The South India Textile Research Association (SITRA), Coimbatore, with more than 6 decades of research expertise, has developed a breakthrough technology for greener reduction of indigo dye during dyeing process labelled as GRIN – Green Reduction of Indigo Dye. The significance of the technology is that it does not call for any additional capital investments.

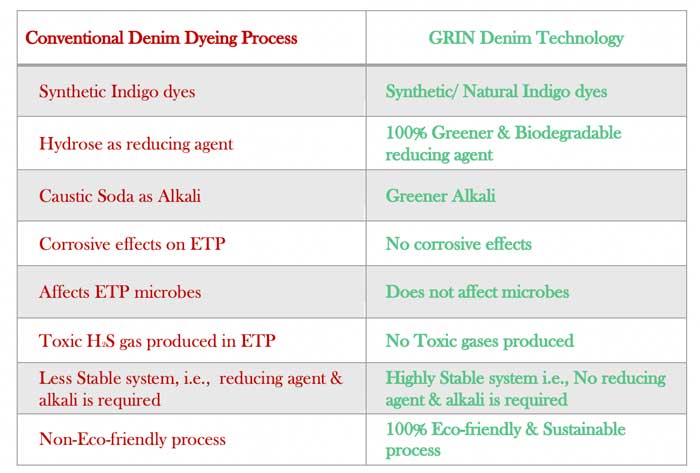

In most industrial indigo dyeing processes, sodium dithionite (hydrose) is used as an agent since it has a powerful reducing property. However, it leads to generation of non-regenerable oxidation products and results in various problems in the disposal of the dye bath and the washing water. Till date, no commercial green and organic indigo dye reducing technology is available globally for replacing sodium dithionite & sodium hydroxide (caustic) in all areas of vat dye applications.

“Indigo denim production is known to consume enormous quantities of water and requires hazardous reducing agents and alkali. No commercial technology has so far been established to replace sodium dithionite as a reducing agent and caustic for dyeing with vat dyes. SITRA’s ‘Green Reduction of Indigo Dye (GRIN)’ denim technology is the first internationally commercial and viable technology for natural or synthetic indigo dyed denim production for ‘zero pollution’, said SITRA in a press release.

Under the sponsored project titled, ‘Development of Eco-Clothing by Greener Reduction Process of Natural Indigo Dyes’ by the ministry of textiles, Government of India and with contributions from its industrial partner, K G Fabriks, Sipcot, Perundurai, the research team from the chemistry division of SITRA has developed a process using a 100 per cent greener and biodegradable reducing agent and a green alkali for bulk production in continuous yarn slasher dyeing machines. The biggest advantage of this technology is that it can be used for the manufacture of denims using both synthetic indigo and natural indigo dyes.

The new process eliminates hazardous wastewater completely by replacing the sodium dithionite or hydrose and caustic by using a green reducing agent and a green alkali. The process is not only pollution free but prospects for improved process stability, especially for vat dyes.

KG Fabriks, in collaboration with SITRA, will be launching ‘Nature’s Blue’-True Sustainable Denim at Weaves exhibition at Texvalley, Erode, using natural indigo with GRIN denim technology developed by SITRA. SITRA is in the process of filing a patent for the said development.