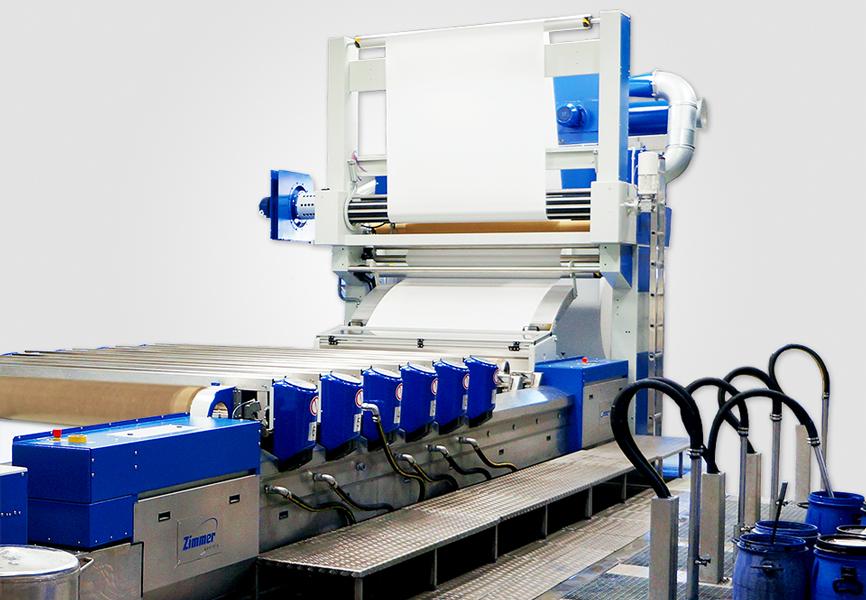

Zimmer Austria’s ROTASCREEN.TG is a revolutionary rotary screen printing system that sets new benchmarks in textile production through exceptional precision, enhanced efficiency, and extensive versatility. Developed from Zimmer Austria’s profound engineering expertise and extensive market insights, the ROTASCREEN.TG technology dramatically advances the capabilities of textile manufacturers worldwide.

ROTASCREEN.TG addresses the specific needs of diverse textile market segments, including fashion, home textiles, technical textiles, and specialized military fabrics. Its innovative design optimizes both large-scale production runs and smaller, customized batches. This versatility ensures consistent quality regardless of the fabric type, supporting materials from delicate natural fibers to robust, high-performance synthetics.

As textile production increasingly emphasizes sustainability, ROTASCREEN.TG incorporates advanced monitoring technology that significantly reduces water, energy, and chemical consumption. This supports manufacturers’ efforts in adhering to strict environmental standards, providing an eco-friendly yet highly productive printing solution.

Core Technology and Innovations

At the heart of ROTASCREEN.TG lies Zimmer Austria’s innovative ZIMMER MAGNET SYSTEM PLUS. This cutting-edge system seamlessly integrates advanced magnetic rod technology with conventional blade application methods. By ensuring uniform distribution of print paste, ROTASCREEN.TG substantially reduces inconsistencies common in traditional screen printing. The magnetic rod system achieves unmatched print clarity and allows for precise, intricate detailing, even on complex substrates such as fine nylons and textured polyesters.

Further, ROTASCREEN.TG is engineered to provide outstanding accuracy at high speeds, operating effectively at up to 120 meters per minute. This impressive capability is made possible through precision-engineered closed-bearing systems that deliver unmatched stability and reliability during continuous production cycles.

The modularity of ROTASCREEN.TG supports different color application systems, including the versatile Variocolor ASG, the efficient Air-Flow blade squeegee, and the precision-engineered BVS microchannel system. Manufacturers can thus select application methods specifically tailored to their unique production requirements, further enhancing print quality and process efficiency.

Advanced Digital Synchronization

ROTASCREEN.TG incorporates advanced digital synchronization technology, significantly reducing setup times and downtime. By digitally synchronizing screens, printing units, and the substrate feeding mechanism, ROTASCREEN.TG maximizes operational productivity and flexibility. This sophisticated technology also supports automatic repeat settings, ensuring accuracy and consistency throughout each production cycle and facilitating swift transitions between print jobs.

Digital synchronization ensures minimized fabric waste and optimized material usage, directly enhancing production sustainability and cost-effectiveness. The integration of smart sensors and automation technologies within ROTASCREEN.TG further supports precise control over the entire printing process, delivering uniform results and maintaining high quality across extended production runs.

ACR-5 Control Software

Integral to ROTASCREEN.TG is Zimmer Austria’s advanced ACR-5 control software, featuring a user-friendly, intuitive touchscreen interface. This sophisticated control system stores extensive data on job-specific parameters, enabling quick recall and efficient management of repeat print runs. Operators benefit from streamlined workflows, reduced error potential, and enhanced repeatability, significantly boosting overall productivity.

The ACR-5 system provides detailed analytics and insights into operational performance, enabling real-time adjustments and optimizations. This enhances resource management and significantly improves process reliability, critical for complex designs and high-demand applications such as military and technical textiles.

ROTASCREEN.TG Technical Specifications

| Feature | Specification |

|---|---|

| Maximum Printing Speed | 120 meters per minute |

| Magnetic Rod Technology | Zimmer Magnet System Plus – uniform paste distribution |

| Screen Synchronization | Digital synchronization with printing blanket for precise repeats |

| Energy Monitoring System | Real-time tracking of water, gas, and electricity consumption |

| Control System | ACR-5 touchscreen-based, stores multiple job parameters |

| Substrate Compatibility | All natural and synthetic fibers, including technical textiles |

| Color Application Options | Variocolor ASG, Air-Flow blade squeegee, BVS microchannel system |

| Sustainability | Reduced consumption of water, energy, and chemicals |

| Repeatability | High precision, accurate repeat patterns |

| Application Precision | Fine detail printing capability, uniform quality across fabric width |

Zimmer Austria continuously invests in research and development, refining ROTASCREEN.TG technology to stay ahead of global textile industry trends and demands. By consistently updating and improving the system’s capabilities, Zimmer Austria empowers textile manufacturers to achieve unparalleled standards of production quality, sustainability, and efficiency, ensuring long-term market leadership and competitive advantage.