Interview with Mr. T.A. Motasim Billah / Manager (Printing) at Noman Group

Noman group was established in 1968 as a trading company, in 1975 company turned to the manufacturing of textile products. The group was founded by Md. Nurul Islam. It is the largest vertically integrated textile group of companies in Bangladesh. 1st industry of this group is Artex Fabrics Ltd.

1- First of all please let us know about Noman Group’s history and it’s success story in the textile industry.

In 1997 Zaber & Zubair Fabrics Ltd was incorporated with a mission to grow up as an internationally recognized home textile manufacturing company. In 2011 the group opened 6 textile factories, by that time company was operating 19 plants. In 2012 the group opened a towel factory. By 2015 the company operated 28 factories and another 5 new plants were under development. Total revenue crossed $1 billion in 2013 and is growing. The group have over 60000 employees in Bangladesh.

2- What is Noman Group’s range of products?

Noman Group produce all types of home textiles such as Duvet cover, pillow cover, bedspreads, bed linens, bed throw, bed sheet, quilt cover, comforters, bed cover, curtains, shower curtains, table runners, upholstery, aprons, kitchen cloth, napkin, table cloth, chair pads, rug, mat.

The group produces yarns, fabrics, denim and towel. Recently the group started manufacturing polyester & nylon filament yarn and microfiber fabric.

3- How do you evaluate the textile industry in Bangladesh in general? You can add any number, export-import figures and statistics and …

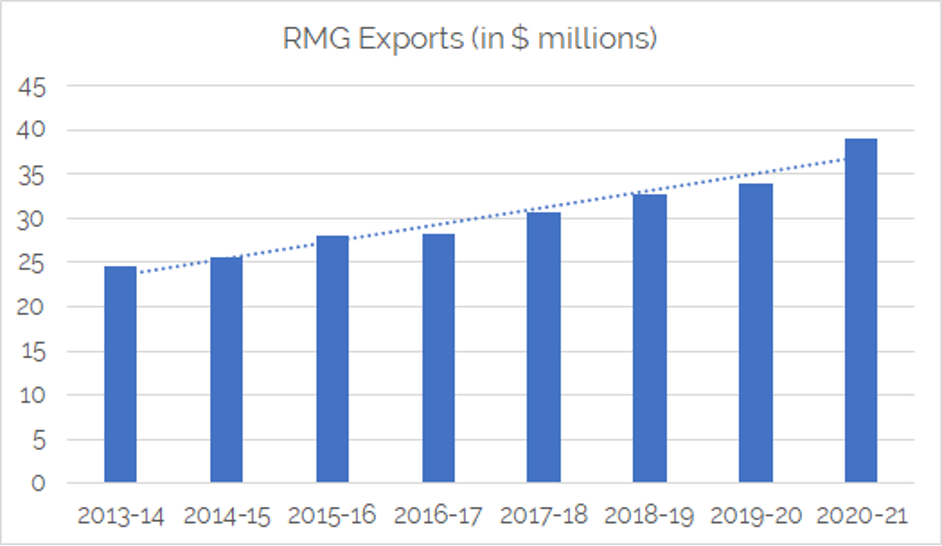

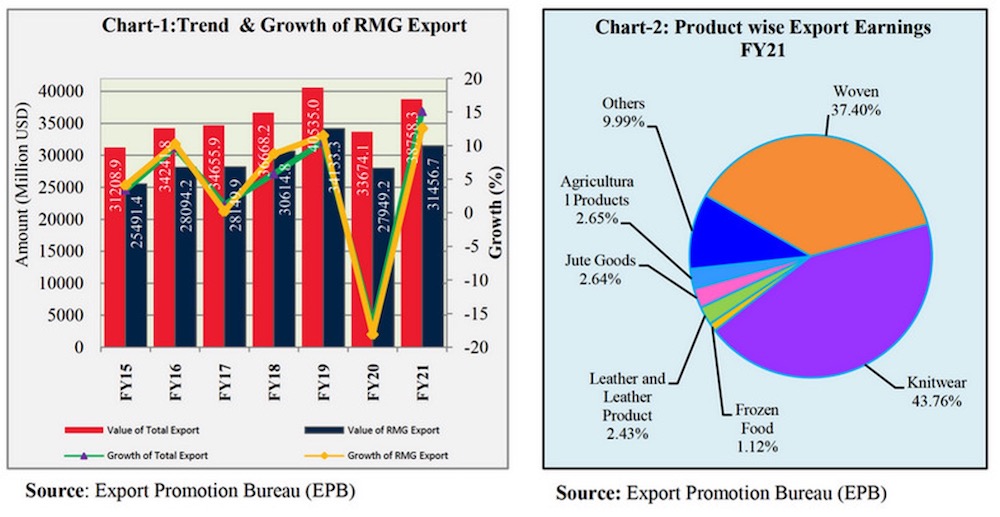

The textile and clothing industries provide a single source of growth for developing the economy of Bangladesh rapidly. Bangladesh is the world’s 2nd largest apparel exporter of Western fast fashion brands.

In 2012 Bangladesh’s garment exports to the US and Europe 80% of the country’s export income.

Bangladesh witnessed an increase of 35.47% to $42.613 billion in the last fiscal 2021-22 compared to exports of $31.456 billion in fiscal 2020-2021.

The government has set a merchandise export target of $58 billion for 2022-23.

4- How many percent of your products are exported to international markets and how many percent use in Bangladesh’s local market? Where is your main export destinations and countries?

Actually, Noman Group is an export-oriented company. According to our country’s retailers and wholesalers on demand, the group produces some items for our local market. Noman group experts more than 80% and less than 20% for the local market.

Noman group experts to European Union, United States, Japan and Asian countries.

5- As a textile printing expert how do you evaluate the digital printing market and investment globally and especially in Bangladesh? What is the pros and cons?

Bangladesh is fast growing in textile printing with Rotary, Flatbed & digital printing. Bangladesh has gained and ability to compete with any country in the world with All Overprinting (Screen Printing), but we are still so much behind in Digital Printing.

Recently, rapidly increasing digital printing accordingly. In 2015, 1st time digital printing was used for fabric printing by Beximco Group. At present, there are almost 25 digital printing factories. The world’s fastest digital printing machine MS Lario is in Bangladesh’s Robintex Group.

At present, we facing an order crisis of digital printing. If digital printing order is available in Bangladesh, in the future lots of company will invest in Digital printing.

Pros:

- Use of water is 90% less and electricity is 30% less than the traditional printing process. Because there is no need to wash screens by applying new colors.

- Required less manpower than traditional printing.

- In digital printing, there is no need to do any calculation of repeat measurement. The design of any measurement can be developed.

- No need of screen engraving and color separation, which process is cost-effective.

- Less wastage of dyes/inks and chemicals than flatbed or rotary screen printing.

- Lower fixed costs and lower sample costs are the top benefits of digital textile printing.

- Low capital investment.

If we compare digital printing machines with conventional Rotary & Flatbed that conventional can use 10-15 years with less maintenance cost but for digital it is not possible. If digital printing machines, spare parts and services become available and cost-effective, definitely this sector will be longer. As digital printing is globally environmentally sustainable than conventional printing. It’s business and investment will increase not only in Bangladesh but also globally.

Cons:

- Lower production. It depends on the machine head. The higher the machine head, the higher the production. But recently highly productive machines (MS Lario, EFI Reggiani Bolt) are in the market but it is costly.

- It is not possible to digitally print at any temperature. Have to do digital print in AC room, otherwise, if the temperature rises, the machine will stop automatically and the ink will coagulate and the print head will be damaged.

- The heads of digital printers cannot be reused.

- Printing on deep-dyed fabric is not possible.

6- How do you predict next year for the textile and apparel industry?

Textile & apparel industry is a bit behind due to the global economic crisis and Russia vs Ukraine war. If war doesn’t increase and move to world war, hope from next year the textile and apparel sector will improve and also world economy will become stable.

7- How do you evaluate Bangladesh government support for the textile industry? Is it enough? How government can help Bangladeshi textile manufacturers?

The government always supports for textile industry. If the government doesn’t support the textile sector it never becomes 80% of the country’s total export.

The government start different training & courses to develop mid-level management through the Skills for Employment Investment Program (SEIP).

At present 9 EPZ are running and BEPZA announced that in 15 years 100 EPZ will be established. Recently the government has approved 37 new Economic Zones, which consists of governmental, non-governmental and special economic zone.

Bangladesh is behind in technical and synthetic textiles. If government offer some initiatives like a reduction of tax, prize money, and incentives to entrepreneurs for producing these types of special textile items, hope they will be interested in this new business.

8- At the end, you can add any other information that you think is interesting for readers in the EMEA region and a better interview.

As a textile graduate and experienced in textile I always advise that close supervision is the key to success in the textile sector for improvement of quality & production.

Try to make sustainable the textile sector. Because if we work against our environment, finally we will be the main sufferer of polluting our environment. Plant trees and save the world.

Noman group is alaways best