Why COLARIS Digital Inkjet Printing System should be the choice for your future investment

ZIMMER AUSTRIA digital printing journey started in 1976 when the first CHROMOTRONIC high-capacity inkjet printer was supplied to a carpet manufacturer in Kidderminster, UK.

Through constant research and development over more than 45 years ZIMMER AUSTRIA Digital Printing Systems has gained and proven exceptional know-how supporting its customer base as well as new projects.

A COLARIS carpet printer is complemented with various print line components for ink fixation, washing and drying. ZIMMER AUSTRIA will be your partner to define, build and deliver your optimized production environment.

The heart of the COLARIS printer is based on the robust and scratch proof FUJIFILM Dimatix Starfire™ GS-1024 printhead with ReadiJet™ and VersaDrop™ technology. The Starfire™ printhead is the only truly repairable printhead on the market today. ZIMMER AUSTRIA offers through its Printhead Reconditioning Center an extended service life which additionally helps to reduce the total cost of ownership for the print line.

A permanent ink circulation system with multi-step filtration and degassing system ensures optimum print condition for precise printing results.

The open ink system allows a customer to select from various inks and suppliers

Certified inks from the best manufacturers with the widest range of chemistry can be used. Owed to this specific feature, COLARIS printers are capable to print on almost any fiber available in the market. Fibers such as Polyamide (Nylon®), Polyester, cationic Polyester, PAN (Acrylic Fiber), Sorona®, as well as cotton, viscose, linen, jute, coir…, or wool and silk are just some of the prominent fibers that are printed with COLARIS digital inkjet printers.

Different fibers need separate ink classes. Mostly the printers are set up for one ink class only. In few exemptions, two individual ink classes may be combined within a single print line. Nevertheless, this is only feasible in case of an identical fixation process.

Cost-efficient production through an extended life cycle

Low operational costs and stable production are guaranteed through the robustness and precision of the printer. Accurate positioning and uncompromised fixation of the carpet substrate on the transport belt is a basic need. Permanent control of conveyor transport in combination with a position-controlled linear drive motor for the print carriage ensure maximum precision in printing.

Electronic components including firepulse-, data- and head interface boards are developed by ZIMMER AUSTRIA, just like the COLARIS Print Engine which stands for operators’ comfort and excellent print results. It offers several optional features that can be licensed as per a specific product or customer’s need. A comprehensive diagnostic system is part of the print engine and supports our worldwide operating service team, to minimize downtime in the event of a malfunction. Tele-maintenance guarantees software support throughout the service life of a COLARIS printer.

Through constant research and development in our Digital Technology Center the COLARIS high-resolution printing system can compete with CHROMOJET technology, proven for many years. The COLARIS technology requires less space, less energy, reduces water consumption drastically and does not need a color kitchen, saving investment, space and labour costs substantially.

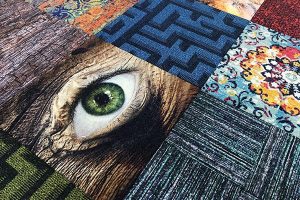

Versatility for optimized product configuration

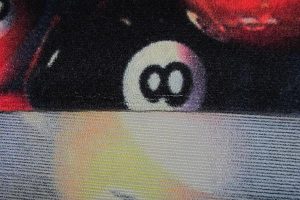

The wide range of carpet products covered through COLARIS Digital Inkjet Printers includes individual door mats, carpet tiles, rugs, woven, tufted, or needle-punched carpet substrates, no matter whether they are intended for contract, semi-contract, or residential use. Other applications may include promotional and event carpets or even automotive end-use.

Let us know about your demand and we will jointly find the right solution for your specific need.