Vietnam’s textile and garment industry, one of the country’s key export sectors, is undergoing a crucial transformation fueled by eco-innovation. As global demand rises for environmentally responsible production, Vietnam is aligning its growth strategies with sustainability goals, aiming to enhance competitiveness, reduce environmental impacts, and secure a stronger position in the global value chain by 2030.

Eco-Innovation: A Dual-Purpose Transformation

Eco-innovation involves introducing new or improved products, technologies, and business models that reduce environmental impacts while creating economic value. Unlike traditional innovation that focuses on profit, eco-innovation emphasizes resource efficiency, circular economy practices, and sustainable development. For the textile industry, this translates to changes in production processes (energy and water savings, chemical reduction), product innovation (use of recycled or natural fibers), and sustainable supply chain management.

According to the OECD, eco-innovation supports both environmental stewardship and economic progress. In Vietnam’s textile industry, clean technology investments often achieve a return on investment within 1–3 years—proving they are both viable and beneficial.

A Sector Facing Global Pressures

Textile and garment production globally is a significant contributor to carbon emissions, water consumption, and wastewater discharge. With new environmental regulations taking effect in major export markets—like the EU’s Sustainable Textiles Strategy and Carbon Border Adjustment Mechanism, or the U.S. Clean Water Act—Vietnam must adopt greener practices to maintain and grow its market access.

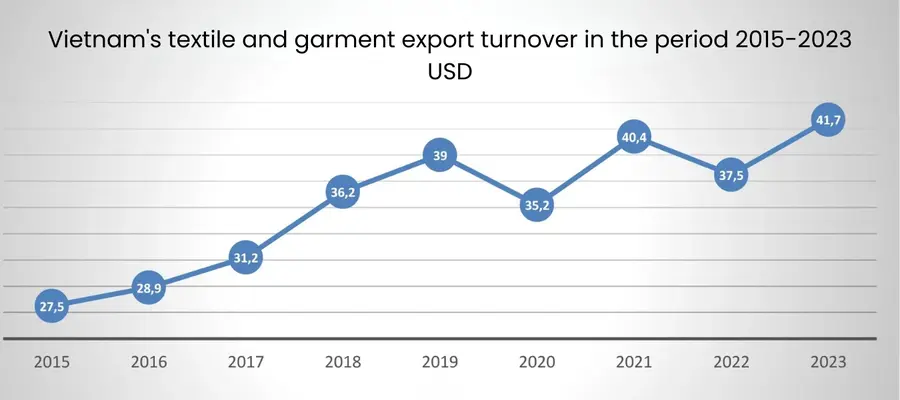

Vietnam’s Party and government have identified innovation and green growth as national priorities. The textile sector, which generates $44 billion in exports annually and employs around 2.5 million workers, is central to this strategy. But challenges persist, from high wastewater levels to inefficient energy use in production.

Progress on the Ground

Many Vietnamese textile companies have embraced eco-innovation. According to a 2023 VITAS survey, 65% of enterprises have implemented at least one eco-innovation measure, up significantly from 2018. Leading companies are investing in energy-saving and water-recycling technologies. For example:

- Hoa Tho Textile JSC built a closed-loop water treatment plant, reusing 40% of wastewater and saving $350,000 annually.

- May 10 Corporation introduced an “Eco-Wear” product line made from recycled PET bottles and organic cotton, increasing export value by 15–20%.

- Phong Phu Corp adopted Cold-Pad Batch dyeing, reducing water usage by 60%.

Business model innovations are also gaining momentum. Firms like Vinatex and Viet Tien are recovering textile waste for reuse, while Nha Be Garment has launched a “Green Factory” certified to LEED standards, reducing energy consumption by 35% and boosting premium orders by 25%.

These efforts have already shown tangible results: eco-innovating firms report revenue growth rates 15–20% higher than the industry average and greater labor productivity. Green-certified textile products fetch a 10–15% premium in international markets.

Barriers and Challenges

Despite these gains, the road to a sustainable textile industry is not without obstacles:

- Financial Constraints: Green technologies require significant upfront investment, often ranging from $1–3 million per factory. Small and medium enterprises (SMEs) struggle to access the necessary capital.

- Skilled Workforce Shortage: 60% of firms lack personnel trained in green production and compliance with global standards such as OEKO-TEX or GOTS.

- Weak Legal Framework: Inconsistent policies and overlapping responsibilities between ministries create regulatory confusion.

- Low R&D Investment: R&D spending in the sector is just 0.5–0.8% of revenue, far below international standards.

Vision for 2030

With the right policies and support systems in place, Vietnam’s textile industry can become a global leader in sustainable production. If 80% of firms adopt eco-innovation by 2030, the sector could reduce carbon emissions by 30%, contribute an additional 0.5% to annual GDP, and create 200,000 green jobs.

To reach this potential, a comprehensive national strategy is essential. The following key actions are recommended:

Strategic Recommendations

Incentivize Green Investment: Introduce tax exemptions and interest subsidies for eco-innovation projects. Rapid depreciation on green equipment and higher tax incentives (30–40%) can attract more SMEs.

Establish National Sustainability Standards: Develop the Vietnam Sustainable Textile Index (VSTI) to benchmark and promote sustainable performance across firms.

Invest in R&D and Technology Transfer: Create a National Center for Sustainable Textile Technology with a focus on energy efficiency, recycling, and eco-design. Allocate 5% of national science funding to green textile R&D.

Develop a Skilled Green Workforce: Launch dual-training programs for “Green Textile Engineers” combining classroom education with hands-on industry training. By 2030, the industry will need at least 8,000 engineers and 20,000 skilled green workers.

Strengthen Global Partnerships: Engage with international partners like the EU, Japan, and South Korea for technology transfer, joint projects, and green investment inflows.

Conclusion

Eco-innovation is not a trend but a necessity. For Vietnam’s textile and garment industry, it offers a path to environmental responsibility, economic resilience, and global competitiveness. With concerted efforts by the government, businesses, and international partners, the sector can lead Vietnam’s green transformation—turning sustainability from a challenge into a strategic advantage.