Saurer Group’s innovations that excited the textile world in June 2023 will soon be presented live in Shanghai to textile experts from the Asian market. Saurer is looking forward to welcoming customers at the ITMA Asia + CITME on booth A 47 in hall 8 to showcase all the latest innovations.

The wide range of Saurer’s new machines and trendsetting ideas will once again shape the future of the textiles. Since 1853, Saurer has been driving the transformation of the textile industry, supporting it in the areas of sustainability, digitalisation, and automation.

Saurer Group offers high-quality, technologically advanced, and customer-specific automated solutions for staple fibre processing from bale to yarn. The portfolio also includes intelligent and economical twisting and cabling machines for staple fibre, tire cord, carpet, glass filament and industrial yarns.

Technology support is an important part of Saurer’s service and customers benefit from two well-equipped technology centres in China where they can be present when their materials are processed.

Live exhibits on the booth: Autocard SC 7M, Zinser 51 ring spinning machine, BD 8 and Autocoro 11 rotor spinning machines, Autoairo air spinning machine, and the new PrimeTwister. Texparts components, upgrades, and updates and the Fibrevision product range will also be on display.

Autocard SC 7M

The new Autocard SC 7M is the result of a brand-new development concept, with a functional and modern machine design. With the same quality standards, the card offers an impressive 20% higher productivity thanks to a larger carding area of over 4m2.

Customers benefit from higher material utilisation rates thanks to advanced waste detection and automatic settings. These features are especially beneficial when producing recycled fibres. The automatic adjustment of the revolving flats gauge and the pneumatically assisted piecing-up technology simplify the operating process, reduce the mill’s manual labour, and significantly improve production efficiency.

BD 8 – Pioneer for recycling and waste spinning

The BD line of semi-automatic rotor spinning machines has been recognised and established in spinning mills worldwide for over 50 years. They are the benchmark for sustainable spinning and ideal partners in the field of recycling and waste spinning.

The new BD 8 is supplied with automatic doffer units (DU). The doffer changes the packages without interrupting the spinning process. Equipped with up to four doffers, the BD 8 provides sufficient doffing capacity even for coarse yarns. Double-digit energy savings and yarn quality improvements can be achieved with the new suction device Twinsuction being installed at both machine ends.

The unique Digital Joint Spinning piecing technology enables fast, fully automatic machine start-up. High production losses due to power failures are a thing of the past. Take-up speeds of up to 230 m/min, an LED operator guiding system to increase machine efficiency, ergonomic machine operation and the flexibility offered by the Multilot, Pilotgroup and Fancynation functions enable Saurer customers to react flexibly to the demands of the yarn market.

BD 480 Plus – with new automatic doffer

The needs of the textile industry are Saurer’s top priority, therefore the semi-automatic rotor spinning machine BD 480 Plus is now available with an automatic doffer for package change. With 2 automatic doffer units (DU), customers can benefit from increased efficiency and a reduction in manpower.

Autocoro 11 rotor-spinning machine

The new, fully automatic Autocoro 11 rotor-spinning machine is the 4th generation of Autocoro with individual drive technology, which is already operating reliably with more than 1 million positions worldwide. The Autocoro 11 is making production at the same time sustainable and cost-effective. It saves up to 10% energy compared to its predecessor, the Autocoro 10. Investment in new technology pays off: Autocoro’s energy consumption has been reduced by 38% over the last 15 years.

Equipped with the Recycling Xtreme rX edition, the new Autocoro generation is tailor-made for recycled fibres. Special dirt-repellent surfaces are in use for the rX yarn guides, opening rollers and fibre-beard supports. The new patented rotor cleaning technology keeps the rotor groove clean, and the new extraction system removes waste even more efficiently.

The Synchropiecing 60 technology now increases the piecing capacity of Autocoro 11 by 65%, allowing to maintain high efficiency even with difficult materials such as mechanically recycled fibres. In addition, the Autocoro 11 shines with more powerful automation and with a new LED-supported operator guidance system, which further enhances the high productivity of the Autocoro 11.

Autoairo air-spinning machine

The Autoairo sets new benchmarks for producing high-quality air spun yarns named Belairo. These yarns have high pilling resistance and are very durable. The spinning process itself also sets new standards. Compared to combed ring spun yarn, the production of Belairo yarns uses less energy, less manpower, fewer machines, and less production space, which means lower building and air conditioning costs.

Saurer Group has combined this resource-saving spinning technology with an advanced automation solution: simultaneous piecing with Synchropiecing on each spinning position. Thanks to the digital control of the autonomous spinning positions and new smart features, yarn quality is guaranteed. Saurer’s Autoairo air-spinning machine offers the flexibility to process different fibres, even simultaneously, thanks to Multilot: cotton, polyester, viscose as well as new chemically regenerated fibres.

Autospeed roving frame

The energy-efficient Autospeed roving frame with automatic doffer allows spinning mills to be less dependent on the availability of skilled personnel and at the same time increases the quality of the roving. The Autospeed roving frame with up to 240 spindles saves up to 20% of energy compared with the previous model, while doffing takes less than 2 minutes. Autospeed can be combined with the automatic bobbin transport system, with Roweclean, the automatic tube cleaner and the Rowestore empty tube magazine.

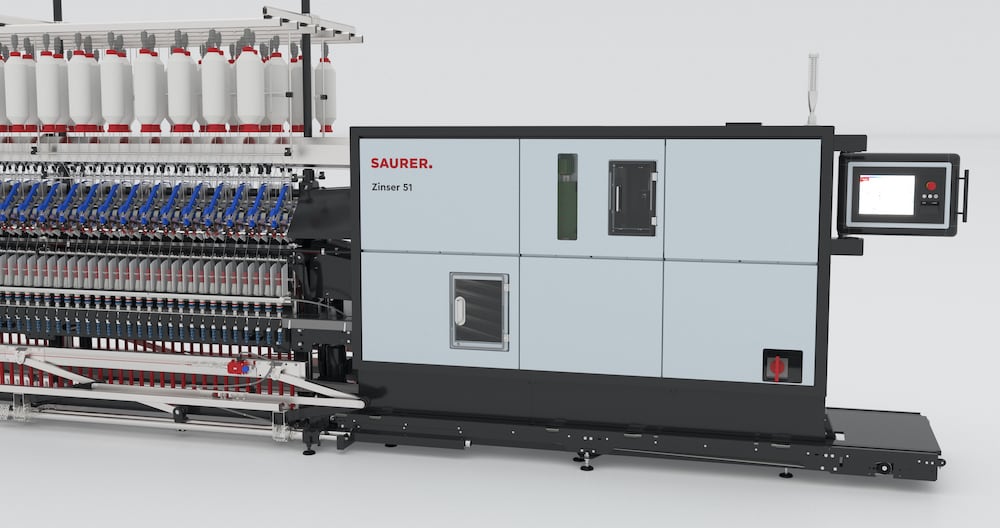

Zinser 51 – Saurer’s new ring-spinning machine generation

At the ITMA Asia, Saurer presents the Zinser 51 ring spinning machine series for the first time. The series is offered as a ring-spinning or as a compact-spinning machine. The Zinser 51 sets new standards for sustainable spinning, maximum economy, optimised user-friendliness, and flexible automation solutions in ring spinning.

The newly designed suction system, combined with proven energy-saving features, achieves high energy savings. The new NSD-i drafting system monitors all drives to ensure consistent yarn quality values over the entire length of the machine. This reduces operator workload and speeds up a lot of changes. The innovative and robust intermediate drive Flexidriver NFD ensures consistent yarn quality on extra-long machines.

High-end components such as the Texparts Eshape spindle and Spinnfinity, ideal for high-speed spinning, enable top speeds of up to 30,000 rpm. To produce high-quality compact yarns, the new Zinser 51 can be equipped with reliable compact units Impact FX and Impact FX pro.

ZI 451 worsted compact-spinning machine

The ZI 451 worsted compact-spinning machine for wool fibres and its blends with acrylic, silk and cashmere fibres impresses worsted spinners with its high flexibility and profitability. Most of the finest woollen suits are made from yarns spun on the ZI 451, a very popular machine in the long staple fibre spinning industry worldwide.

PrimeTwister – the new two-for-one twisting system

Saurer’s new PrimeTwister, the two-for-one twisting system for staple fibre yarns, offers high flexibility thanks to its wide yarn count range. Energy consumption is reduced by up to 40% thanks to the unique spindle geometry and spindle bearings.

In addition, the high quality of the yarn guide elements ensures consistently high twist quality. The new machine design requires less production space, thus reducing building and air-conditioning costs. Minimal maintenance and service requirements as well as reduced assembly and installation times complete the machine concept. The PrimeTwister is an economical and future-proof investment. The unbeatable price/performance ratio combined with Saurer’s world-renowned reliability guarantees a high return on investment.

CompactTwister

The advanced spindle and drive design of the CompactTwister offers low power consumption and short doffing times combined with a low yarn breakage rate. Balloon limiters, energy-saving spindles, optimised drives, and many other features on Saurer’s twisting and cabling machines result in significant energy

savings. Twisting recycled yarns increases the strength for further downstream processing and extends the yarn’s range of application.

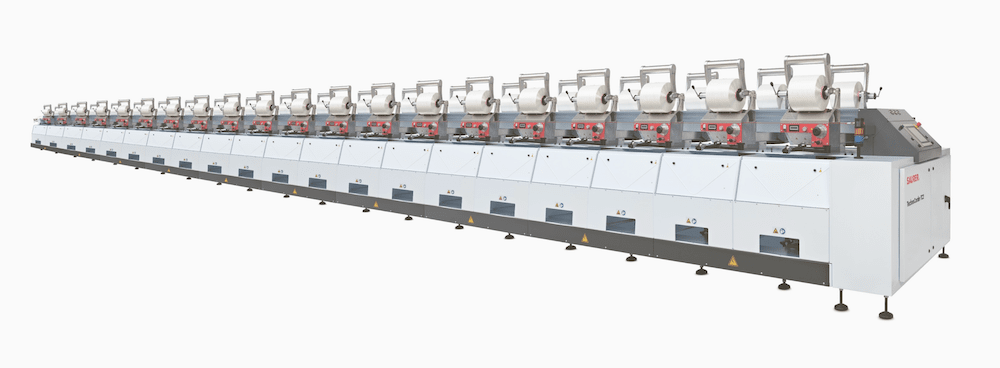

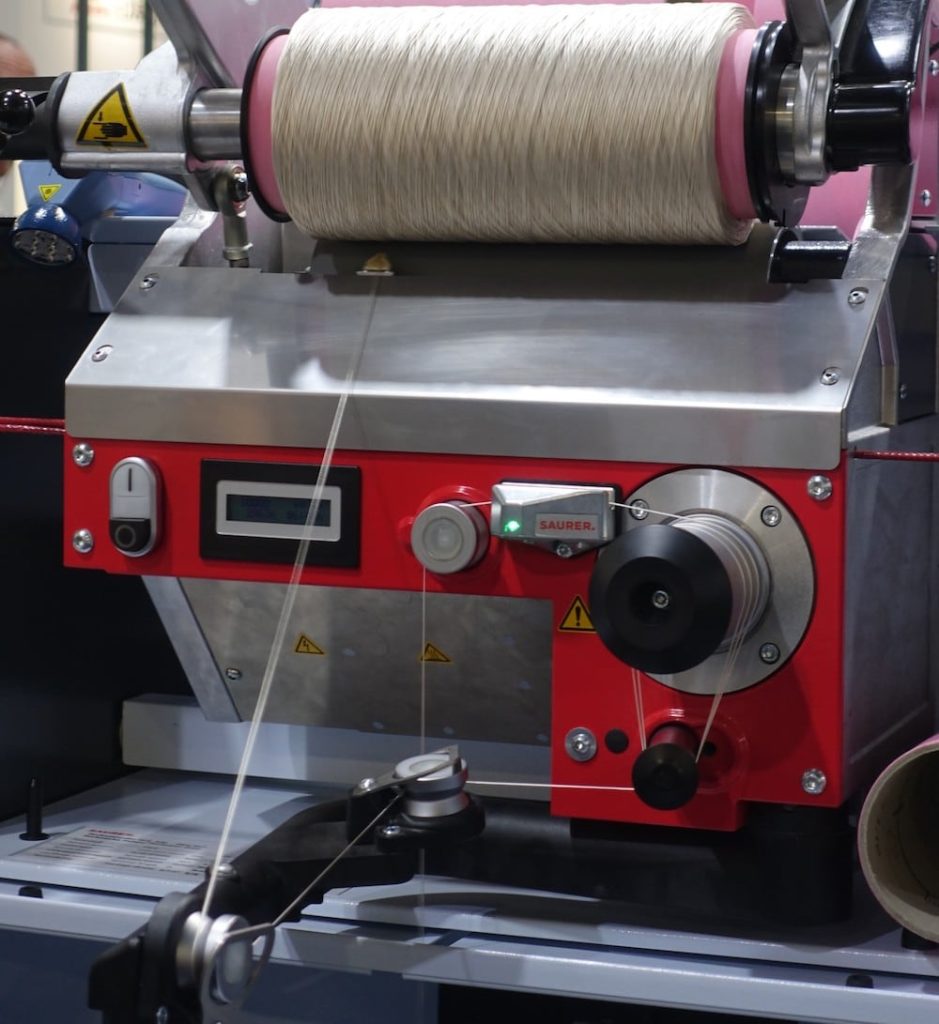

TechnoCorder TC2 Plus

The TechnoCorder TC2 Plus can process a wide range of yarns and offers a yarn lubrication device to ease further process steps. The latest feature, PreciWinding, (TC2 Plus) features a newly developed take-up area for producing twist packages of a very high quality.

CarpetCabler/CarpetTwister 1.12

Among its many impressive features, the CarpetCabler/CarpetTwister 1.12 offers an energy-saving spindle range and central computer-controlled balloon adjustment. With the new series, customers will be able to meet the demanding requirements of an ever-changing market with confidence and reliability.

Fibrevision – synthetic yarn monitoring for DTY, IDY, BCF and POY

Fibrevision’s yarn quality monitoring and grading systems minimise waste from the start by detecting yarn faults early, recording quality data and optimising production. This is essential for both virgin and chemically recycled synthetic fibres. The use of recycled polymeric material can lead to unpredictable defects during the manufacturing process. It is becoming increasingly important to monitor and grade yarns as quality requirements increase and more recycled material is used.

Fibrevision’s Total Quality System (TQS) covers a wide range of yarns from polymer spun yarns (POY, FDY) to texturised yarns (DTY). Depending on the application, industry and requirements, a variety of quality sensors with different methods are used: from tension monitoring (Unitens), optical monitoring (FrayTec FV2) and oil monitoring to looking for defects in broken filaments, interlacing and yarn fineness. Fibrevision’s systems can be used in-line on the machine, in the laboratory or as at-line instruments for product development.

Texparts – the world of components

The Texparts product line supplies high-quality components for ring and rotor-spinning that ensure the highest yarn quality and maximum productivity. The newly designed PK 1580 drafting system for roving frames is ergonomically designed and easy to use. Fast and precise load adjustment allows to processing of a wide range of fibres and is also of advantage for recycled fibres. With the new RB 105 complete rotor-bearing system, mills can upgrade existing rotor-spinning machines to a high-performance solution.

The new Texparts Eshape spindle has a reduced wharves diameter of 17.5 mm. Combined with the Spinnfinity zero underwinding system, Escape enables remarkable energy savings of up to 6%. Thanks to an adapted yarn cutter, Spinnfinity is now also available in a new version for worsted and coarse yarns. Texparts offers a wide range of high-quality rings and travellers which is continuously extended to meet the needs of spinning mills.

Sun – Service Unlimited

Sun – Service Unlimited offers solutions for a long and sustainable service life for installed Saurer machines. Customers can make existing machines fit for processing recycled fibres – either with updates and upgrades, clever preventive maintenance services or with technology kits including original Belcoro and BD Value Line spinning components for nearly every textile application. There are numerous solutions available to increase the quality, performance, and profitability of spinning mills. Saurer’s customer support experts will be on the booth to explain the benefits of the various solutions.

Automation for spinning and twisting

Automation plays an important role in the transformation of the textile industry. Saurer offers various automation solutions that enable textile mills to reduce labour costs, optimise material flows, shorten lead times, and increase productivity.

Saurer’s innovative automated guided vehicles (AGVs) for spinning and twisting improve mill productivity and reduce dependence on staff availability. With tailor-made, customer-specific solutions, Saurer meets the growing demand for cost-effective automation. Besides automation inside the machine – doffing at roving and ring frames – Saurer offers various transport and package automation systems between the machines.

About Saurer Group

The Saurer Group, founded in 1853, is a leading, globally active technology company with a focus on machines and components for yarn production. As a company with a long tradition, we have always been an innovation leader. Today, the group is a solution provider for the textile industry. Saurer Spinning Solutions offers high-quality, technologically advanced, and customer-specific automated solutions for staple fibre processing from bale to yarn.

Saurer Technologies specialises in intelligent and economical twisting and cabling machines for tire cord, carpet, staple fibre, glass filament and industrial yarns, which allow customers to adapt flexibly to dynamic market requirements.

Automation Solutions provides textile mills with an array of labour-saving systems. With around 3,300 employees, the Saurer Group, with locations in Brazil, China, Czech Republic, France, Germany, India, Mexico, Singapore, Switzerland, Türkiye, the UK, the US, and Uzbekistan, is well equipped to serve the world’s textile centres. Saurer is listed on the Shanghai Stock Exchange (WKN: 600545).