Textile Full Dyeing Process is the process of applying dyes or pigments to textile materials such as fibers, yarns, and fabrics in order to get the desired color and colorfastness.

In dyeing, temperature and time management are two crucial elements. The textile dyeing process is recognized as one of the most environmentally unfriendly industrial processes. Thus, finding alternative, eco-friendly methods for dyeing textiles is fundamental.

One of the most important aspects of effective textile commerce is the dying procedure. Aside from the design and attractive color, the consumer usually looks for basic product qualities, such as washing resistance, during and after lengthy usage. To achieve such qualities, the compounds that color the fiber must have a high affinity, a consistent hue, be resistant to fading, and be cost-effective.

Textile Colorants

Dyes and pigments are two types of colorants with different properties that lead to substantial changes in how they are applied to textiles. Dye is a colored substance that is fixed to fabric and is generally employed in solution. Dyes are categorized based on their use and chemical structure, and each type of fiber requires a special dye.

The dye must be ‘fast’ or chemically stable, meaning it will not wash off with soap and water, fade in the sun, and so forth. Dyes are water-soluble and attract to fabrics by both primary (ionic or covalent bonds) and secondary (hydrogen bonding) forces while dyeing or printing on textiles. On the other hand, pigments are insoluble and have no affinity for textile fibers.

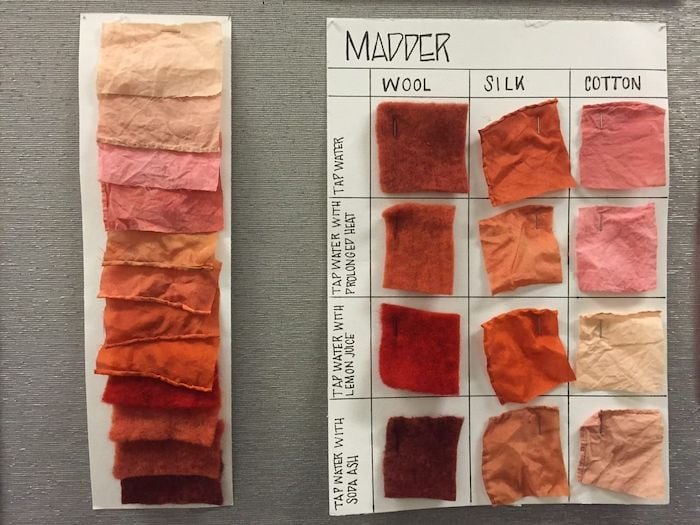

Natural dyes are dye compounds derived from natural sources. Despite being the primary source of colors in the past, synthetic dyes have mostly supplanted them as they are more reliable, less expensive, and more readily available. Haematoxylin, carmine, and orcein are examples of natural dyes that are still used.

Synthetic dyes are dyes made from organic or inorganic compounds. Direct, Acid, Basic, Reactive dye, Mordant, Metal complex, Vat, Sulfur, Disperse dye, and other dyes fall within this category.

Textile Full Dyeing Process

The dyeing methods have not changed much throughout time, and dyeing is usually done in a specific solution that contains dyes and other chemicals. Water is mainly used to clean, dye, apply auxiliary chemicals, and rinse textiles. Preparation, dying, and finishing are the three processes in the dyeing process. Before dying, undesirable contaminants are removed from the materials during preparation.

Cleaning can be done with aqueous alkaline chemicals and detergents, or enzymes might be used. Many fabrics are bleached with hydrogen peroxide or chlorine-containing compounds to remove their natural color. In case the textile is going to be sold white, optical brightening agents are added.

Dyeing is the aqueous application of color to textile products frequently at high temperatures and pressures. Surfactants, acids, alkali/bases, electrolytes, carriers, leveling agents, promoting agents, chelating agents, emulsifying oils, softening agents, and other chemical aids are applied to the textile during this step to achieve a uniform depth of color with colorfastness properties suitable for the fabric’s end-use.

Different fastness qualities may be required depending on the intended end-use of the materials. For example, automobile textiles must not fade after extensive sun exposure. Many types of dye and chemical additives are utilized throughout the finishing process to achieve such features. Pigments and binders which fix the pigment to the fibers can also be used to dye fabrics.

Finishing entails applying chemical compounds to the material in order to improve its quality. Fabric treatments used in the finishing process include waterproofing, softening, antistatic protection, stain removal, etc.

Dyeing Methods

Textiles can be dyed through a batch or continuous process. The type of material (fiber, yarn, fabric, clothing), generic type of fiber, dye batch size, and dyed fabric quality requirements are among the factors that determine the best dyeing procedure.

Batch dyeing involves loading a textile substrate into a dyeing machine and bringing it to equilibrium, or near equilibrium, with a dye solution, where dye molecules leave the dye solution and enter the fibers since they have an affinity for fibers.

Auxiliary chemicals and carefully managed dyebath conditions (most notably temperature) help to speed up and enhance the dyeing process. Heat and chemicals are used to fix the dye in the fiber, and the stained textile substrate is washed to remove unfixed colors and chemicals.

Beam, beck, jet, and jig processing are examples of batch or exhaust dyeing techniques. Moreover, pad dyeing can be done in a batch or a continuous process.

In the continuous method, the dye is transferred to the substrate continuously by passing it through various steps. Heat and steam are delivered to long rolls of fabric as they travel through a series of concentrated chemical solutions in continuous processing. The continuous method is an innovative process that combines several distinct dyeing stages, such as color application, fixation, and washing out unfixed dyes.

Dyeing Machinery

Coloration can be done at any stage throughout the production of textile products. Dyeing machines are available for dyeing textiles in the form of loose stock, tow, slubbing, sliver, yarn, or fabric. Fabric can be colored in all its forms, including woven, nonwoven, and knitted fabrics, as well as hosiery and clothing. As a result, there are many different dyeing machines available.

Dyeing textile materials at various phases of production has both advantages and downsides. Dyeing textiles early in the manufacturing sequence, such as loose stock, has the advantage of randomizing any non-uniformity that may emerge with dyes with poor migration qualities during subsequent carding and spinning procedures, making the final shape of the product undetectable.

On the other hand, dyeing at later production phases, such as cloth, allows manufacturers to minimize overproduction of less popular colors and respond promptly to repeat orders for popular colors. Moreover, great care must be made to guarantee that the fabric or garment has a consistent shade level. Garment dyeing is also limited to clothing with simple designs.

In any dyeing procedure, it is essential to transport dye molecules from the dye liquid to the fiber surface and then diffuse them to the fiber structure’s interior. Because the dye liquor and the textile material must be moved relative to each other for optimal transfer, the system must be agitated.

This criterion is met in one of three ways by dyeing machines:

– Moving the textile material through the stationary dye liquor

– Pumping the dye liquor through the stationary textile

– Moving both the textile material and the dye liquor at the same time

The building of a dyeing machine must meet several basic parameters. They are often made of stainless steel to endure the chemical and physical conditions encountered in dyeing operations and preparatory processes, including desizing, scouring, and bleaching. The latter procedure uses hydrogen peroxide, which creates free radicals that attack and damage cellulose fibers if it comes into contact with iron or copper components in the machine. Stainless steel has the advantage of being inert to most process conditions while also being simple to clean.

Conclusion

Dyeing is used to turn raw textile materials into finished goods and greatly enhance the appearance of textile products. Textiles are dyed with a variety of dyes, processes, and machinery. Almost any type of textile material can be colored at any stage. Through its own process, each textile is colored with particular colorants. Synthetic dyestuffs have brought a broad spectrum of colorfastness and vibrant hues to the market.

Nonetheless, their toxicity has become a source of major environmental concern. Furthermore, water is utilized extensively in the textile industry’s manufacturing processes, primarily in the dyeing and finishing activities. Textile plant wastewater is among the most polluting industrial sectors, both in terms of volume and effluent composition. As a result, the textile dyeing business has needed to explore innovations, ecologically friendly remediation technologies, and alternative ecosystems.

Dear Kohan textile Journal, with the changing world dyeing, is also changing !! we are offering the know-how and ready-to-use Natural dyes with proper training with available dyeing setup without additional changes. Online and Physical training is available depending on the requirements. This is for any kind of natural fibre to be dyed in bulk or in a small scale. To know more please mail us at [email protected], Arun: +91 9099935019

Your article is very knowledgeable. Got a lot of information from this. Thanks for writing such articles. And thanks for sharing the article