Interview with Rafael Matos – KTK Portugal

By: Kohan Textile Journal

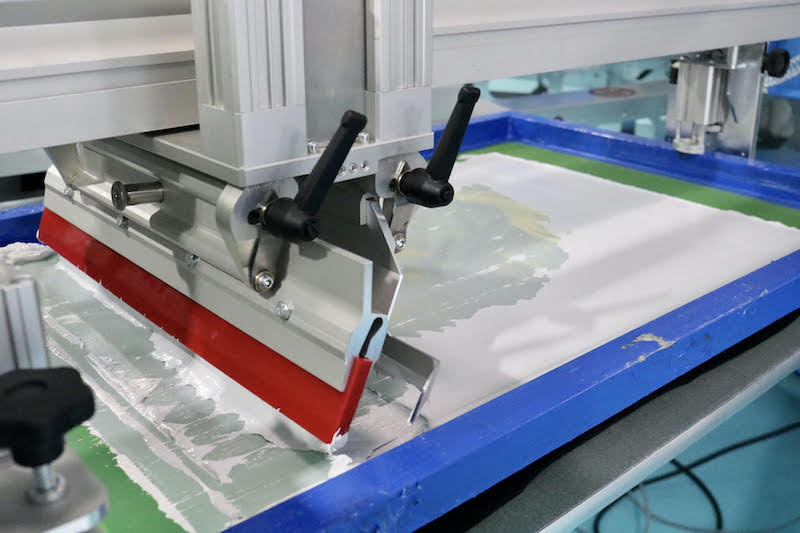

About KTK Portugal, history and success story: KTK was founded in May 2014, with the main goal of bringing to the market what for us was the best, easiest and safest tools for the day-to-day work of the modern screen-printing technician.

At the moment KTK is present in most textile manufacturing markets, constantly reaching new territories as we speak. During our existence, we had to increase our facilities 3 times, and by the end of the summer, KTK will have increased 10.000 m2 more when compared to last year.

We pride ourselves on giving opportunities not only to established talents of the industry but also to young talented people who are eager to learn and show what they are made of. This diversity inside our team brings new ideas and perspectives, which help us to make KTK the fastest rising screen-printing machinery manufacturer in the World.

2 -Let us know about service and types of machinery that you offer to the textile and fashion sector?

KTK builds top of line screen-printing machinery, to answer the most demanding needs of modern screen-printing technicians around the World. Currently, we are also developing digital printing hybrid solutions, with our innovative KTK Fusion line, which has been very reliable and successful.

3 -Could you please explain more about KTK latest innovations in screen-printing machines?

Besides introducing patented technology that increases the lifetime of all screen-printing machines KTK produces, KTK is also successfully developing its digital hybrid printing line to offer an even larger array of solutions to screen-printing technicians.

4 -How do you evaluate the Textile industry in Portugal?

terms of the textile industry in Portugal, we are lucky to have some of the best companies in the industry located here. We can easily test our machinery at local clients’ facilities, which we know are following the highest quality standards, and understand where we should be focusing our attention and developments.

5 -In recent years digital printing has developed fast, how do you evaluate screen-printing machines future in competing with digital printers?

We believe there will always be a market for screen-printing machines. The level of productivity of screen-printing machines and the low-cost consumption/maintenance of them, when compared to digital printing units, is truly remarkable. We believe the future is to combine these two technologies, in order to enjoy the best features of both.

6 – The Middle East and Africa is an important destination for screen-printing machines, how do you evaluate the textile and fashion industry in this region. Do you have any customer or export to this region?

We export a lot to African markets and Turkey. In fact, Turkey is one of our best markets and is fastly rising. The quality they offer on their prints can already be compared with the best. Our digital printing modules are already present in Turkey too, which means it is a market that is striving to be in the front run of development. We have also seen an increase in demand from central African countries that are fastly developing their textile markets.

7 – How we can improve sustainability in the textile industry?

Sustainability should always be a concern in this industry. Taking a closer look at the chemicals used to produce inks and the garments themselves could lead us to a better future.