Kohan Textile Journal sat down with Rieter CEO Thomas Oetterli to deep dive into the big trends shaping the spinning industry and how spinners can turn them into their advantage.

-

Key drivers shaping the future of the textile industry globally

The spinning industry is by its nature highly competitive. The current environment shaped by rising costs, volatile demand and skills shortages will continue to put pressure on spinners for some time to come. Against this backdrop, the world belongs to those who can adapt quickly and cost-effectively to rapidly changing market trends. At Rieter, we believe that the best way to do this is through automation, digitization and artificial intelligence. This is why we design our entire technology portfolio around these technologies.

-

Major technological breakthroughs and innovations introduced by Rieter over the decades

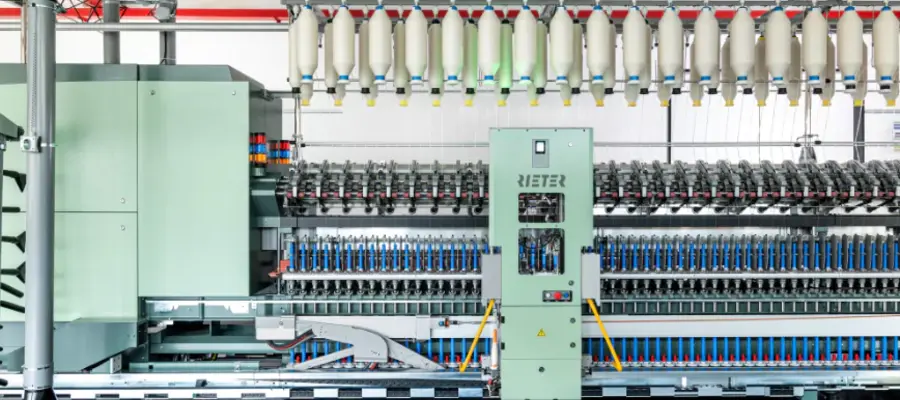

For sure, Rieter has been shaping the industry for generations, bringing to market many firsts that then become the standard. Examples include our OMEGAlap winding belt technology, compact-spinning technology, and the piecing robot ROBOspin.

We believe, however, that the best is yet to come: Our vision is the full digitization of spinning mills. ESSENTIALoptimize, the latest module in our digital spinning suite ESSENTIAL, represents an important step in this direction. ESSENTIAL analyzes data of the entire spinning mill in real-time and provides meaningful key performance indicators. We are building out ESSENTIAL with the help of artificial intelligence and data analysis to create an intelligent system that will further optimize spinning mill efficiency.

-

Rieter’s contribution to sustainable practices across the textile value chain

Rieter technologies minimize resource consumption in the spinning process while setting standards for economic efficiency and sustainability in the textile value chain. We develop state-of-the-art technologies for processing mechanically recycled fibers into high-quality yarns. Around the world, customers count on our recycling systems and the corresponding technology know-how so they can turn the industry’s sustainability trend into their growth opportunity. Rieter’s in-depth textile expertise also supports customers in the development of new yarns from fibers produced or recycled in a chemically sustainable manner.

-

Evolution of Rieter’s customer base and geographical footprint over the past decade and key growth markets

Rieter’s traditional markets in Asia, the Americas and Europe remain strong, and we are committed to equipping our customers there with leading-edge technology so they can stay ahead. The world’s textile supply chain, however, is shifting toward nearshoring. This trend is here to stay and opens up new opportunities in regions like Central America and Africa. At the same time, we see that traditional markets like Türkiye – which is close to Europe – are also ideally positioned to benefit from this trend.

-

Rieter’s support for Turkish spinners and weavers to enhance global market competitiveness

The Turkish textile and clothing industry enjoys an excellent reputation and ranks among the most important textile markets in the world. Well-known international fashion brands rely on the quality of the high-end products produced there. For 50 years, Rieter has been playing its part in shaping this fascinating and dynamic market. Turkish customers are highly innovative and pioneering, especially when it comes to automation and digitization solutions. We celebrated this important milestone at this year’s ITM in Istanbul.

-

Opportunities for Rieter in the Middle East and North Africa (MEA) region

Africa is an important market for Rieter, particularly in selected regions. This is most strongly reflected in our contract with the Cotton & Textile Industries Holding Company in Cairo, Egypt, which is designed to accelerate the modernization of the Egyptian textile industry. Here we are equipping textile factories with cutting-edge ring and compact-spinning systems. This initiative aims to diminish energy usage and to amplify production capabilities. The project fills us with great pride as we support this growing market in a sustainable and forward-looking way.

-

Latest Rieter technologies relevant for textile producers in the Middle East and Africa

Every mill owner, no matter where they are based, needs to explore how they can benefit from automation, digitization and artificial intelligence. At Rieter, we can help provide customized solutions that take into account the specific situation of the mill. Another area where the Middle East and Africa are uniquely positioned to add value is in sustainability.

-

Impact of AI and automation on the textile industry in labor-abundant countries like Bangladesh, India, and China

Automation and Artificial Intelligence (AI) bring opportunities for all. Automation enables using resources more efficiently while improving the quality of work. Our fully automated piecing robot ROBOspin, for example, pieces over 1 000 000 yarn breaks in mills around the world every week. As the repetitive task of piecing is left to machines, people can focus on activities that enrich their jobs and add value to the business.

AI meanwhile helps to minimize energy and raw material consumption. We are incorporating artificial intelligence into existing machinery, a case in point is our card C 81, where we have added intelligent sensors which set the carding gap to the ideal size and monitor contaminant content in real-time.