Interview with Mr Sedat Kumartasli / R&D Supervisor of Tasdelen Group Turkey

Taşdelen Group, which foundations were laid in Bursa Demirtaş Organized Industrial Zone, started synthetic yarn production in 1986 with the establishment of Polyteks A.Ş. company. In the following years, Taşdelen Tekstil A.Ş. and Sintaş Büküm Boya A.Ş. has been joined in the group.

1. Please give us more information about Taşdelen Group, its history and success story.

In this way, it has aimed to be able to respond to customer demands in a versatile way with it’s package dyeing and weaving units from synthetic yarn production and has become one of Türkiye’s leading polyester yarn manufacturers.

Polyteks, which is the first foundation of Taşdelen Group, has approximately 650 employees who adopts a clean production approach and apply it to all processes in it’s technologically advanced modern production facilities located on an area of 40,000 m2, exporting to 33 countries.

The way to survive in the industry and to make value-added production is through sustainable R&D and innovation; Since the way to make R&D process more systematic and efficient is to be an actual R&D Center, Polyteks R&D Center was established in 2017 with the approval of the Ministry of Industry and Technology.

Currently, the R&D Center is working on more innovative, more innovative and more environmentally friendly projects with a team of 26 qualified employees in different disciplines. Our company also supports it’s researchers academically and provides opportunities for both graduate and doctoral education.

With many firsts in Türkiye, Polyteks obtained a clean production perspective by protecting natural resources on the production of technical/smart textiles with the military, medical and sportive clothing by using our national resources. Polyteks has also multifunctional threadwork in it’s process. He also has preliminary studies on composite fibres, the restructuring of fibers with nanotechnology, and biodegradable fibers.

In addition to its innovative perspective, Polyteks also has a vision of clean production. Our company, which provides recycled polyester yarn services to its customers, has been producing sustainable products with the Global Recycle Standard Certificate (GRS) since 2018 and shows that they are traceable in the world.

2. What is your product range?

As Polyteks Tekstil, polyester, which is a synthetic yarn used in home textile, automotive, clothing, curtain, upholstery fabric, outdoor applications, garden furniture, sports and underwear etc. we offer our services in many other industries as well. In this sense, companies that have a large place in both domestic and foreign markets are our customers. We serve the textile industry with our standard and functional yarns.

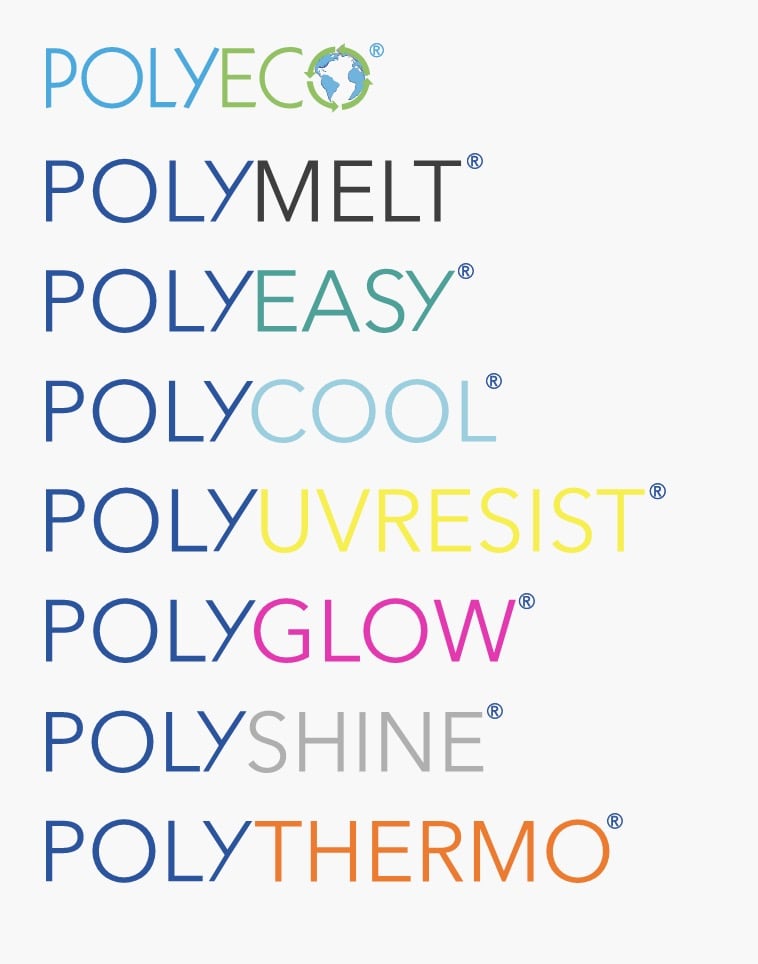

While producing semi-matte, glossy, micro, matte, chip-dyed FDY, highly elastic, air-textured and slub yarns in our standard qualities, functional yarn can be recycled, dyed at low temperatures, moisture-controlled, flame retardant, UV resistance increased, low-melting, hollow We produce fluorescent colored and soft touch yarns with cross-sectional structure, increasing body temperature with the effect of sunlight, high shine, different effects.

3. Can you tell us more about your functional yarns and this kind of yarn market?

We have a product portfolio for multifunctional recycled technical textiles. Even though its name is just beginning to be pronounced in the sector, waterless dyeing is one of the important techniques we have applied since the day we were established.

In this way, we make environmentally friendly, clean production. In addition, with our polyester yarn with low-temperature dyeing feature, we save energy and water and obtain value-added products with less cost.

By using biodegradable polymers in our production lines, we offer synthetic yarns with less environmental impact to the market. Thus, we integrate the sustainability development goals into our internal processes. We also carry out joint studies with different industries such as the automotive, defence industry, aerospace and aerospace industries, and to obtain hybrid yarns with composite materials.

4. What percentage of your product do you export to international markets? Tell us more about your export destinations and the demand in the export market.

Polyteks Tekstil meets the needs of the synthetic yarn market with its high production capacity. We have an important position in our country and in the world with our monthly production of over 3500 tons of POY, ecru and colored FDY, 3500 tons of textured, 500 tons of quilted and twisted yarn. Our export rate constitutes approximately 30% of our sales.

As in the domestic market, home textiles, clothing, outdoor applications, technical textiles, medical textiles, etc. We are used in fields and export to many countries.

While working with important customers in the foreign market, our company, which allocates 30% of our production to export, does our best to meet the expectations of our customers with the quality principle adopted and while serving to European countries, especially Germany, Sweden, Italy; We also export to Far East countries such as China, Vietnam, Bangladesh, Sri Lanka. With our export figures that we increase every year, we continue to work for cooperation with the USA, Russia and Belgium, which are in our target market.

5. How do you evaluate the textile industry and the yarn production industry in particular in Türkiye?

When we evaluate synthetic yarn production and Türkiye; Considering that the biggest producers of Europe and the Middle East are in Türkiye, the potential and capacity of functional and special yarn production is increasing gradually, besides classical conventional yarn production.

With the new investments made in Türkiye, the production of bicomponent yarn production technology, recycled polyester yarn production, FR yarns and functional yarns used in outdoor applications are increasing rapidly. Many companies create new markets for themselves by producing more specific yarns and increasing their profitability with value-added sales.

6. The Middle East and Africa are important destinations for textile products, how do you evaluate the textile and fashion industry in this region?

After the pandemic, the textile industry went beyond the usual markets such as Europe and America, due to the economic contraction and raw material prices, and set its sights on Africa and the Middle East in search of new markets. Considering the textile and fashion sectors in these two regions, it is certain that there is great potential.

At this point, we can say that the interest of the producers in Türkiye, especially Iran and Africa, in the Turkish market excites the sector. With the fairs and organizations held for this purpose, the desire to enter the market has increased considerably. It is aimed to create a large volume in the market by bringing together designers and manufacturers in the Middle East and African countries.

Market entry, marketing, distribution and sales channels will play an important role in this region, which has the most sophisticated market economy in Africa and the Middle East and has a unique culture synthesis and lifestyle.

7. We should rely more on sustainability and green products, how can we improve sustainability in the textile industry?

Sustainability has been on our agenda for the last few years, just as it is on the world’s agenda. We build our work on this and create our projects with an environmentally friendly product perspective. In almost many of our studies, recycled polyester is used.

We have a product portfolio for multifunctional recycled technical textiles. Even though its name is just beginning to be pronounced in the sector, waterless dyeing is one of the important techniques we have applied since the day we were established. In this way, we make environmentally friendly, clean production. In addition, with our polyester yarn with low-temperature dyeing feature, we save energy and water and obtain value-added products with less cost.

By using biodegradable polymers in our production lines, we offer synthetic yarns with less environmental impact to the market. Thus, we integrate the sustainability development goals into our internal processes. We also carry out joint studies with different industries such as the automotive, defence industry, aerospace and aerospace industries, and to obtain hybrid yarns with composite materials.