The Streat Drycom 8 Series Moisture Measurement & Control systems allows Streat customers to optimise their production processes by ensuring product moisture is at the desired level.

This is the legacy of over 30 years of experience and continuous progress in Moisture Measurement and Control. A focus on development led by the client’s requirements combined with Streat’s instrumentation expertise has led to the premier range of Drycom Moisture Measurement and Control Solutions that will be on display at ITMA 2019 in Barcelona.

Streat Instruments’ moisture systems are designed to assist users in optimising production conditions in order to maximise productivity, quality, operating efficiencies and profitability in the nonwoven and traditional textiles industries.

In both nonwoven and traditional textiles, processors are aware of the importance of moisture management during processing. It is well known that the moisture content of fibres affects how they perform during the various stages of processing. Finding and maintaining the optimum moisture content provides clear benefits in both processing performance and product quality.

“One effect of over-dry material is the creation of static and for most fibres it can also reduce fibre strength and make the fibre brittle, resulting in excess fibre breakage, increased drop out and reduced yields. On the other hand, a product that is too wet can block fibre transports, cause roller laps and can lead to the build-up of bacteria,” says Jim Herbison, Sales Manager of Streat Instruments.

Drycom 8 Lite

The latest addition to the Drycom suite of products will be on display at ITMA 2019.

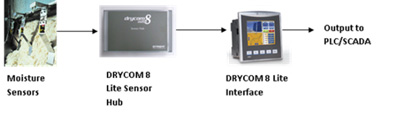

The Drycom 8 Lite has been developed in response to market demand for a lower cost solution that will integrate into existing Plant Control systems. “If a customer already has a Plant Control (e.g. PLC/SCADA) system in place it does not make sense to have a separate Operator Interface for Moisture Measurement and Control, so for these situations, the Drycom 8 Lite seamlessly integrates into the exisiting Plant Control system,” says Herbison.

The Drycom 8 Lite system can store up to 5 Calibrations, has a single 4 to 20mA output of Moisture Content and uses a small Touch-Screen for the Operator interface (including a display of Moisture).

A variant of the Drycom 8 Lite has been developed that can provide up to three 4 to 20mA outputs of Moisture Content (one for each Moisture Sensor). This is of interest to processors who want to measure the moisture of a narrow or homogenous flow of product in different locations (e.g. multiple heat setting lines, gilling or combing machines or cotton gins).

The Drycom 8 Lite system will be of interest to customers of older generation Streat Moisture Meters requiring upgrading that are connected to Scourcom Plant Management systems or in plants where Plant Management systems have been added.

Streat Moisture Solutions for Sustainable Processing

Drying is one of the most energy-intensive operations in textile processing. Streat Drycom empowers processors to reduce energy usage by optimising the drying process.

Drycom measures the fibre directly and ensures consistent moisture by continuously measuring the moisture of the fibre, yarn, nonwoven web, or other product at the exit of the dryer. This moisture information is used by either the Drycom Controller or the existing Plant Control system to automatically control the energy and/or speed of the dryer to maintain the desired level of moisture.

Alternatively, in processing areas where plant humidity control is not enough to ensure optimum moisture conditions (e.g. opening and blending prior to carding) a Spray Control system can be incorporated to raise the product moisture to the desired level of moisture. This avoids the need to maintain high humidity levels in the plant thus preventing an uncomfortable environment for workers and avoiding high energy costs and potential machinery damage.

“In addition to ensuring consistent moisture content, the productivity gains and energy savings provided by our systems are considerable,” says Herbison.

Hundreds of Streat Drycom systems are already providing users in over 40 countries with the tools they need to operate sustainably, optimise production processes and maximise productivity, quality, operating efficiencies and profitability.

we need a upgraded model of moisture control system our 15 year old streat moisture meters are not worked now. please send a proposal for bleaching unit cotton dryer machines.