In a recent interview with Mr. Paul Rushton, Commercial Director of Technical Absorbents (TAL), we delved into the remarkable journey of TAL within the global market for superabsorbent fibers, fabrics, and yarns.

Over the past three decades, how has Technical Absorbents (TAL) expanded and flourished within the global market for superabsorbent fibers, fabrics, and yarns?

Technical Absorbents (TAL) was established as a collaboration between Courtaulds and Allied Colloids – the former being a manufacturer of super absorbents and the latter being an expert in spinning – the net result was the successful development, manufacture and launch of a fibre that was inherently superabsorbent.

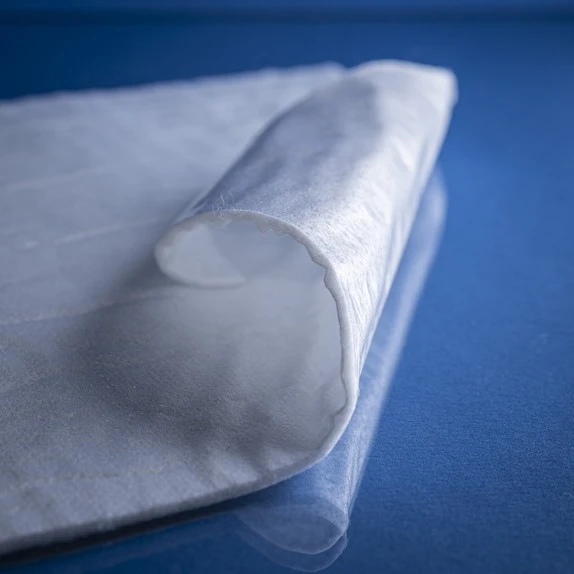

Growing global demand for our Super Absorbent Fibre (SAF™) technology has led to various capacity expansions over the past 30-years. We have also become heavily engaged in the design and manufacture of SAF™-containing nonwoven fabrics – airlaid, needlefelt, carded thermo-bonded – and spun yarns. These are either manufactured in-house on our state-of-the-art nonwoven line or via our network of global converters.

What distinctive qualities or innovations distinguish Technical Absorbents’s superabsorbent materials from others in the market?

SAF™ is like Super Absorbent Powder (SAP) but in staple fibre form and is inherently super absorbent. It is this – plus the fact it can be blended easily with other synthetic and natural fibres – that makes our fibres so special. SAF™ is at the core of each of our products and it provides rapid levels of absorption – up to 200 times its own weight in water – and excellent retention.

How does Technical Absorbents effectively manage distribution and provide client support on a global scale given its widespread presence?

Today we have a loyal and expanding global customer base – over 99% of our products are exported – that operate within a wide range of industries.

SAF™ technology can be found in products, including absorbent food packaging; advanced wound dressings; filter media; structural waterproofing membranes; and power and fibre optical cables.

How has Technical Absorbents (TAL) adapted its products over the years to meet the evolving needs and advancements in various industries?

We continue to develop new absorbent technologies (absorbent fibres, fabrics, and yarns). Our team works closely with customers during every step of the development process, from initial enquiry/brief to product delivery to ensure our absorbent materials perform as required.

How does Technical Absorbents (TAL) stay at the forefront of innovation in materials technology, ensuring that its products remain technologically advanced?

Research and Development has been fundamental to our growth. We continue to innovate and bring unique SAF™ fibre, fabric, and yarn technologies to market that provide customers with the exact superabsorbent solutions they require. We often run full-scale development programmes over many months to engineer a specific bespoke solution.

How do you evaluate the superabsorbent materials in the MEA and Turkey market?

We regularly receive enquiries from companies MEA and Turkey. We have an agent in the latter who supports is with our activity in the region. Wherever a customer is located, we can support technically and commercially from our facility in the UK.

Sustainability is a growing concern. How does Technical Absorbents (TAL) address sustainability in the production and distribution of its superabsorbent materials?

Commitment to improving sustainability performance is a core value of TAL. We engage with all stakeholders to balance the needs of the environment, society, and shareholders.

Reviewing and improving our processes and operations is ongoing to ensure that all activities and business decisions are undertaken and agreed with sustainability in mind.

Looking ahead, what are Technical Absorbents’s plans and aspirations for the future, and are there specific areas of product development or market expansion that the company is focusing on?

One of our latest innovations is a highly engineered washable superabsorbent fabric for use within reusable hygiene pants and pads. This is a growing market due to a consumer desire to move away from less sustainable disposable alternatives.

We are now working with numerous companies who are striving to create products to enhance performance and wearer comfort. We continue to work with many development customers in a wide range of other application areas.