December 9, 2020 marks the 80th-anniversary date of the Swissmem Textile Machinery Division. Stäubli, a member of Swissmem since January 1897, was among the founders of this section, dedicated to the textile industry.

The section was established during very difficult times, World War II, but has achieved success for both partners:

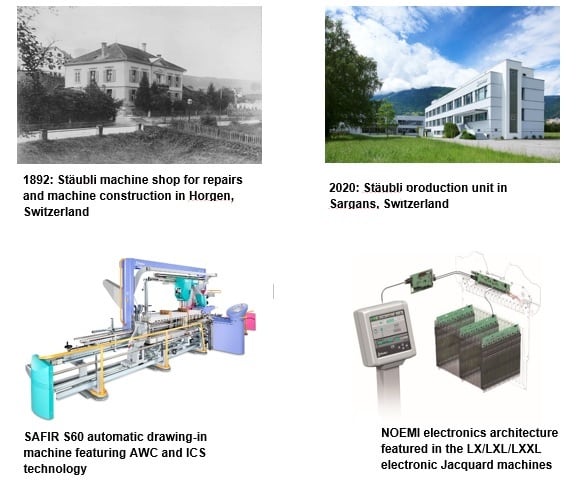

Today the Swissmem Textile Machinery Division is celebrating its 80th anniversary, and the Stäubli Group, as a founding member headquartered in Switzerland, enjoys worldwide renown as an innovation driver in textile mechatronics.

Remaining forward-looking and optimistic – and continuing to innovate during the present time in which people and businesses everywhere are struggling with a global crisis – are values that have been intrinsic to the Stäubli Group since the very beginning. Stäubli has always seen crisis and difficulty as a chance to think out of the box and to embrace new opportunities.

In 1940 the Stäubli family took part in the founding meeting of the Textile Machinery Division of the Swissmem association. Goals of this Textile Machinery Division were to secure supplies of raw materials, develop international relations, to approach markets in a united and effective way, and to continue making high-quality products in Switzerland and selling them throughout Europe and the rest of the world, even during difficult times.

The division has been globally promoting Swiss textile machinery in recent years with the slogan ‘Innovation: it’s in our DNA’. At Stäubli, the innovation gene dates back to 1892 and is abundantly evident today in the 500-some R&D engineers working in the Group to invent, redesign or improve Stäubli mecatronics solutions and thereby bring further benefits to Stäubli customers.

In their united quest for excellence, the various Stäubli teams bundle their expertise, long-term business experience, and the input of sales and technical teams who collaborate closely with customers and thus learn the real needs of the weaving mills and the markets. This rich combination results in a diversified product portfolio that meets the requirements of any woven application and covers the needs of any weaving company.

Stäubli also goes a step further: The company’s solutions support market trends, help to shape the industry, and provide the flexibility to adapt to future changes and challenges. Ingenious features and technologies, robust high-quality construction, comprehensive services, and spare parts availability even years after delivery make Stäubli solutions an essential part of modern weaving mill operations around the world.

Standard-setting technologies in weaving preparation and shed formation

Stäubli sets worldwide standards in the weaving industry. Prime examples are Active Warp Control (AWC) and Initial Condition Settings (ICS), applied in the company’s SAFIR automatic drawing-in machines. AWC enables automatic supervision and management of yarn types and colors during automatic drawing in. ICS represents state-of-the-art technology for efficient style and warp changes, enabling easy startup after style change with specific yarns, such as hairy or technical yarns.

These and other leading-edge technologies help to optimize the process flow within the mill and greatly enhance operational performance. The SAFIR range of automatic drawing-in systems offers two machinery concepts (one stationary and one mobile) and offers a choice of four machine models. These systems efficiently process not only standard yarns, filaments and effect yarns but also technical yarns such glass fibers for fine filter applications.

In the Jacquard weaving sector, Stäubli is the leading provider of weaving equipment for airbag and large-format weaving. The LX/LXL/LXXL Jacquard machines are available in many formats, with up to 25,600 hooks, and formats of up to 51,200 hooks can be achieved by combining two machines. These machines feature NOEMI, a new-generation electronic control system that sets a new standard for reliability in high-speed weaving.

The electronics architecture of NOEMI boasts a reduced number of connectors for extremely stable data transmission. The machines offer good operation. Mills that use an LX Jacquard machine combined with individually adapted Stäubli Jacquard harnesses have a reliable and highly efficient solution with a single purpose: producing high volumes of first-quality fabric with minimum downtimes.

Today’s innovations tomorrow

The Swissmem Textile Machinery Division will celebrate its next future milestone in 2030, at which time we will certainly look back on 2020, a year that will mark history books due to the pandemic which has devastated individuals and businesses around the world. To face this crisis, mankind has been called upon to adapt and remain flexible, and businesses have been challenged to innovate.

The Stäubli Group is determined to meet this challenge by providing flexible and reliable solutions for long-term use and by driving innovation further, always with one goal in mind: to provide modern and market-oriented solutions for the textile industry and thereby equip the industry for sustainable performance and achievement.