Interview with Mr. Yigit Durak / Durak Tekstil

By: Behnam Ghasemi / Kohan Textile Journal

Let us know more about Durak Tekstil’s history and success story.

Mr. Ali Durak founded the Durak Tekstil textile company for the first time in 1972. This company’s initial focus was printing and weaving fabrics, but after a few years of operation, the founder became aware of a void in the Turkish Textile market. And this severe shortage of fishing net threads prompted the company to invest in producing this kind of thread, which served as a crucial foundation for our current level of success.

The second generation of the Durak family inherited the company in the 1980s. My father, Mr. Ömer Durak, finished his chemical engineering studies at BASF, Germany, as well as different specialized dyeing courses. The company’s operations have remained in this direction ever since he returned from Germany when he once more altered the company’s focus to the specialist manufacturing of embroidery and sewing threads.

ÖMER DURAK introduced technology previously reliant on foreign countries and was not available in Turkey, allowing Durak Textile to manufacture polyester embroidery threads in Turkey for the first time in 1985, eliminating the need for the country to buy such products.

The Durak company took a huge step forward with its production. After that, we started making rayon embroidery threads before making more specialized sewing threads.

60% of Durak Tekstil’s products are currently exported to over 80 countries. Manufacturing shoes, automobiles, security, and medical uniforms are just a few businesses that employ Durak sewing threads. Additionally utilized in the apparel sector and for furniture decoration are embroidery threads.

Our primary export destinations are European countries, and we deliver our products to the market according to the most rigorous and high-quality European requirements.

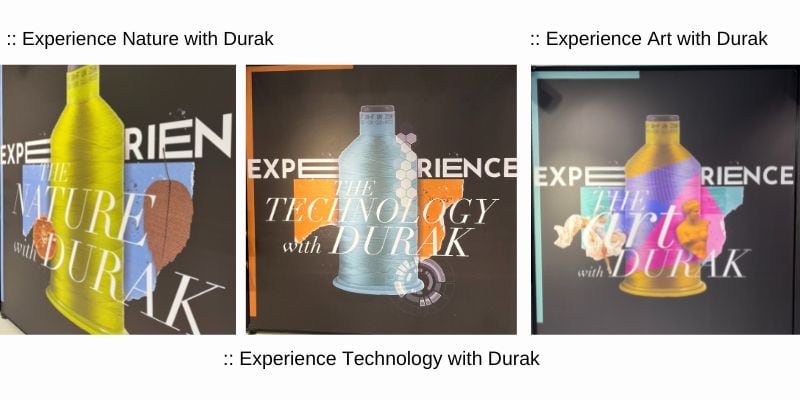

As the Durak company celebrates its 50th anniversary this year and after 50 years of producing sewing and embroidery threads with a focus on quality, we want to transcend manufacturing and industry by renewing our vision. Due to this, we began by outlining our narrative, which is divided into three key sections: experience nature with us, experience technology with us, and experience art with us.

Dorak has advanced over the past fifty years through hard work and innovative thinking. Now is the time to share technology and art more with our devoted customers while showcasing our abilities and capacities by fusing our products with nature. Let’s usher in a new age. Developing a connection between Durak products and art is crucial to this change.

The technological textile industry is another one in which Turkey leads the world. The model we presented at the Istanbul textile expo shows a portion of the city of Bursa. However, even though it wasn’t our intention to bring Bursa, the highly conductive Durak threads served as a conduit for the electricity that powered the train, the lighting, and other devices.

We are engaged in the production of non-cuttable threads in addition to conductive threads. These yarns create protective gloves, clothing, and pants for heavy metal industries that are resistant to tearing and being struck by pointed items.

Additionally, our most recent product was created by Durak Tekstil and offered on the market for the first time. The usefulness and efficiency of the human body, muscles, and movement are improved by this new thread. This product promotes athletes and the elderly to live better with more balanced lifestyles.

This product will be unique in the entire world. With the finalization of the brand registration and ownership of this product, we anticipate being able to display it by the end of the year.

We change the game, and this balance-improving product will be used primarily in the medical and health industry for older people. I lost my grandfather to a hip break, a typical issue for older people.

This product cannot prevent all issues, but even if it can reduce 5% of accidents and help elderly pearls, it is a big success for our team. And this is how a company turns into a well-known global brand. We try to add value to our products and brand.

Tell us more about your point of view on sustainable and green products. What is Durak tekstil sustainability policy?

Sustainability has been a part of our culture in Durak Textiles; we have had a recycling pool for our dying house since 2006. We always think about nature, and we are conscious of our environment.

Recently we have received our GOTS and GRS certificates. We are a certified supplier of recycled and organic textiles in that manner. We can provide our polyester product portfolio in recycled versions, including continuous filament embroidery, sewing threads, and textured threads.

We can also supply organic cotton and lyocell products to our portfolio; now, we have only staple Lyocell, which is as strong as cotton. In the future, we will launch our new lines for continuous filament Lyocell, which will probably take the place of many other products because it is more sustainable.

As you know, rayon fibers are produced only from two types of trees that only grow in Canada and Siberia but currently, China pre-bought all of the trees, showing us it is a limited resource. Still, Lyocel is produced from trees which grow everywhere, faster and cheaper.

We have more than 40 engineers in our R&D daily working on new developments and projects. We think our path and future are worthwhile investments and challenging efforts.

What do you think about Turkey’s overall yarn manufacturing industry?

We have lots of companies in the yarn sector in Turkey, especially for sewing and embroidery threads, and every day some new company is born. Some of them focus only on the domestic market, and some brands have a bigger vision for international exports.

In Turkey, one of the biggest textile manufacturers in the world, the yarn manufacturing sector is developed, and it has a bright future with many new investments and technologies.

In recent years Turkish textile yarn manufacturers have understood to pay more attention, money, and time to R&D and innovation.