New trends and technologies are shaping a new concept of urban life, which entails a profound change. In this sense, people’s relationship with their home will change radically, depending more and more on virtual assistants and interconnected devices.

The connected home is becoming a reality and, although the technology is already available in most cases, the great challenge consists in relating it to real consumer demand. It is undoubtedly a bet on the future that still has a long way to go, but currently there are some barriers, such as high prices, usability, doubts about security, and automation in the manufacturing process.

Through this R&D project, it is mainly intended to minimize this last fact, since embroidery technology will be used in the development of different smart textile solutions. It is a mature and efficient technology for the integration of sensors, actuators, interconnection and energy transport in a multitude of fabrics, as well as for the development of new technical textile structures with high added value.

Results obtained with the BRODER project

The main objective of the BRODER project is to carry out research in order to develop smart textiles with high added value through embroidery technology for home automation applications.

It will make it possible to improve the innovation capacity of the industry, thanks to research in the application of embroidery technology to obtain intelligent textiles in an automated way, a fact that is intended to represent a scientific and technological advance, both nationally and internationally.

- Development of textile antennas for wireless energy transfer.

- Development of textiles with the ability to detect distributed pressures/presence throughout a given area.

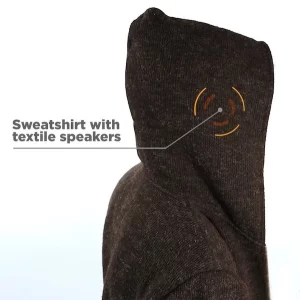

- Development of textile articles with the capacity to generate sound.

- Development of electronic sequins there is the capacity to incorporate any type of commercial sensor/actuator/connector into a textile in an automated manner.

Source: www.aitex.es