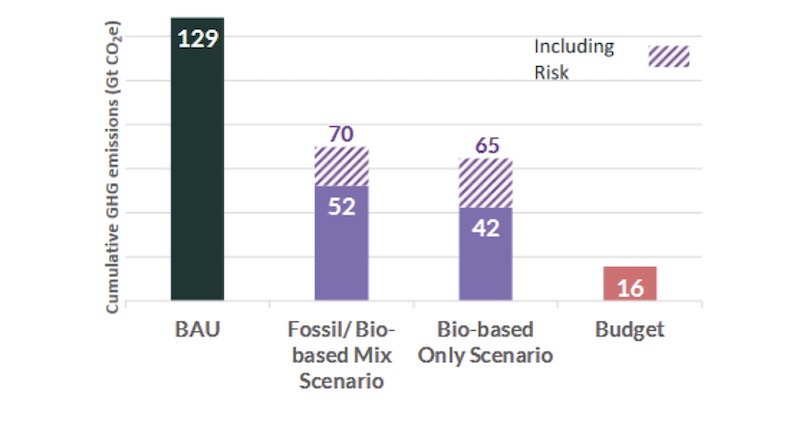

The latest research shows that plastic – the most commonly used material for textiles – is projected to overuse the carbon budget available for the sector by 5 times even in the scenario of maximum material circularity and decarbonisation (see Figure 2). The foreseen emissions of BAU for plastic (129 Gt), are higher than those budgeted to the steel, iron, aluminium, cement, and concrete sectors. Given the large amount of fossil-based synthetic fibres in textiles, it is clear that the only sustainable future for textiles needs to include a radical reduction of material use, coming on top of optimised design, collection, recycling and decarbonisation.

Fig. 2: Plastic decarbonisation scenarios until 2050

The current business model for the textiles industry is almost entirely supply-based. The circa 100 billion garments produced every year are not meant to satisfy the consumer demand – but rather serve a business model based on overproduction, sales, and huge amounts of unsold goods, much of which end up as waste and unnecessary emissions. However, throughout the course of human history, clothes production has always been demand-driven, with the relatively recent change to supply-based sales being one of the main reasons for its current unsustainability. With the current supply-led business model, it is impossible for the textile industry to stay within the available carbon budget for the sector. A shift towards production-on-demand is therefore critical.

Fairness

There is no fairness without transparency. A fair business model should be capable to trace back suppliers, materials, and processes across the whole supply chain in order to ensure that not only no child labour or any form of slavery and exploitation is used, but also that proper working conditions and health and safety measures are implemented. A fair business model should also ensure living wages while moving away from extractive and exploitative practices.

Zero waste

A zero waste business model goes well beyond design for circularity and includes, as a critical aspect, the durability of the design so that the garment never goes out of fashion. This means that perceived obsolescence should be as targeted as planned obsolescence, so that items that are fully functional can continue to be used for as long as the item lasts and not be dependent on trends.

Criteria for sustainable, fair, zero waste textile businesses

Many companies have identified both the contradictions of the current system and the limitations of focusing only on the product design and its circularity. As a result, there are bits and pieces of this new business model out there, but there is no blueprint as to what it looks like at scale. Likewise, currently there is no potential roadmap for a traditional textile industry to move away from fast fashion and into a business model that is sustainable and fair by design.

In other words, if one was to set up a textile company that would be sustainable, fair, and zero waste by design, what criteria would need to be met?

This is an attempt to bridge this gap and propose a way to identify and promote sustainable, fair, zero waste business models for the textiles industry.

The 4 criteria that need to be met simultaneously in order to qualify as such a model are:

1. Design for physical and emotional durability

The fashion industry should design garments that are both technically capable of enduring intensive use and many washing cycles – physical durability – as well as being able to live through trends and, thus, not going out of fashion – emotional durability – and be recyclable at the end of its life.

For instance, the recent revival of trends from the 90s will likely be a thing of the past soon, and the use of those items will go down even if, technically, there is nothing wrong with them. Instead, durability of design strives for timeless styles and modifiable patterns – while still having room for options and tips for personalisation to let people express themselves through clothes (one of the main drivers behind fashion).

2. Demand-driven production – design out unsolds and discounts

According to existing research, between 10% and 60% of all that is produced is never sold or is sold at discounted prices; and between 20% and 30% of what is sold online is returned and rarely put back on sale. In order to address the root cause of overproduction, it is key to change the business model from a supply- to a demand-driven one.

Producing on demand is a very effective way to design out unsolds and also change the cost structure of the business. It also allows for greater personalisation of styles and patterns in line with the taste of the consumer.

3. Full supply chain transparency and traceability post-sale

A sustainable business model is capable of guaranteeing the quality and fairness of all its products and services, and this can only be achieved if the company knows where components are sourced and how they were produced, as well as the fate of garments downstream and beyond.

Endless supply chains blur responsibility and make transparency harder. Shorter, more local supply chains allow us to connect the consumer to the producer and help build the emotional link between the individual and the garment, which helps to fight the current disposability mindset. It also allows for the creation of secondary raw material markets so that recycled content and used fibres are effectively used for new clothes.

Hence, potential consequence of increasing transparency will be to rethink where production takes place, how it takes place, and provide opportunities for connecting the consumer and the producer, thereby increasing brand fidelity. Child and labour exploitation, as well as the use of toxic products and additives, will be a lot more difficult to hide, with the likely consequence of resorting to materials and products produced closer to the consumer.

4. Extending the use-phase after first ownership

The company has a system to take-back, repair, redye, remodel and/or recycle its own clothes so that, when reuse and repair are no longer an option, the fibres can go back to the producer.

The company encourages mechanisms that allow for their clothes to be reused over and over again – be it with own initiatives to rebuy, collect, and resell; or by supporting clothes libraries, charities, and any other option which gives an extra life to the used clothes.

Next steps

Fashion is a relatively new field for policy intervention and more research will be needed in the particular fields of:

● Gains, costs, and externalities associated to a radical change of current business model to one that is fair, sustainable, and zero waste;

● Fashion and climate – in particular, by looking at the carbon budget available for the sector as a way to inform future legislative steps and make textile the first sector truly linking the circular economy agenda with the climate one;

● Fashion and biodiversity – studying the impact of fast fashion on current biodiversity decline;

● Identification of existing best practices from a business model perspective, Investigate how demand driven production can work in practice;

● Design policies to encourage the transition to, or/and creation of, new businesses following these criteria

Conclusion

The fast fashion sector is in the spotlight because of its negative social, economic, and environmental impact, but also has the big potential to reverse the current trend. As a result, there are a number of legislative initiatives aimed at (re)structuring the sector, mainly in the fields of eco-design and waste management of textile products.

However, the biggest environmental impact of fast fashion comes from the current overproduction model, which has replaced the traditional tailored production on demand. The legislative tools considered so far focus on products and not on systems or business models. Since overproduction is a systemic feature of a concrete business model, the current approach leaves this point unaddressed.

This approach to make textile products fair and sustainable is necessary, but insufficient, to change the current business models.

Given the novelty of the topic, there neither much literature nor consensus on what the features of a sustainable, fair, and zero waste business model is or could be. Building on the best practices in the European market we have identified four criteria as key to identify what a virtuous business model would look like:

The good news is that there are several European textiles companies working along the lines of at least one or two of the criteria above – thus, a blueprint is probably somewhere out there. However, more research is needed in this field to better define what a virtuous business model looks like, as well as more action from a legislative and non-legislative perspective.