Unique, world-first, new features in GSDCost will enable brands to easily source, secure and compare multiple Cost-to-Make submissions from suppliers to facilitate more accurate and meaningful purchasing decisions

Coats Digital is delighted to announce that it has developed world-first new functionality in its award-winning, scientifically-based GSDCost solution to enable brands to collaborate more effectively and meaningfully with vendor partners and support more sustainable and responsible growth across the fashion supply chain.

The new functionality in GSDCost will enable brands to harness the power of scientifically-backed international standard time benchmarks based on accurate Standard Minute Values (SMVs) to create credible Bill of Labour (BOL) garment style requests, issue these to multiple vendors at the same time, and compare and contrast the various Cost-to-Make (CM) responses quickly from one platform.

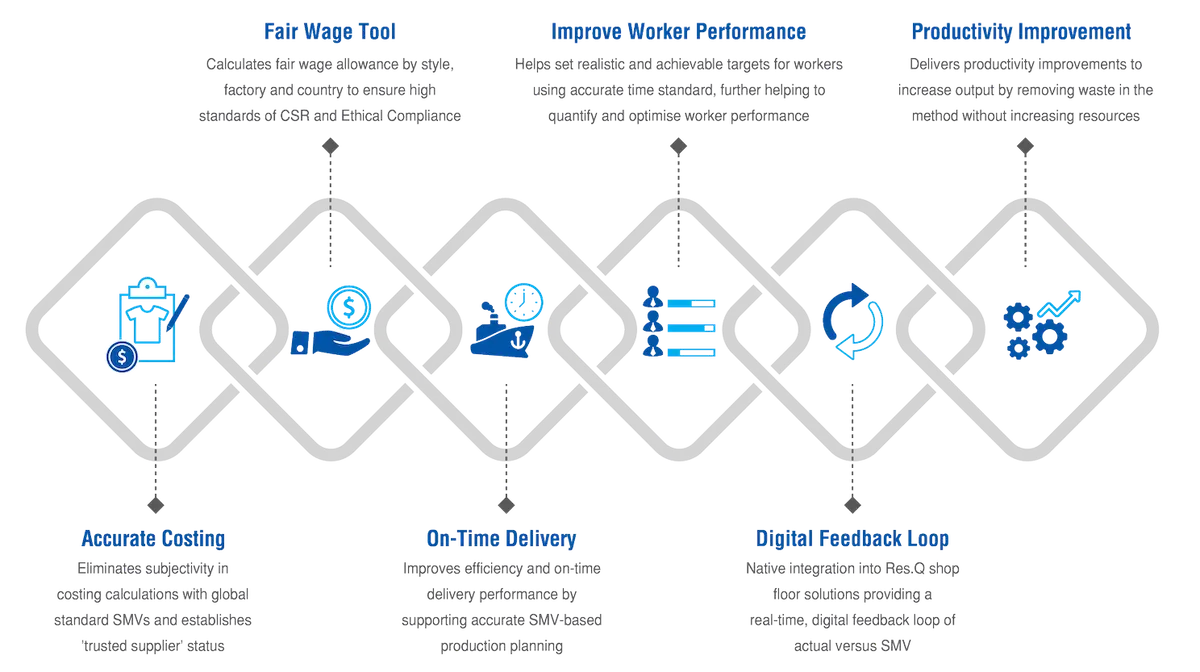

Coats Digital’s GSDCost method analysis and pre-determined times solution is widely acknowledged as the de-facto international standard across the garment industry. The solution supports a more collaborative, transparent and sustainable supply chain, in which brands and manufacturers establish and optimise ‘International Standard Time Benchmarks’. This use of a scientific, common language and standards supports accurate cost prediction, fact-based negotiation, and a more efficient garment manufacturing process, while concurrently delivering on CSR commitments.

GSDCost’s enhanced feature of a globalised Fair Wage Tool – with data provided by the Fair Wage Network also enables brands and manufacturers to quickly agree the fair living wage allowance for any given garment, in any factory in the world.

Stuart McCready-Stocks, Brands Commercial Director, Coats Digital, said: “We have listened carefully to what our brand customers have been saying about the challenges they face trying to collaborate more effectively and meaningfully with suppliers whilst securing more accurate CM quotes based on a standardised set of criteria. We have consequently worked hard to develop a set of unique, brand-focussed features in GSDCost, which will enable brands to Create, Collaborate and Compare credible BOL estimates using the same language and means of assessment for all vendors across their value supply chains. Brands have never before been able to create multiple sourcing routes so quickly or compare vendors with the same degree of impartiality and clarity based on the same scientifically-anchored criteria and we expect this powerful tool will be a real gamechanger for brands in the years to come.”

The new Create, Collaborate and Compare elements in GSDCost will ultimately give brands the robust data insights they need to create a master overview of the productivity outputs, machinery capabilities ethical compliance and fair wage practices of each of their vendor partners. Using a set of specific departmental SMV metrics including Cutting, Machining, Inspection, Pressing and Packing, brands will consequently be able to drill down into specific BOL discrepancies between vendors, factoring in whether one vendor has perhaps more advanced machinery or increased automation, for example, or another has more expensive, but better sustainability and fairer wage practices. This will also significantly help brands quickly ascertain which vendors fall short of new global compliance rules and which suppliers they would like to work more closely with.

“Off the back of climate disasters, economic uncertainties, geopolitical unrest and high inflation, brands and fashion retailers continue to face significant challenges with a slew of new regulatory EU and US regulations set to mandate stringent, compliance measures around sustainability and fair wages that will ultimately make them much more accountable for the working practices of their vendor partners, adds Stuart McCready-Stocks. “This new, powerful tool within GSDCost, backed by the Fair Wage Network and the International Labour Organisation (ILO), therefore, could not have come at a better time, since we can now help brands foster a much more transparent and collaborative relationship with all their supply partners – not only ensuring best working practices in general, but also meeting new industry compliance challenges – together.”

Customer Testimonials:

Nitin Kumar, Technical Lead, C&A Sourcing Asia: “Through standardised time, method, cost and time management methodology, GSDCost will bring robust transparency to C&A’s sourcing process so it can collaborate effectively with partners to support more sustainable growth.”

Sampath De Silva, Administrator, ODLO Romania S.R.L: “Coats Digital’s GSDCost is the only solution that provides scientifically-assessed code generation analyses for various production tasks, and it was the obvious choice to ensure we could achieve rigorous, consistent data insights that would ultimately make a significant impact to our efficiency and profitability. GSDCost has enabled us to efficiently establish accurate SMVs based on method engineering, and as a result, we have reduced our SMVs on core styles by 13% and improved overall productivity by a whopping 10%.”

Yasemin Gür Solmaz, Board Member, Gürmen Group: “Our company, which exports to 25 countries around the world, is always open to collaborations with solutions compatible with the goal of producing quality and valuable products based on innovation. We believe Coats Digital’s GSDCost solution will add value to our efficient resource and performance management strategy for a fast, competitive, uninterrupted, efficient and data-driven lean manufacturing business model.”