ACIMIT– Association of ltalian Textile Machinery Manufacturers, represents an industrial sector that comprises roughly 300 manufacturers (employing around 13,000 people), which produce machinery for an overall worth of around 2.7 billion euro, of which 86% are exported in about 130 Countries, mainly in Asia and Europe. Creativity, sustainable technology, reliability and quality are the halmarks that have made Italian textile machinery worldwide leaders and the technological level of its production is considered of the highest standard by the competitors themselves.

Italian textile machinery manufacturers meet the full spectrum of industry needs (spinning, weaving, knitting, dyeing, finishing, printing and laundry machines). A lot of them produce machines for technical and innovative textiles too, maximizing the flexibility and versatility that characterize Italian supply.

Italian textile machinery industry: figures

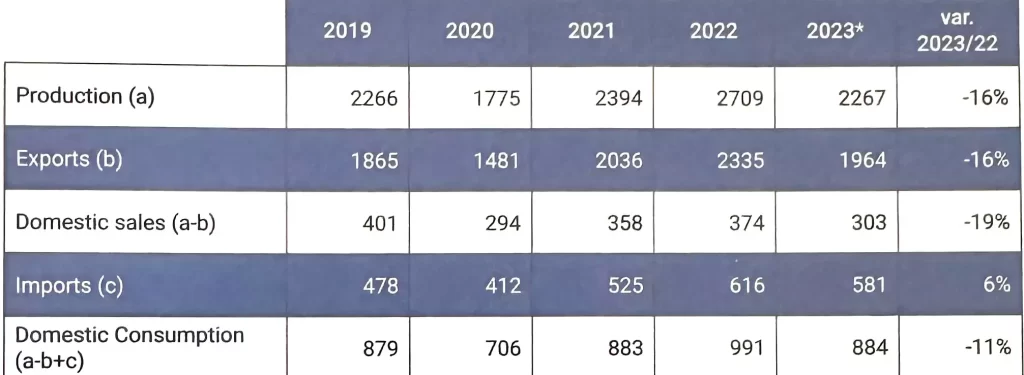

In Italy there are approximately 300 companies who produce textile machines and related accessories, for a total of about 12,900 employees. In 2022 the value of Italian production was 2.7 billion euro, while in 2023 the production value is expected to be about 2.3 billion euro.

In Italy there are approximately 300 companies who produce textile machines and related accessories, for a total of about 12,900 employees. In 2022 the value of Italian production was 2.7 billion euro, while in 2023 the production value is expected to be about 2.3 billion euro.

Italian textile machinery exports

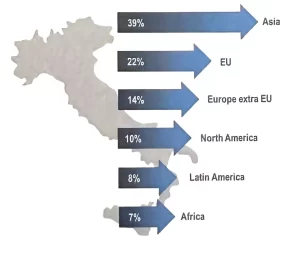

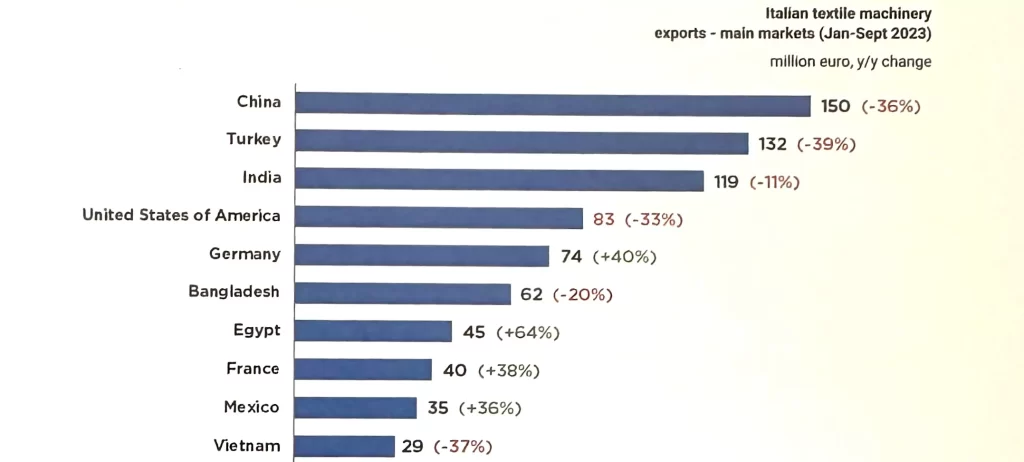

86% of Italian total sales are realized in about 130 destination Countries. The process of internationalization and the vocation for innovation in the sector, allowed Italian companies to consolidate and further improve the leading posítion of ltaly in the world textile machinery industry. In the first nine months of 2023 the main destination of Italian exports of textile machines was Asia (39%), followed by European Union (22%) and Europe extra EU (14%). The biggest contribution to the Italian exports of textile machinery came from China. Italian sales toward Chínese market amounted to a value of Euro 150 million. Others main markets are Turkey, India and United States of America.

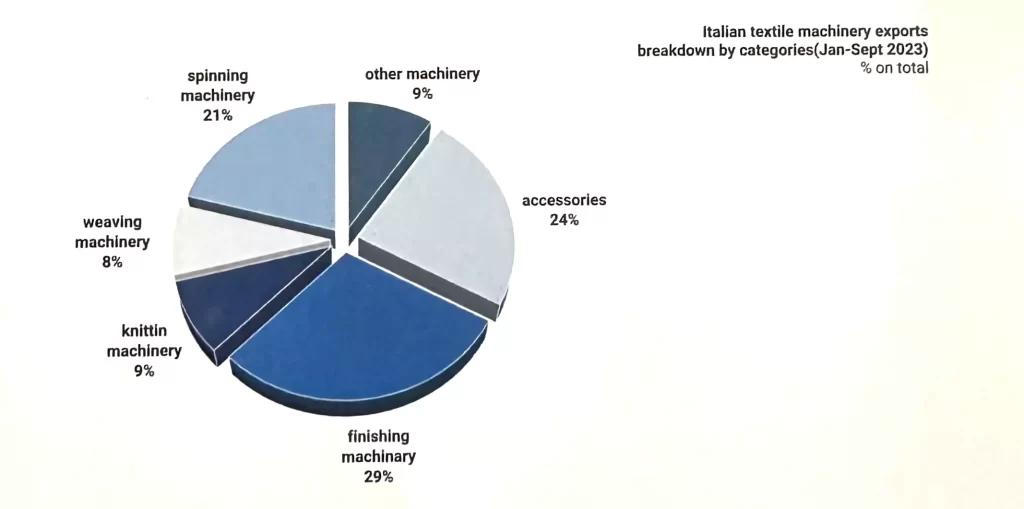

In the first nine months of 2023 the main destination of Italian exports of textile machines was Asia (39%), followed by European Union (22%) and Europe extra EU (14%). The biggest contribution to the Italian exports of textile machinery came from China. Italian sales toward Chínese market amounted to a value of Euro 150 million. Others main markets are Turkey, India and United States of America. The supply of Italian manufacturers covers all the classic sectors into which we can divide textile machines. Each type of machines are well represented in the Italian exports.

The supply of Italian manufacturers covers all the classic sectors into which we can divide textile machines. Each type of machines are well represented in the Italian exports. Reasons for a world success

Reasons for a world success

Italian companies involved in this sector, are small-size companies, deeply Committed to R&D activities, looking for close cooperation with end users to create new opportunities, new machines, new systems and technologies.

The ability to understand the needs of potential customers enables Italian companies to turn them quickly into dedicated machines and devices which give rise to new high value-added market niches (such as the technical textiles) in the world textile market, both as regards economical and technological aspects.

Italian textile machinery companies are placed in areas of ancient textile tradition, where an exchange of experience with end users offers a strong impetus to the

constant technological upgrading of machinery. Textile clusters are located in Northern and Central Italy: Bergamo, Biella, Brescia, Como, Milan, Prato, Vicenza.

The main characteristics that distinguish Italian textile machinery sector are:

- Skilled workforce that ensures a high quality of products;

- The dimensions of Italian companies that allow a quick response to the need of each customer;

- The flexibility and versatility ensure a customized production for satisfyíng the needs of each customer;

- The high technological level of the supply, due to the constant attention paid by Italian companies to the R&D activities and to innovative solutions.

Green technologies for a sustainable textile production

Innovation is nowadays more and more strictly connected with sustainability in different fields: environmental, social and above all economic one. Textiles and clothing are a fundamental part of everyday life and an important sector in the global economy. Nevertheless the clothing production system has several negative environmental and social impacts. In front of these data an environmental awareness among final consumers has growing, capable to leading a change in the textile value chain.

Combining respect for the environment and productive efficiency through lesser use of the resources involved in the textile production process is a common goal for many companies in the textile industry. In this new trend where sustainability of the products and the attention to the environment are the key topics, Italian textile machinery manufacturers are in the forefront. Italian companies are already successfully offering solutions able to reduce the consumption of water, energy and raw materials, at the same time increasing energy efficiency and reducing costs. In other terms supporting their customers to be more competitive in the World scenario.

In their constant commitment to a more sustainable textile supply chain, ACIMIT and its member companies have developed the “Sustainable Technologies” project. At the center of this initiative there is the Green Label, that aims to identify the energy and environmental performances of each machines and make them easily recognizable and comprehensible. Through a survey on the green labels produced from 2016 to date, the quantified avoided emissions are 1.2 bilion tons. of Carbon Dioxide equivalent, corresponding to 221,187 cars traveling for 35,000 km over a year (on average).

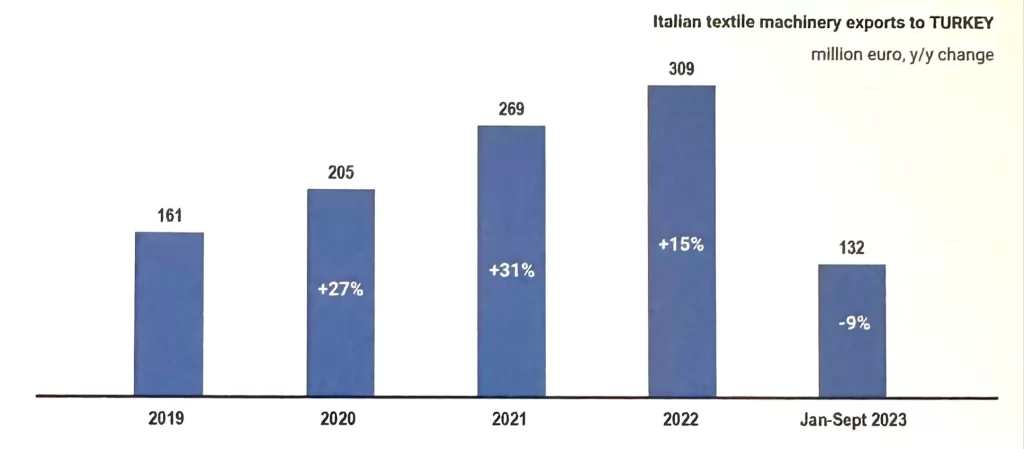

Turkey, an excellent partner for Italian manufacturers of textile machinery

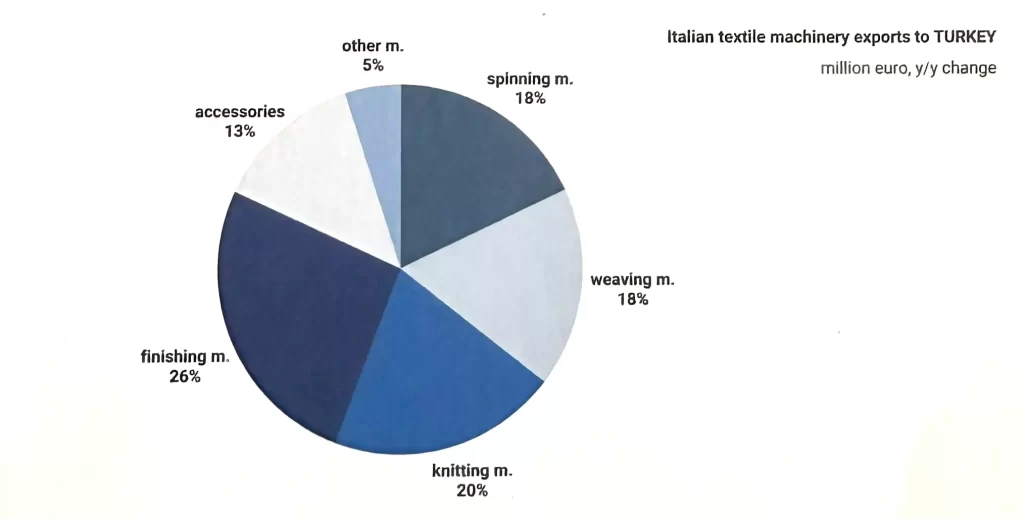

The important role that Turkey plays in the international textile and clothing industry has made the Country one of the world’s leading markets for textile machinery. In particular Turkey is the second foreign market for the Italian textle machinery manufacturers. In 2022 Italian exports to the Turkish market reached a value of 309 million euro, while in the first nine months of 2023 Italian sales amounted to 132 million euro. The most relevant share of the ltalian machines exported to Turkish market was for the finishing machines (26%), followed by knitting machines (20%) and weaving and spinning ones (18%).

The most relevant share of the ltalian machines exported to Turkish market was for the finishing machines (26%), followed by knitting machines (20%) and weaving and spinning ones (18%).