History of Textile, garment and fashion industry in Africa

the African fabric industry is very old, and dates as far back as 5,000BC when ancient Egyptians began cultivating flax and weaving it into linen. An ancient pottery found at Badari shows an ancient depiction of a loom dating back to this period, while a 12th dynasty image from the tomb of Khnumhotep shows weavers using a horizontal loom (ca 2400 BC).

Moreover, pyramids, sculptures, and hieroglyphs clearly show all Egyptians clothed. the Dutch textile company VLISCO has been installed in Africa, more precisely in Togo, since 1846.

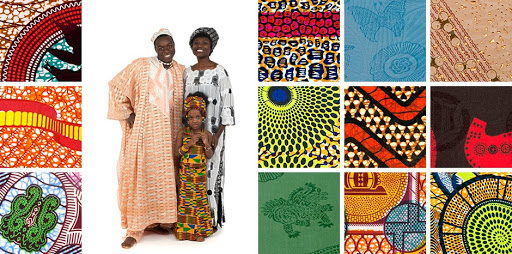

Vlisco has been designing and manufacturing distinctive fabrics loved by African women since 1846. The specially crafted fabrics – Wax Hollandais, Super-Wax and Java – continue to be made with time-honoured methods and materials in Helmond, the Netherlands.

African Growth and Opportunity Act (AGOA)

The renewal of the AGOA expected to give a strong impetus to African textiles and garment in Africa shipments to the U.S., as some Turkish textile manufacturers eye Kenya and Ethiopia for manufacturing operations, but African countries urgently need to upgrade infrastructure and simplify customs procedures

African textiles and garment industry is optimistic that its shipments to the United States, the world’s biggest market for such products, will surge following the 10-year renewal of the African Growth and Opportunity Act (AGOA) – under the United States’ General System of Preferences that allows duty-free imports of a wide range of African products, which was signed by President Barack Obama on June 11, 2015.

This is also driving many Turkish, Indian and Chinese textile companies to African countries, particularly Ethiopia and Kenya, to not only flee the rising production and labor costs at home but also to avail of the duty-free exports under the AGOA to the United States.

African textiles and garment industry

Conversations with textile exporters in the Kenyan capital Nairobi vindicate the growing optimism among African shippers. U.S. importers of African textiles and apparel were also optimistic, as was evident at the last TexWorld USA show held in New York where many buyers welcomed the AGOA’s renewal, which would create a win-win situation for both U.S. importers and sub-Saharan African shippers.

Nairobi-based J.C. Mazingue, a trade advisor and a contractor for USAid, told Daily Sabah that the AGOA would provide African shippers duty-free access to 8,000 products in the U.S. market, including almost all the textile and apparel products.

“The AGOA renewal will boost shipments of textiles and apparel to the United States, which for Africa is the world’s biggest market,” Mazingue said, adding that the AGOA will also motivate African and foreign companies to invest in capacity.

African textiles and garments in Africa

Kenya has emerged as Africa‘s largest apparel exporter, followed by Lesotho, Mauritius and Ethiopia. The Ethiopian government has identified textiles and apparel as a priority industry.

East Africa, according to Mazingue, has become the continent’s sourcing hub for textile and garment products in Africa. Ethiopia, Kenya, Lesotho, Madagascar and Mauritius are well-positioned for this.

But an obstacle to future growth is African countries’ anachronistic infrastructure that can impact the continent’s export trade. Mazingue believes that “generally, energy costs need to go down, transportation and logistics need to improve.”

But Mazingue underscored the “strategic advantage” accruing to textile and apparel manufacturers in Africa because of the availability of the cotton crop, cultivated mainly in the African cotton belt comprising Zimbabwe, Malawi, Ethiopia, Kenya and Egypt.

Cotton has become an important factor for Turkish companies. Turkey itself is one of the 10 leading cotton-producing countries and the fourth-largest consumer in the world. The country is, after India and Syria, the third-largest producer of organic cotton with a share of 3.4 percent, and Turkey’s clothing industry is the seventh-largest in the world and the third-largest supplier to the European Union.

Nonetheless, developments in neighboring Syria create uncertainty for Turkey’s cotton sourcing because three-fourths of cotton production in Syria is said to be controlled by DAESH. According to Turkish textile exhibitors at international trade shows, Turkey is no longer buying cotton from Syria. But it is a fact that the more than four-year war in Syria has led to a sharp decline in cotton production in Syria whose annual production today has fallen to 70,000 tons down from some 600,000 tons before the outbreak of the civil war.

African Textiles industry welcome to New Investors

African countries are particularly keen to attract job-creating investors, who are even given incentives for such purpose. However, incentives differ from country to country and are given on a case-by-case basis. According to the Nairobi-based East African Trade and Investment Hub (EATIH), textiles and apparel account for some 90 percent of exports from sub-Sahara African countries to the United States.

The bulk of exports is shipped by sea, but small quantities needed for seasonal purpose or last-minute ordering are also shipped by air, as Ivo Seehann, Lufthansa-Cargo’s Nairobi-based general manager for Kenya and East Africa confirmed.

African textile companies that are eager to take advantage of the rising demand in the U.S. for textiles and apparel products and also benefit from AGOA’s duty-free imports are establishing multiple textile plants. Mombasa Apparel, an AGOA-supported company, launched its fourth textile factory in November 2014 on the coast of Kenya while Taiwan’s New Wide Garment, which already has eight factories in Kenya, Lesotho and Ethiopia, plans to further expand its African operations.

Despite the AGOA duty-free privilege, not all African countries have been able to substantially increase their textile and apparel exports. Kenya, Lesotho and Mauritius account for much of apparel exports under the program. In 2014, Kenya exported $423 million worth of apparel to the U.S., followed by Lesotho with $289 million, Mauritius $227 million and Swaziland $77 million.

According to a report by the McKinsey management consulting firm, Ethiopia and Kenya in particular have the potential to become bigger players in garment manufacturing. Some European companies, including H&M, Primark and Tesco, have been sourcing their garment needs from Ethiopia, and that shows the quality of fashion industry in Africa, but other countries have also been supplying substantial quantities of apparel.

Inadequate infrastructure and cumbersome customs procedures

While Ethiopia offers cost advantages, Kenya boasts higher production efficiency, but both countries face challenges such as poor infrastructure, cumbersome customs procedures, a dearth of technical and managerial talent and low levels of social and environmental compliance.

African textiles and apparel exports to the U.S. could potentially quadruple to $4 billion over the next decade through the renewal of the AGOA, creating 500,000 new jobs, as Gail Strickler, assistant United States trade representative for textiles and apparel, said before the AGOA’s extension.

U.S. clothing imports from sub-Saharan countries in 2014 reached $986 million, up nearly six percent over 2013. However, African countries tend to lag behind in productivity, quality and product range, as Joseph Nyagari, an official at the Nairobi-based African Cotton and Textile Industries Federation (ACTIF), recently told journalists.

However, transportation costs are also not consistent. According to the 2015 East Africa Logistics Performance Survey, the cost of transporting a ton of goods through the northern corridor that runs from Mombasa, Kenya to Kampala, Uganda has declined from $ 3,400 to $2,500 over the last five years. On the other hand, the cost of using the central corridor from Dar-es-Salaam, Tanzania to Kampala nearly doubled over the same period to $4,500 in 2015 from $2,507 in 2011, making the central corridor twice as expensive as the northern one.

But leaders of Kenya, Rwanda and Uganda are working to make the port of Mombasa and the northern corridor more efficient and have helped reduce clearance costs. The three leaders have also committed to speedily upgrade infrastructure connecting their countries, including the standard gauge railway and Kenya’s Mombasa port.

Average clearance time for imported cargo at the Mombasa port dropped from eight days in 2011 to four in 2015, while it takes up to nine days to clear goods at the Dar-es-Salaam port.

Tanzania and Kenya are in a race to quickly develop their ports with both vying to become the region’s main transport hub, connecting other landlocked countries like the Democratic Republic of Congo, Rwanda, Burundi, Uganda and South Sudan to their ports.

While Tanzania is constructing a new port in Bagamoyo that will have capacity to handle 20 million containers per year, compared with Dar es-Salaam’s installed capacity of 500,000, Kenya is constructing a bigger port in Lamu under the Lamu-Port-Southern Sudan-Ethiopia (LAPSSET) transport corridor project.

Meanwhile, the second phase of Mombasa’s container port construction in Kenya is expected to start in early 2017. The Mombasa port has emerged as East Africa’s main gateway for sea trade connecting the East African hinterland to the world. The port’s construction, costing some $213 million, according to the Kenya Port Authority, will create an additional capacity of between 470,000 and 550,000 20-foot equivalent units (TEU). This will be followed by a third phase Entailing construction of a 300-meter-long berth and adding another 450,000 TEUs. The ongoing work on phase one should be completed by February 2016.

According to local forecasts, annual container throughput is expected to rise from 1.01 million TEUs in 2014 to 1.12 million this year. It is expected to further grow to 1.8 million and upward to 3 million TEUs between 2016 and 2030.

The future of the African textiles & fashion industry in Africa

While labour costs are competitive in a wide range of African countries compared to Asia, especially with costs in China growing rapidly, they lack training, both at middle management and operator level, they cannot benefit from economies of scale like China or India and corruption is still important.

The African textiles & fashion industry in Africa failed to industrialise on a large scale although in theory, the conditions were good. There are good examples of industrialization, even if on a lower scale then in Asia. Further industrialization of the African textiles & fashion industries to satisfy growing global consumption of clothing, home and technical textiles can happen in Africa.

But it will require an important, consistent and long-lasting political commitment and the vision to implement the right policies. If the textile & clothing industries in Africa are to flourish, it requires political will in both North and South.

I was looking for an article about the African textile industry and I really glad to get this.

Hi there,

I’m from a garment textile manufactoring company called Winitex Sdb Bhd from Malaysia. We are the linen supplier of choice too many of the finest hotels and retaurants in over 60 countries. Established in 1973 as a Japanese/German/Malaysian joint venture with high quality fabrics in intricate designs and colours worldwide. which includes yarn dyeing, weaving, embroidery and hemming. All the process take place in our medern manufactoring facility in JOHOR MALAYSIA and goods are expport worldwide.

i would like to get know the traders or direct sales from african textile.

Thank you.