“Next June 2022, ITM in Istanbul will be the first major textile equipments expo since the pandemic outburst. This is a major opportunity to meet in person with many of our long time Turkish partners” says Christian Guinet, the Secretary General of the French Textile Equipments Manufacturers’ association.

He knows this market particularly well as he travelled around Turkey for many many years when he was the marketing manager of a world leader equipment manufacturer.

The global turmoil due to the coronavirus has slowed many personal visits but, thanks to new communication techniques, innovation has continued to take place both in end products, equipments and production processes.

Christian Guinet adds “market changes are what our industry is about, it is quicker and quicker whatever the day-to-day issues. Then, our members have to be closer and closer partners for their customers in order to interact with them, understand their needs, focus their R&D to find solutions, offer state-of-the-art equipments and the best service to every customer.

French textile equipment manufacturers are R & D and service geeks. As they are SME’s run by entrepreneurs just as their Turkish customers, it is very easy for them to understand each other very well and to go beyond usual business relationships”.

France is the sixth textile equipment exporter worldwide. The French Textile Equipment Manufacturers are well known for their catalogue and tailor-made equipments. They also offer turnkey solutions including one or several companies in a one shop model.

They are particularly strong in long fibre spinning (wool, acrylic …), yarn twisting and control (including technical yarns), space-dyeing, heat setting for carpet yarns, carpet systems, bleaching and hydro-extractor equipments, dyeing and finishing, felts and belts for finishing processes, precision machining and textile ERP.

For many years, the French have been very active on the Turkish market. In Gaziantep, they were the first ones to organize a national pavilion, it was back in 1995. In Izmir and Gaziantep, they have organized road shows. Of course, they have been active on each ITM. They are eager to meet their customers next June 14-18.

NSC fibre to yarn /Hall 3 Booth 315E

“NSC fibre to yarn” continues to develop Tow to Top lines with the model S200 of stretch breaker followed by the new model of Defelter rebreaker D5GC40 and the GC40 chain gill. As finisher m/c, the FMV41/42 vertical rubbing frame takes place.

Recently, “NSC fibre to yarn” has installed semi-worsted lines with SW35 carding m/c card (2.5 m or 3.5 m wide), manufactured by N. Schlumberger followed by preparation lines consisting of chain gills model GC 40 and finishers m/c model FMV41/42.

“NSC fibre to yarn” offers to modernize recycling lines for acrylic fibres or blended fibres by introducing its well-known combing machine ERA between card and gills drafting. The contribution of the combing machine ERA is economically essential according to 4 points of view:

– production: 1 ton per day in 3 deniers. (3 shifts). – cleanliness: 25% of neps less compared with PB family m/c. – energy consummation: equipment with economic saving: Use of energy efficient motors. – reduced consumption of spare parts owing to a new design of kinematics.

“NSC fibre to yarn” remains continuously at the disposal of its Turkish customers. To offer the best service, an organization of spare parts has been set up with the BILGE/Automation company and Samoteks, the agent for Turkey, is well known by all customers.

“NSC fibre to yarn” will be on the booth of his agent SAMOTEKS.

SUPERBA/Hall 2 Booth 215A

Superba, member of the VANDEWIELE family of companies, will present their latest developments for the carpet industry.

Active on the Turkish market since the early nineteen’s, Superba is the leader in heat-setting and space-dyeing for carpet yarn, with a total of more than 350 lines sold in Turkey.

Being close to their customers has always been the force of Superba, with the strong support of their agent SAMOTEKS-Makina in Istanbul and a large inventory of spare-parts managed by their exclusive distributor, BILGE-Otomasyon located in Gaziantep, at the customers’ doorstep.

.

Yarn used in carpet is becoming thinner and thinner, new types of fibers are used, new extrusion methods are applied to create new types of yarn. This permanent evolution requires adapted processes, more efficient and connected machines to allow the development of products with new, customized properties.

To meet all these demands, Superba is offering a wide range of machines and processes, and has introduced new textile processes.

Already the leader in heat-setting with saturated steam under pressure thanks to their well-known TVP3, Superba is now offering their hot-air heat-setting solution with the DHS3 line.

This triple-layer heat-setting process provides an unequaled level of evenness and a highly homogenous fixation characteristic to the yarn, as well as stain resistance or enhanced bulk. The DHS3 line offers a high energy saving process in a reduced floor-space.

To complete their range, Superba is also introducing their new B403 automatic winder. expanding its area of application beyond the carpet yarn field, the B403 marks a real technological breakthrough with its individual spindle motorization drive; it enables a constant tension winding process, an accurate bobbin length measuring as well as a unique quality control for each yarn position.

The winder can be connected through cloud computing to the VANDEWIELE “Texconnect” supervision system to comply with the Factory 4.0 concept.

Finally, with the BXE extrusion line from VANDEWIELE, the MF400 texturizing machine and the MCD3 space-dyeing machine as complementary processes before heat-setting, with Superba lines, the carpet industry gets all the necessary equipment to produce innovative yarn types, allowing manufacturers to make the highest quality carpets at the most economic prices.

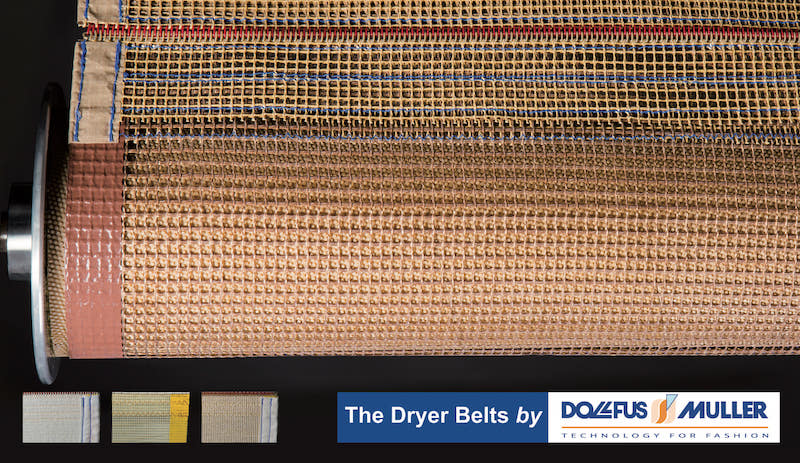

DOLLFUS & MULLER Hall 12 Booth 1219B

Dollfus & Muller is now more than 200 years old. They manufacture specialized technical textiles: endless felts and endless belts.

Dynajet is a sales department of Dollfus & Muller specialized in fabrics for ink jet printers and wide widths fabrics for theaters and events.

The endless felts and dryer belts are designed for the textile finishing and nonwovens factories:

– compacting felts for knit finishing

– sanforizing felts for denim and woven fabrics finishing

– printing dryer belts for textile printing

– sublimation blankets for transfer printing

– decatizing felts for wool finishing

– dryer belts for thermo-bonding ovens

– tensionless dryer belts for knit finishing

Dollfus & Muller improves the compacting felt for knit finishing with major evolutions in order to serve better the dyeing houses. The compacting felt quality brings a special care to the fabrics thanks to its smoothest surface, has an excellent guiding and the best compacting rate in relations with its new exclusive compacting felt design.

The Dollfus & Muller sanforizing palmer felts are ideal for Denim producers. The Dollfus & Muller Sanfor felts are recognised by most of the major machine makers as the best felts.

Furthermore, Dollfus & Muller manufacture durable printing dryer belt qualities. These print dryer belts are the most durable printing dryer belt specially designed for pigment printing of bed sheeting.

Dollfus & Muller has its exclusive print open mesh belt specially designed for the production of fine fabrics, scarves, flags, these belts have special non marking surfaces which can avoid as well the particles on the back side. Dollfus & Muller has the widest range of printing dryer belts and the strongest dryer belts.

Finally, Dollfus & Muller improved the transfer printing felt. This felt is resistant against the heat and dye staff insuring a perfect transfer of colorants on the fabrics.

Since 2013, M. Ali Ҫetin is the agent for compacting felts in Turkey. Since then, the customers have recognized Dollfus & Muller’s felts were giving better shrinkage control and life. Price uniformity and fairness were also introduced