The RX circular loom series is produced at the Starlinger plant in Taicang/China specifically for the Southeast Asian market. This series is now extended with the RX 8.1, a circular loom that is particularly suited to the production of lightweight fabrics for 1- loop FIBCs, tarpaulins as well as geo- and agrotextiles made of PP, HDPE, and PET. In combination with the RX 6.0, RX 6.1, and RX 8.2, Starlinger Taicang now offers the ideal circular loom for every fabric width.

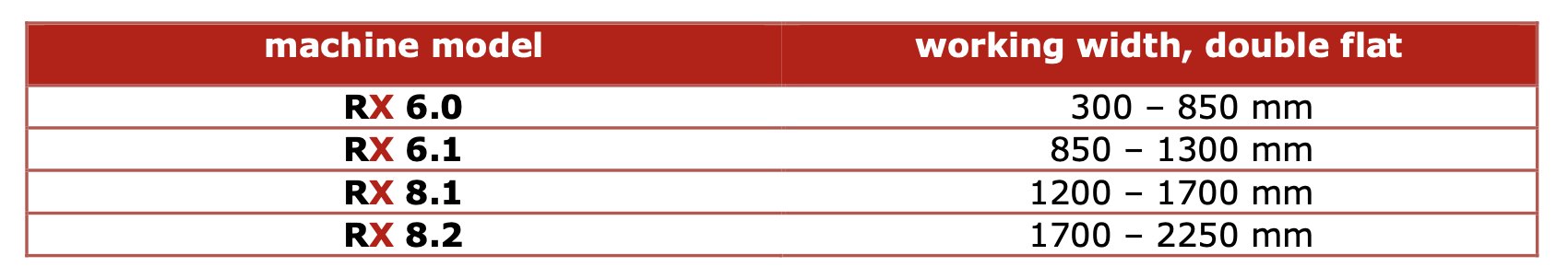

The new Starlinger circular loom RX 8.1 produces fabric with a width of 1,200 –1,700 mm, which is an ideal match for 1-loop FIBCs, tarpaulin fabrics as well as geo- and agrotextiles. The model completes the RX series, which now covers every working width between 300 and 2,250 mm.

Like all models of the RX series, the RX 8.1 is equipped with numerous technological advantages. Due to its special reed and shuttle design, the machine does not have any sliding parts that would require lubrication, and thus leaves no traces of oil on the fabric. This property allows for the optimal adherence of the coating to the fabric and eliminates concerns regarding the use of the fabric in food applications. Moreover, the RX 8.1 produces fabric of highest quality at lowest production cost per square meter, as the production speed of 800 picks/minute is high while the number of warp breaks is low. Other advantages are the machine’s user-friendliness, the energy-saving motors as well as a low noise level.

The machine will give its official debut at the plastics exhibition Chinaplas in 2021, as this year’s event has been cancelled due to COVID-19. In the meantime, prospective clients will have the opportunity to visit the Starlinger factory in Taicang for live demonstrations of the RX 8.1. The standard execution of the machine with single inlet will show the production of tarpaulin fabric with a double flat width of 1,500 mm and a weight of70 g/m2. A second machine will be equipped with double inlet and a gusseting device, which are available as options, and will produce fabric for 1-loop FIBCs with the same width, but twice the fabric weight (140 g).

Another attraction in Taicang is the RX 6.0 L: On this 6-shuttle circular loom, a PE liner is inserted into the woven fabric tube and attached to the plastic fabric. This process is performed fully automatically in the production process and allows the use of the fabric in sensitive applications such as food packaging.