Among basic necessities of life, clothing is the first. Human’s pursuit for fancy clothes has never stopped. With the rapid development of the economy and technology and the improvement of aesthetic taste and quality of life, clothing has not only met the basic needs of covering the body and keeping warm but also the pursuit of personality, comfort and fashion.

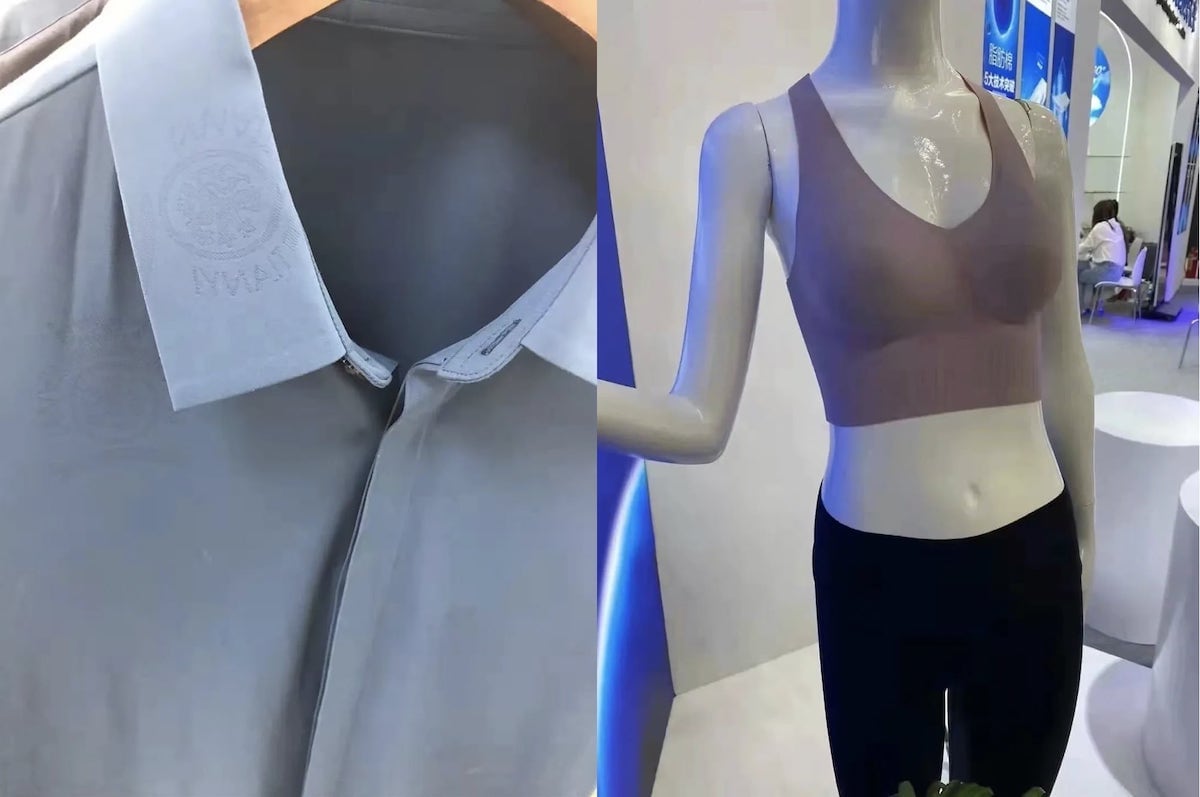

In light of this, seamless knitting technology came into being, with its three-dimensional structure, integral shaping, fit and comfort, soft appearance and health care functions and other characteristics, favoured by consumers.

Seamless knitting technology, as an advanced form, greatly enhances the comfort and aesthetics of knitted garments through the use of special seamless knitting equipment and digital simulation, which allows for one-off molding of garments. This technology is not only used in underwear and sportswear, but also in outerwear, casual wear, fashion, and healthcare apparel, making it a highlight in the textile and garment manufacturing industry.

Global and Chinese Seamless Knitwear Market

According to the latest research report, the global and Chinese seamless underwear market size reached 288.935 billion yuan and 75.614 billion yuan respectively in 2023, and the global seamless underwear market size is expected to grow at a CAGR of 11.08% to 545.863 billion yuan by 2029. This data fully demonstrates the market potential and growth momentum of seamless knitting technology.

In the global market, the total sales and exports of seamless knitwear continue to climb. China, as an important production base for seamless apparel, not only has a huge domestic demand market, but also a significantly higher export capacity. Numerous Chinese seamless garment manufacturers have successfully entered the international market and won the favor of global consumers by virtue of their advanced production technology and high-quality products.

At present, China’s seamless garment manufacturing industry has formed a number of industrial clusters, mainly in Yiwu, Zhejiang Province; Chaoshan, Guangdong Province; and Shandong. These clusters have played an important role in promoting the development and competitiveness of the industry.

In the future, as the global seamless garment manufacturing market continues to expand and consumer demand diversifies, competition among clusters will become more intense. However, this also brings more development opportunities and challenges for the seamless garment manufacturing industry.

01 Yiwu, Zhejiang Province: Yiwu has become one of the most important production bases for the seamless garment manufacturing industry in China with its well-developed trade network and strong manufacturing capacity. The region has more than 600 seamless garment manufacturers and auxiliary industrial chains, with a wide range of products of excellent quality, which are exported both at home and abroad. Among them, the output of seamless underwear occupies 30% of the global market share and 80% of the national.

02 Shandong: The seamless garment manufacturing industry in Shandong, represented by Qingdao and other places, has strong technical research and development capabilities and production strength. Enterprises in the region focus on product quality and branding, and actively explore domestic and international markets, and have made remarkable achievements.

03 Chaoshan, Guangdong Province: With its unique location and abundant labor resources, it has become an important development area for the seamless garment manufacturing industry. Enterprises in the region are focusing on technological innovation and branding, and are constantly improving the added value of their products and market competitiveness.

Seamless Clothing

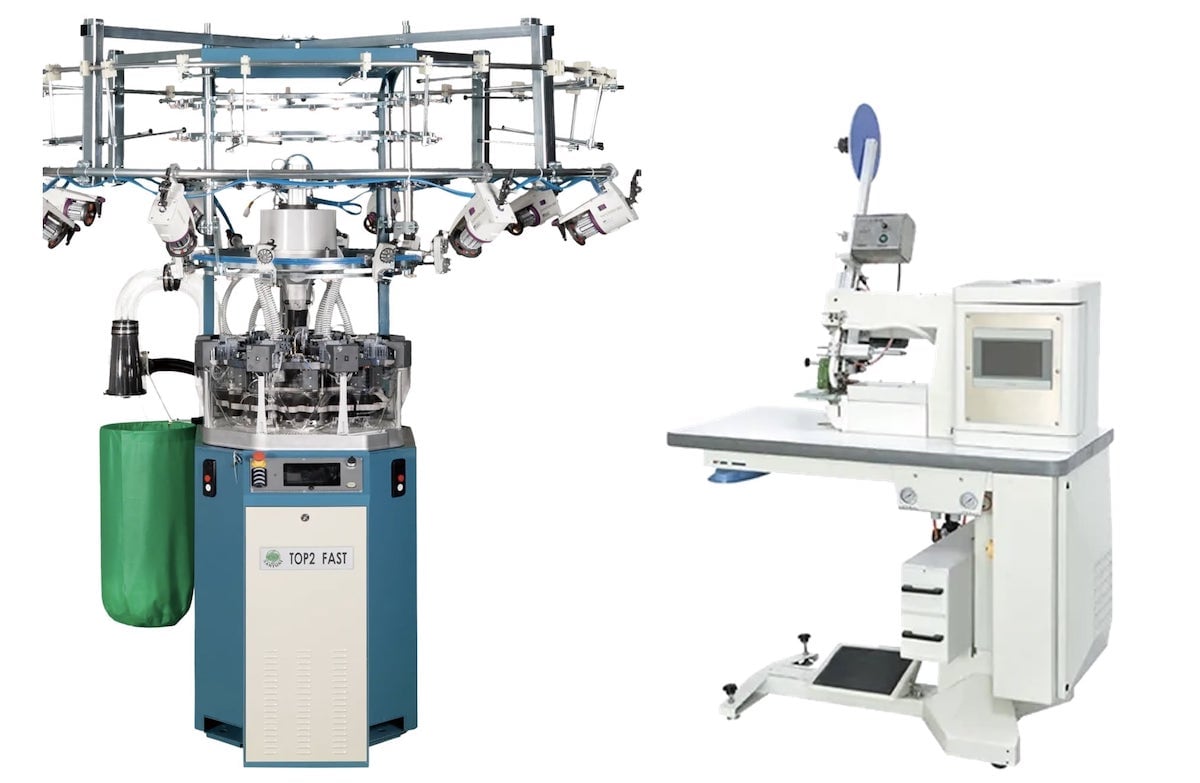

The rapid development of seamless knitting technology has directly led to the export and application of related equipment. Various types of seamless knitting machines, underwear machines, intelligent garment production and logistics equipment, etc., have become the popular products for the global textile and garment manufacturing industry to purchase. This equipment not only improves the production efficiency, but also reduces the production cost, which promotes the rapid development of the seamless garment manufacturing industry.

In the seamless garment manufacturing industry, the production capacity of mainstream enterprises has also become an important indicator of their competitiveness. With the continuous progress of technology and the increasingly fierce market competition, more and more enterprises are focusing on equipment upgrading and technological innovation. Some large-scale enterprises have introduced advanced seamless garment production equipment and technology to achieve efficient and accurate production, setting a role model for the industry.

2025 ITCPE (Guangzhou International Seamless Clothing Industry Technology Exhibition)

As a platform for exhibition, communication and cooperation, ITCPE 2025 is born out of this trend, which bridges domestic and international seamless garment manufacturing industry in technical exchange and cooperation, but also serves as an important window to promote industrial upgrading and stimulate innovation and vitality.

The exhibition brings together the world’s best seamless garment production equipment manufacturers, raw material suppliers, design software developers and cutting-edge technology researchers to showcase the latest production equipment, efficient processes, intelligent management systems and environmentally sustainable material solutions.

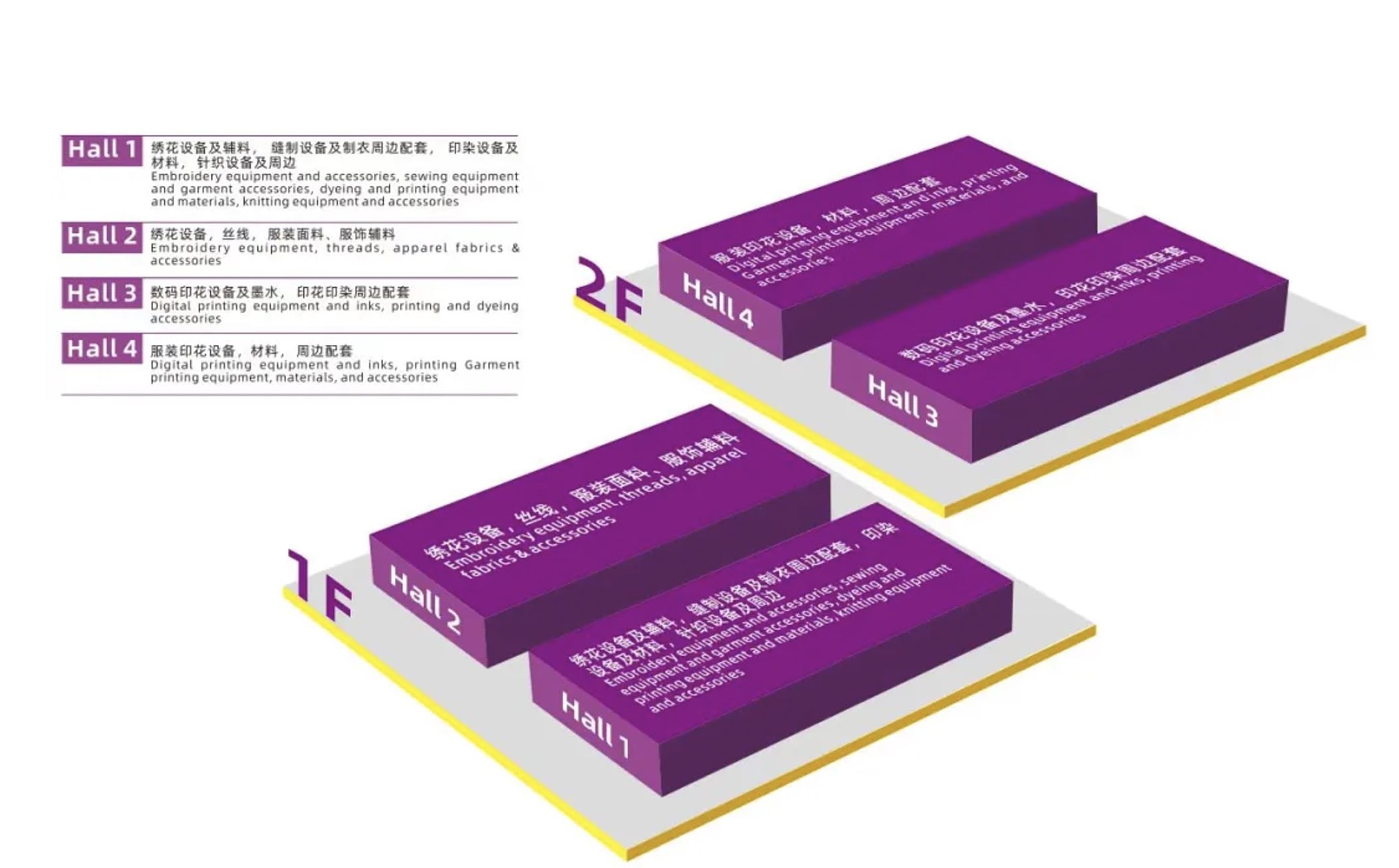

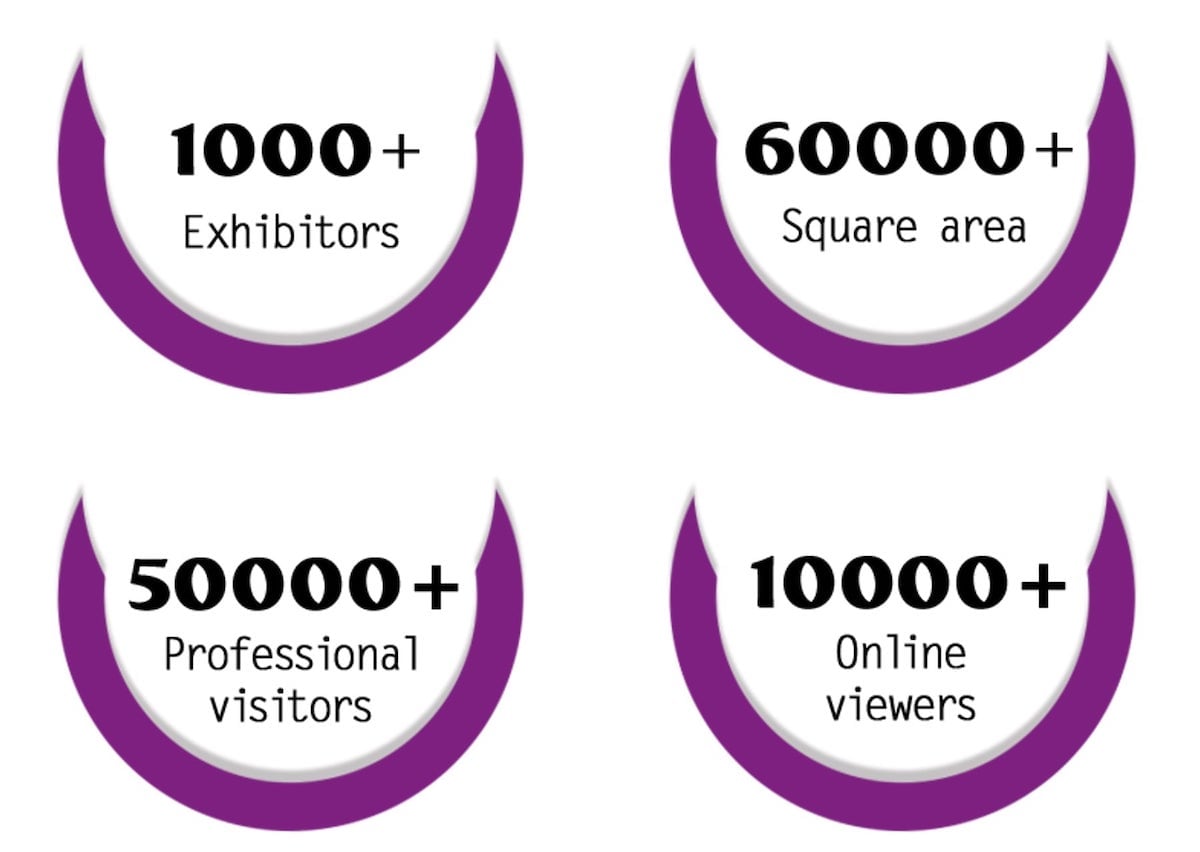

The show is one of the four thematic exhibitions of the Guangzhou Textile, Clothing & Printing Industry Expo, which will be held on May 19-21, 2025 at Poly World Trade Center, Pazhou, Guangzhou, with a total exhibition scale of more than 60,000 square meters, bringing together nearly 1,000 exhibitors and attracting over 6,000 professional visitors to the venue, presenting a visual and technological feast for everyone.

# Exhibition Scope

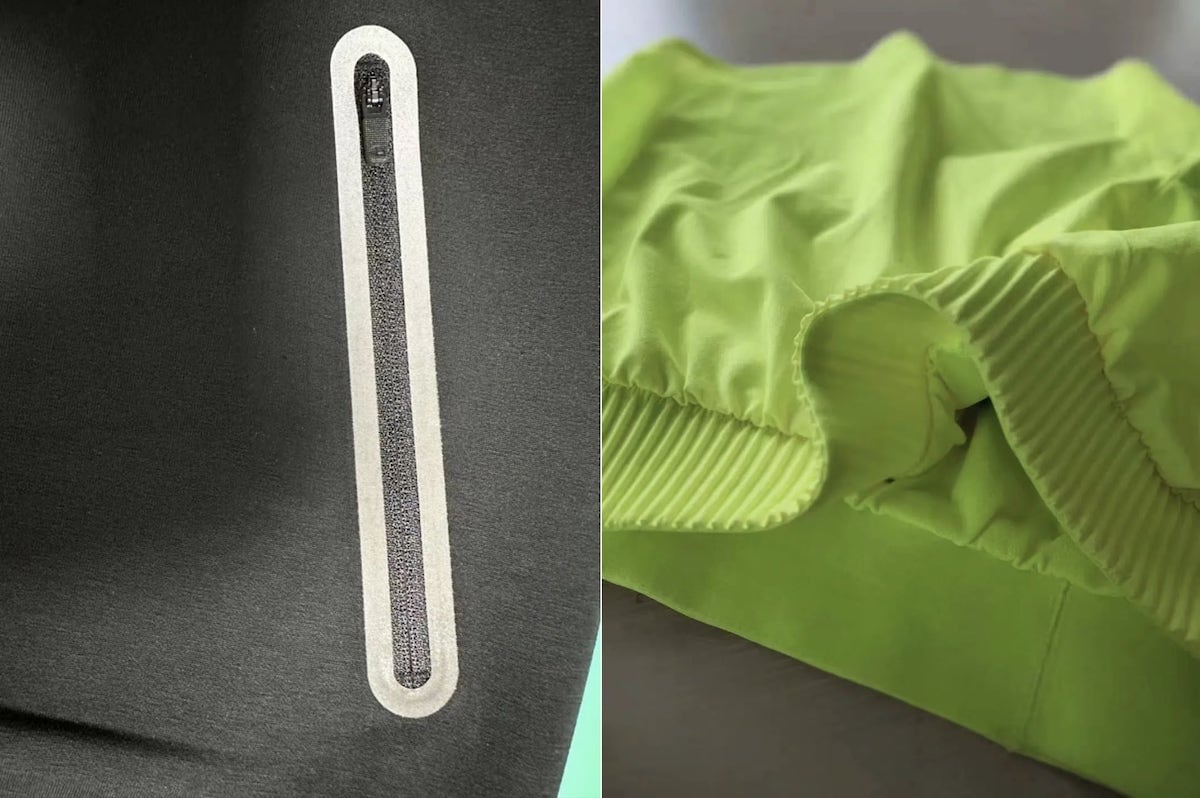

The scope of the exhibition covers seamless calendaring equipment, weaving equipment, ultrasonic/laser equipment, automated post-sewing equipment, garment customization equipment, all kinds of embroidery equipment and accessories, consumables and yarn, fabrics and accessories, etc., which comprehensively demonstrates the vast applications and infinite possibilities of seamless knitting technology.

Seamless calendaring equipment:

Full-set clothes seamless fusing machine, edge cutting & gluing machine, cloth strip fusing machine, edge wrapping & fusing machine, men’s trousers seamless processing machine, sportswear seamless fusing & splicing machine, flatbed pressing & ironing machine, mark ironing machine, seamless spot-welding heat-pressing machine, hot air blower, ultrasonic seamless underwear machine.

Weaving equipment:

All kinds of seamless knitting machines, underwear machines, knitting and sock knitting machines, circular knitting machines and flat knitting machines, ribbon knitting machines, jacquard embossing machines, trade mark weaving machines, yarn covering machines, yarn twisting machines, intelligent garment production and logistics equipment, intelligent sewing equipment, intelligent embroidery equipment, intelligent hanging systems, pre-shrinking & bonding equipment, etc.

Ultrasonic/Laser Equipment:

High-performance laser cutting machine, engraving machine, cutting machine, laser marking machine, ultrasonic heat-melting & sewing machine, ultrasonic lace machine, ultrasonic patching machine, ultrasonic cutting equipment;

Automated post-sewing equipment:

High-performance full-set clothes ironing & shaping equipment, automatic sewing & sealing equipment, lockstitch button sewing equipment, uniform washing equipment, intelligent testing, needle detection equipment, intelligent storage, transport & packing equipment, core-spun yarn equipment, dyeing equipment, lace machine, overlock machine, knotting machine, sewing machine, other management software.

Apparel customization equipment:

3D body scanning & imaging equipment, intelligent 3D fitting system, customized garment printing equipment, garment customization-based systems, software and other technology and equipment related to Internet plus Garment Industry 4.0.

All kinds of embroidery equipment and accessories:

Single-head and multi-head computerized embroidery machines, bead embroidery computerized embroidery machines, shuttle embroidery machines, computerized gold embroidery machines, hand-cranking embroidery machines, plate-making centers, strike-off sewing machines, etc.; needle bar drivers for computerized embroidery machine, high-speed embroidery machine parts, high-speed machine drivers, three-in-one drivers, single-head machine drivers and various types of drivers, sliders, etc.

Consumables and yarns:

Core yarn, hot melt adhesive film, hot melt adhesive strips, all kinds of rayon threads, floral threads, polyester embroidery threads, gold and silver threads, gold and silver threads, night threads, polyester-viscose yarns, cotton yarns, polyamide filaments, acrylic threads, chemical fibers, yarns, etc.

Fabrics and accessories:

Swimwear and underwear fabrics, loungewear fabrics, all kinds of functional fabrics, accessories and fittings, zips, logos, buttons, heat press, diamond beads, patches and sequins, branded apparel manufacturers, sportswear manufacturers, underwear factories, swimwear factories, designers and so on.

The 2025 Guangzhou International Seamless Garment Manufacturing Industry Technology Exhibition is not only an event to display the latest technology achievements and industry trend, but also a key step to promote the transformation and upgrading of the seamless garment manufacturing industry and achieve high-quality development.

It will lead the global seamless garment manufacturing industry to a brighter future with an open attitude and forward-looking perspective, and contribute to its prosperity. We are looking forward to meeting you at the Poly World Trade Center, Pazhou, Guangzhou, from May 19-21. Let’s work together to promote prosperity. Let’s share this feast of technology and art!